Picking the right ERP system for your company can be tough because there are many systems out there, each designed for different kinds of work and with their own special features.

Selecting an ERP system can be challenging. In this article, we will help you avoid common mistakes when choosing one for your construction business. We'll suggest essential questions to ask vendors, outline steps to prepare for implementation, and offer advice on considerations to avoid potential issues.

9 Questions to Help You Choose an ERP System

We compiled a list of questions for you to ask construction ERP vendors. These questions will help you learn more about their system and decide whether it fits your needs based on your criteria.

1. How Well Does the ERP Software Help Your Teams Collaborate?

The right software improves collaboration across teams and departments. This includes team members from your organization, subcontractors, and other suppliers. It brings data together across projects and locations, so everyone involved can see what's happening, no matter where they are in the world.

This function comes standard in ERP systems, but feel free to ask your vendor additional questions such as:

-

Does the software offer shared document libraries and chat rooms for team collaboration?

-

Is the platform capable of managing multiple projects in a centralized location, or does it require user to navigate between separate locations for each project?

-

Does the software support task assignment and teamwork, or is an additional tool like Slack necessary for team communication?

2. Do the Benefits Justify the Cost?

An ERP system does not perform a comprehensive cost-benefit analysis by itself. However, it greatly helps in this process with its advanced analytics, reporting tools, and ability to manage finances.

Designed to simplify and bring together different business processes, an ERP offers essential data gathering, instant insights, and financial reporting features. These support the identification of operation inefficiencies and the calculation of possible savings.

For that, you need to ask your software vendor:

-

How and where can I monitor potential savings?

-

What time savings can I expect from this tool?

However, you can also carry out a cost-benefit analysis by identifying all associated costs and projecting benefits like reduced labor costs and improved project timelines. Common costs associated with ERP include:

-

Software licensing fees (for on-premises software)

-

Implementation expenses

-

Training expenses

-

Ongoing costs (including subscriptions for SaaS)

This varies from vendor to vendor so it’s best to ask them for a detailed explanation of all upfront and hidden costs and their associated benefits. Then, you can decide whether the benefits outweigh the price and opt for a software that truly justifies the cost.

3. Is There a Trial Period?

A trial period offers a valuable opportunity to evaluate software prior to making a purchase commitment. During this period, you can explore the software's features and assess how effectively it aligns with business requirements.

Conducting a trial also helps identify any potential issues or bugs. This facilitates prompt resolution before you make a final purchasing decision.

Companies often offer trials and demo versions to their customers upon request. For example, First Bit offers a demo version of its ERP product to help customers become acquainted with the system. Here, you can also ask:

-

How long is the trial period?

-

How limited are the features available during the trial demo-version?

4. How Will It Impact Bottom-Line Results?

When evaluating how an ERP influences bottom-line outcomes, it's crucial to assess how its features enhance efficiency, cut costs, and boost revenue streams. A reliable ERP can simplify project management, supply chain operations, finances, and compliance, ultimately leading to improved profitability and financial well-being for your construction business.

If the vendor claims that the ERP system can control bottom-line results, be sure to ask:

-

Can you provide examples of how your ERP system has helped other construction companies improve their bottom line?

-

How does your ERP system improve project cost tracking and control?

5. Do Other Construction Companies Use It?

Check if other construction companies are using ERP solutions and the benefits they are getting from it. It's important to gather and analyze this information. Ask for case studies from companies that have used the ERP solution you are interested in. This will help you understand how it has been used in other construction projects.

After the supplier has provided you with a strong portfolio and testimonials, you can ask him to give additional information:

-

How long do construction companies typically use your construction ERP system?

-

Did the ERP system make their work easier? How are they measuring the positive results?

6. Does It Handle Procedures Efficiently?

It's important to make sure the ERP system you choose has the right features and can manage them well. It should be accurate, free of errors, and communicate progress in a timely manner.

You can ask:

-

Are there any risks that the system slows down? What can be done to prevent this?

-

Is it possible to receive notifications when some procedures are completed in the system?

7. Can It Scale with Your Project Size?

As your firm takes on larger projects with more subcontractors, suppliers, and multiple sites, you may need to upgrade to a more robust ERP system that can handle multi-currency transactions, project costing, resource scheduling, and compliance with industry regulations.

The adaptability of the system with growing project needs also plays a major role in system selection. Make sure to consider whether the construction ERP system can scale with your business growth. If not, you may be forced to switch systems, leading to project delays and unnecessary expenses. And with that, ask your vendor:

-

In what way does the ERP software scale as our construction business expands?

-

Can your ERP system adapt the additional modules and features needed as our construction projects become more varied and specialized?

8. How Does It Manage Placement and Allocation of Resources?

Resource allocation is the act of dispersing resources like people, tools, and money to different aspects of a project. In an ERP project, this means identifying the required skills and assigning team members with the right expertise to specific roles.

Resource allocation involves distributing resources, such as personnel, equipment, and budget, to various parts of a project. The allocation process entails identifying the necessary skills and abilities and assigning team members with the appropriate expertise to specific tasks. When the supplier answers your main question, ask him for details:

-

Does your ERP system support resource management and scheduling of construction projects?

-

Can your ERP system provide real-time visibility into resource availability and resource allocation to support decision-making processes?

-

How does your ERP system help in forecasting resource requirements and capacity planning to support resource allocation strategies?

9. Does It Support Vertical and Horizontal Systems Integration?

Vertical systems are industry-specific software solutions tailored to meet the needs of a particular sector. For example, if the ERP system is for manufacturing, it might have tools for production planning, inventory management, and quality control.

Similarly, in the construction industry, a vertical integration within an ERP system would be specialized tools for project management, cost control, resource allocation, scheduling, subcontractor management, and compliance with industry regulations.

On the other hand, horizontal systems are general-purpose applications that can be used by companies in various industries. They come with basic functions and are often the main technology system for a company. Other systems can be connected to them for tasks like managing online sales or tracking expenses.

When selecting a horizontal ERP system, check if the vendor can tailor it to meet your specific needs. Horizontal ERP systems serve many industries. Make sure it can cover your unique requirements if the standard package lacks necessary features.

Most modern ERP systems support both kinds of integration. If you want more details, just ask your vendor:

-

Can you show examples how this vertical integration works in real scenarios within similar businesses in our industry?

-

Can your horizontal ERP system easily integrate with third-party applications or systems for seamless data exchange?

-

Can you explain how your ERP facilitates integration with external systems, such as e-commerce platforms, customer relationship management (CRM) software, or supply chain management (SCM) solutions? What standard protocols or APIs does your system use for horizontal integration?

-

If I start a new line of business, can I keep the financial records in the vertical ERP system, or will I need to use two separate systems?

5 Steps to Take Before Choosing a Construction ERP Software

Here is a short plan of steps that you can consider when choosing construction ERP software.

Step 1: Research and Shortlist

During the research step, you usually analyze your old systems, and explore new ones for further integration. Construction ERP systems can vary in their key features, or can be custom-built, so you need to look at the topic from both sides: what needs you need to meet and what the ERP system has to offer.

Research and evaluate vendors to find the best ones. Look for vendors who have experience in the industry and positive customer reviews. Choose vendors that offer important features like planning, estimating costs, scheduling, buying materials, and providing updates in real-time.

Put together an ERP systems selection that interests you. Write down the main aspects of each ERP:

-

Module set. It can be a ready-made set of modules, or a specific set of modules that your business needs.

-

ERP types. This includes: on-premise, cloud-based, custom/hybrid, and generic ERPs. Each has its pros and cons, varying in price and feature set

-

Price. The price depends on the previous two points: the set of modules and the type of ERP. Also take into account the size of your business. It is important to carefully plan your budget at the recertification stage, define your needs and choose a system with a price plan that suits you.

FirstBit ERP software offers various modules to meet customer needs, supports both cloud-based and on-site deployment. It also adapts these modules to suit the unique requirements of your construction business.

Step 2: Vendor Demos and Trials

Demo versions and trial versions are a good way to familiarize yourself with the construction EPP system before purchasing. The trial version usually has a limited set of modules, as more modules would take too much time to customize for you. However, this does not prevent you from getting acquainted with the program interface and its set of features.

Along with the trial version, you usually also get a consulting manager who will walk you through all the modules you are interested in.

Step 3: Appoint a Team

Basically, the implementation team includes representatives from all departments. These are some of the most important departments:

-

Project Management Office (PMO)

-

Finance

-

Operations

-

IT

Forming a dedicated ERP implementation team is crucial for a successful ERP system integration. A project manager leads the team, keeping the project on track, within budget, and addressing challenges. This collaborative effort ensures the ERP aligns with the organization's goals, reduces risks, and guarantees effective use across the company.

Step 4: Design Phase

At this stage you and the implementation team create a detailed design plan for a new construction ERP system, creating new workflows and transferring data from old systems to the new one.

It's important to involve future users like your employees in the design phase, since they have the most intimate understanding of current business processes. If you involve employees at the design stage this will allow them to get acquainted with the system at an early stage. This will make it easier to use later.

Step 5: Implementation Plan

Once design requirements are established, the implementation phase can begin. This phase involves configuring and customizing the construction ERP software to align with the redesigned processes (which were created in the design stage).

Additionally, the implementation may require integrating the ERP system with any other business applications currently in use within the organization. For example, using an on-premises ERP system, the organization must install the required hardware and software.

FirstBit ERP software often includes features that allow integration with other applications, either through built-in connectors or through the use of APIs.

ERP that saves your money

Adopt FirstBit ERP to cut costs, boost ROI, and effectively plan future cash flows

Request a demo

6 Things to Look Out for When Choosing a Construction ERP Vendor

Identify warning signs early to choose a vendor that meets your long-term operational needs and avoids potential pitfalls.

1. Poor Vendor Reputation

Look for negative feedback across software review sites, forums, and social media. Common complaints include poor customer support, leaving users without help for ongoing issues, and unreliable software updates that fail to address the specific needs of the industry.

Complaints about hidden costs surfacing after contract signing are also common. It reflects lack of transparency.

Additionally, a history of failed implementations could suggest that the vendor lacks the expertise or commitment to guide clients through a successful ERP transition.

You should be more concerned if:

-

No customer testimonials and case studies. Many construction ERP vendors showcase customer testimonials and case studies on their websites to increase. If not, this may mean that the ERP software implementation cases were not successful and the expert’s expertise in ERP systems is lacking.

-

Social media and professional networks lack information. LinkedIn, industry-specific forums, and other social media platforms can be valuable to gather informal feedback and opinions on construction ERP vendors. However, if these networks have little to no information on certain vendors, it could indicate a lack of presence or significance in the market.

2. Limited Support and Updates

Limited support can severely impact your operational scalability and continuity, especially in the dynamic field of construction where immediate issue resolution is crucial. A vendor that does not provide 24/7 support or has a reputation for delayed responses can become a bottleneck and cause significant delays to your projects.

Furthermore, infrequent or inadequate software updates can leave your system vulnerable to security risks and may cause your operations to lag behind current industry standards and technologies. This situation can lead to increased costs and decreased efficiency, putting your business at a competitive disadvantage. Make sure that the vendor you choose is committed to regular updates that reflect the latest industry trends and offers comprehensive, responsive support to keep your construction business moving forward without interruptions.

3. Hidden Costs

When choosing an ERP software vendor, watch out for hidden costs that can unexpectedly increase your budget. These costs aren't always clear in the initial price but can appear at different times during the software's use. Key areas to monitor include data migration fees, which can be high based on your data's size and.

Customization costs can also add up if the standard software doesn't fit your needs. Also, remember that some vendors may charge extra for software updates and upgrades, raising the overall cost of owning the software.

4. Ineffective Prototypes

Be wary of vendors presenting ineffective prototypes of construction ERP software. These prototypes might not accurately show the software's complete functionality or how it will mesh with your specific process. Ineffective prototypes can give a false sense of usability, feature set, and integration potential, leading to surprises after purchase.

Consider a project management software demo that only gives a basic overview without tackling real-world project challenges. This demo doesn't accurately show how to track or manage several projects at once.

For example, if you try changing a project's timeline due to unexpected issues, the demo doesn't show how this impacts the schedule, costs, or resource needs. It also lacks instant messaging for team updates, which risks miscommunication. Plus, it doesn't reveal how budget shifts are managed or tracked.

Such weaknesses could result in delays in the project, going over budget, and a decrease in clear communication and responsibility among employees. All of these can seriously affect the project's success and financial health.

Make sure the prototype allows for in-depth testing of essential functions like project management, financials, and reporting. It should also integrate smoothly with any systems or tools your company already uses.

Prototypes lacking in these areas could indicate future problems with setup and customization, impacting project schedules and investment returns.

5. The ERP Requires Excessive Customization

When evaluating potential vendors, a critical red flag to watch for is if the ERP system requires excessive customization to meet your operational needs. Extensive modifications not only significantly increase the implementation time and costs but also complicate future updates and integrations.

Additionally, too much customization can make you rely on the vendor for continuous support and updates, trapping you in an expensive and rigid system. Making too many changes can harm the software usability and its overall performance, as modifications to the original software might cause glitches or compatibility problems.

6. Missed Deadlines

If a vendor misses deadlines during the setup stage, it often shows they're not very reliable or good at managing projects. These delays can mess up your business operations, costing you more money and slowing down your work. Also, if a vendor meets the early deadlines, he might not be quick to help or update the software later on. This situation can leave your construction business dealing with problems and glitches without fast help to fix them.

How the FirstBit ERP Checks All the Boxes

FirstBit ERP stands out as a solution for businesses, particularly in the construction sector, looking to enhance their operations. You'll get support by a diverse team of experts from the moment you begin with us. This includes specialists from our Project Management Office (PMO), Finance Operations, and IT departments. We create a tailored implementation plan that aligns with your specific needs.

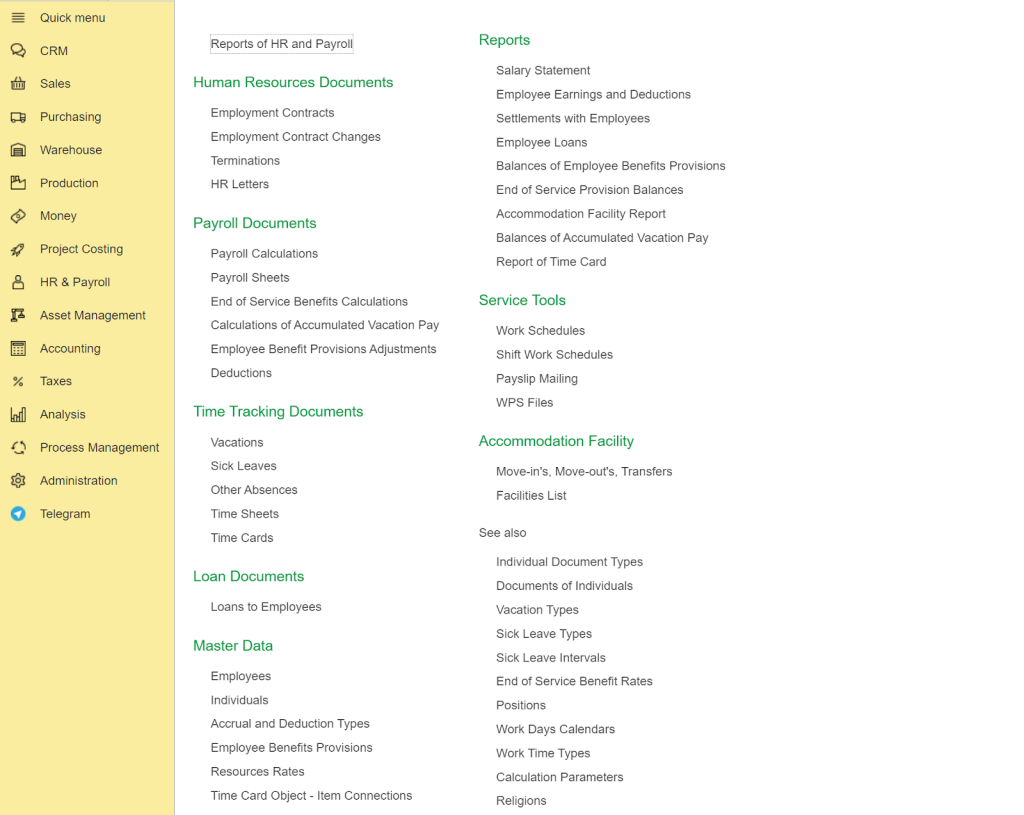

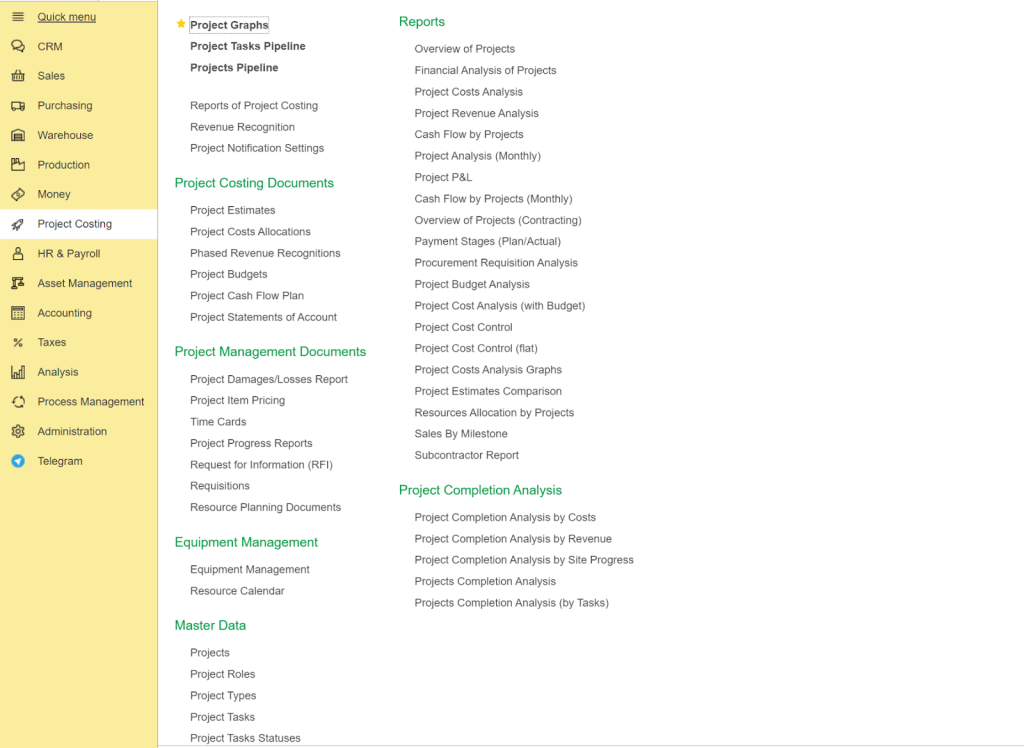

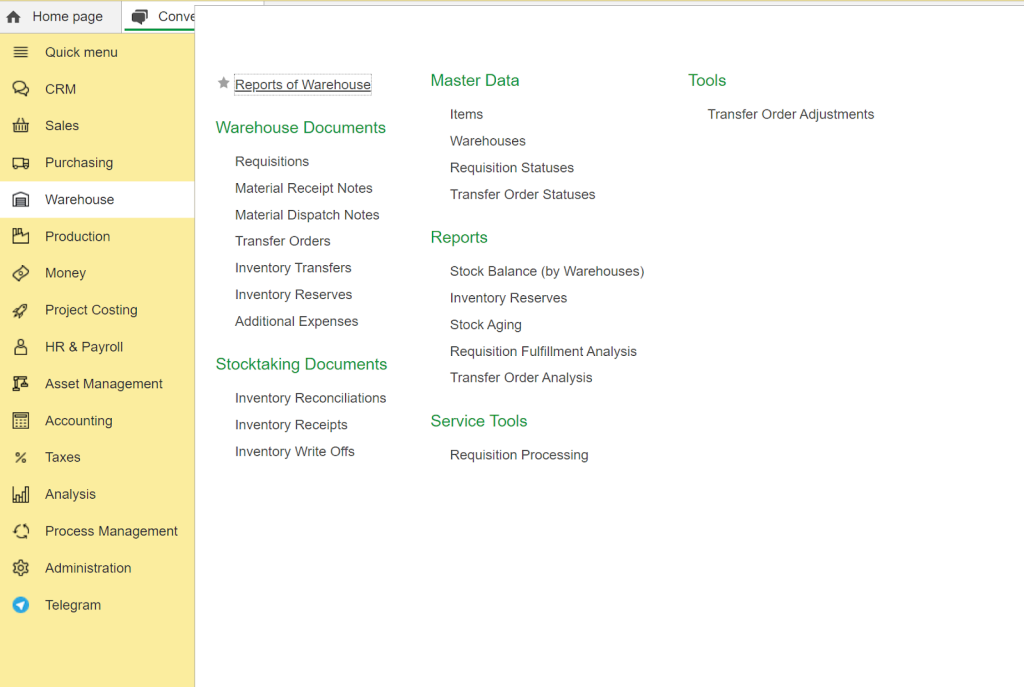

As your projects expand, FirstBit ERP expands adding features and capabilities to match your growing needs without disrupting your existing workflows. Here are the key module set for optimizing your business processes:

Also, First Bit provides helpful case studies on the website, which can be a great resource when choosing a construction ERP system. Through these real-life examples, you'll see the impressive ways FirstBit ERP has driven growth for various construction firms and the advantages they've enjoyed. If you want to streamline operations, make better decisions, or boost client interactions, these case studies clearly demonstrate the potential benefits of implementing FirstBit ERP.

Gain full control of your business

Request a demo

Anna Fischer

Construction Content Writer

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.