Lead time has become one of the most critical and often underestimated risks in construction today. Projects that once relied on predictable procurement cycles now face delays driven by market volatility, factory backlogs, and global logistics issues.

Recent data shows that lead time for construction materials has surged by 25-40% in the past few years, with complex items such as switchgear and precast elements now taking 9-14 months instead of 3-6 months[?].

When long-lead items slip, crews wait idle, schedules shift, and budgets absorb the impact. The result is more uncertainty, more rescheduling, and more pressure on project teams to explain why progress isn’t matching the plan.

That’s why understanding what lead time is, how to calculate lead time accurately, and how to manage high lead time items early in the program is no longer optional. It’s become one of the most important skills for protecting milestones, maintaining client confidence, and keeping construction delivery predictable.

What Is Lead Time

In construction, lead time is the time between realizing you need something and having it ready to use on-site. In practical terms, lead time is every day that passes from the initial request to the moment a crew can actually install the item.

Instead of being only about shipping, lead time is a bundle of smaller pieces:

- Procurement lead time. The time it takes inside your organization to move from a request to a signed purchase order. This includes scoping, getting quotes, internal approvals, and issuing the purchase orders.

- Manufacturing or fabrication lead time. The time the factory needs to produce what you ordered. Standard items may be quick, while long lead materials like custom switchgear, structural steel, or façade systems can have a high lead time that stretches into months.

- Transportation and delivery lead time. The time from the moment the supplier releases the goods to the moment they arrive on site in usable condition. It includes international shipping, customs, local trucking, and any consolidation or off-site storage.

- Internal organizational lead time. The “hidden” time in drawings, approvals, and mobilization. Shop drawings, consultant and client approvals, permits, and subcontractor mobilization can quietly add weeks to total lead time.

Any serious discussion of how to calculate lead time in construction has to combine all these components, not just transit days.

Once you know which piece is slow, you can decide where to push for better terms, earlier approvals, or process changes to change lead time in your favor. If you only focus on one part, you risk a planning mistake similar to lead time bias in statistics, where the numbers look better on paper than in real life.

Why Lead Time Matters in Construction Projects

Once you break lead time into these parts, it becomes clear that it touches almost every area of project delivery.

However, if you misjudge lead time, it not only affects one purchase but also the schedule logic, the cost plan, and how your client feels about working with you.

In fact, long lead-times were shown to increase project delivery costs, reduce value, and degrade decision-making on capital projects[?].

Changes in Scheduling and Critical Path

On a program, lead time shows up as activities that must finish before critical work can start. Items like electrical switchgear, air handling units, or custom curtain wall often sit on or near the critical path, so their dates control many other tasks.

If these items arrive late, several things happen at once:

- Crews cannot finish key areas, which pushes back inspections and handover.

- Planners are forced to resequence work, stack trades, or create temporary workarounds, which increases risk.

- “Float” on other tasks disappears, so small issues start to create real delays.

Even if everything else runs smoothly, one underestimated lead time can decide whether the project finishes on time.

Impact on Cost and Budget

Lead time is also a cost driver. Every extra week of waiting usually shows up somewhere in the project budget.

Typical cost impacts include:

- Expedited freight and rush orders. If something was not ordered early enough, the team may pay for air freight or special deliveries just to stay on schedule.

- Storage and handling. If lead time assumptions are wrong in the other direction and materials arrive too early, you may need off-site storage, extra handling, and additional insurance.

- Labor overtime and inefficiency. When lead time slips, crews may be rescheduled, sent to other areas, or put on overtime to catch up once the material finally arrives. This reduces productivity and inflates labor costs.

- Exposure to price changes. A delayed order can miss a favorable price window. In markets with volatile steel, MEP, or finished pricing, slow procurement increases the risk that the same item will cost more by the time you place the order.

Strong lead time reduction strategies protect both the schedule and the cost plan, so you are not constantly trading extra money for lost time.

Client Satisfaction

Clients usually experience lead time problems as missed dates. From their point of view, it matters less whether the delay came from approvals, a factory backlog, or a shipping issue. It matters that the store, office, or building is not ready when promised.

When lead times are not managed:

- Fit-out and opening dates slip.

- Move-in plans, marketing campaigns, or downstream leases need to be changed.

- The client loses confidence in the team’s ability to control the project.

When lead time is understood, tracked, and actively managed, the effect is the opposite. Milestones are realistic and more often met, which builds trust and strengthens the contractor’s and consultant’s reputation long after the project is complete.

Stay ahead of schedule

Control project timelines through FirstBit

Request a demo

How to Calculate Lead Time

Now that you know what lead time is and why it matters, the next step is understanding how to calculate lead time in a way that your whole team can use consistently.

Once you can measure it, you can start targeting real lead time reduction, instead of guessing where the delays are coming from.

Basic Formula for Lead Time

At its simplest, lead time is just the time between the start of a request and the moment the item is ready to use.

A basic formula looks like this:

Lead Time (LT) = End Date − Start Date

For example, suppose an order for mechanical equipment is placed on January 1 and it is delivered on site, ready to install, on February 1.

Then, you can follow with:

LT = 1 February − 1 January = 31 days

This simple subtraction is the foundation of any lead time calculator you build in a spreadsheet or planning tool. This simple formula forms the basis of any lead time calculator used in spreadsheets or procurement logs to compare planned and actual delivery dates.

Break-down by Components

In construction, a single number often hides where the real problem is. To understand why you have a high lead time on a critical item, you need to break the total into components.

You can think of:

- Pre-processing time. Time spent receiving, understanding, and preparing the order. This includes clarifying the scope, preparing quotes, internal reviews, and issuing the purchase order.

- Processing or manufacturing time. Time spent fabricating or producing the component or equipment.

- Waiting time. Time when nothing is happening because the order is in a queue, waiting for approval, or waiting for the next stage to start.

- Transportation or delivery time. The time it takes for materials or equipment to move from the factory or warehouse to your site.

- Storage time. Time spent warehousing materials before they are actually used in the work.

- Inspection time. Time spent on quality control, testing, and sign-off before the component is approved for installation.

Then, put these components into one expression:

Total lead time = Pre-processing time + Processing time + Waiting time + Transportation time + Storage time + Inspection time

This breakdown shows where and for how long you waited. Looking at only one part of the chain can give a distorted picture, similar to lead time bias in statistics, where results appear better because the starting point was chosen differently.

Lead Time Reduction: Best Practices

Effective lead time reduction is usually the result of consistent planning, coordination, and monitoring rather than last-minute corrective actions.

The aim is to remove avoidable waiting and make sure long lead items are planned and controlled from the outset. When these practices are applied consistently, lead time reduction becomes a proactive process instead of a reaction to late deliveries.

Early Identification and Planning

Lead time reduction starts during tendering, not after construction begins. Long lead items should be logged and tracked in parallel with the main schedule.

Start by capturing the most time-sensitive project components. These usually include:

- Major MEP equipment

- Façade and glazing systems

- Specialist finishes

- IT and AV packages

- Custom or imported materials

For every long lead item you list, make sure the following details are clearly defined:

- Expected lead time

- Required design inputs

- Key approval and decision dates

To avoid gaps between procurement and construction, these dates should be built into the main program:

- Specification finalization

- Inquiry and bid periods

- Internal commercial approvals

- Purchase order dates

- Fabrication and shipping windows

- Delivery to the site

Clear visibility makes responsibility explicit and prevents hidden schedule exposure.

Supplier Engagement and Verification

Planning accuracy depends on real supplier timelines, not assumptions. Early supplier engagement confirms what is achievable based on current factory capacity and logistics.

You can bring more certainty to supplier timelines by following a few essential steps:

Typical candidates include:

- Requesting current lead times and recent delivery examples

- Discussing known risks (material shortages, port congestion)

- Involving designers so decisions reflect lead-time realities

During execution, lead times must be re-validated. Regular updates on production slots, shipment schedules, and logistics changes ensure the planning model reflects reality.

Continuous verification keeps planned lead time aligned with actual market conditions.

Procurement Strategy and Pre-Purchasing

Strategic procurement prevents long lead items from becoming scheduled risks. When contract structure permits, certain items should be purchased ahead of full contract award.

Some materials and equipment often justify early purchasing decisions. Common examples are:

- Generators

- Custom switchgear

- Specialized HVAC units

- Major electrical panels

If speed is a priority, consider using one or more of these approaches to reduce internal lead time:

- Pre-qualification of vendors before award

- Framework agreements with agreed commercial terms

- Consolidated purchasing to secure factory slots

Lead time should be treated as a commercial parameter during negotiation, with clearly defined commitments and consequences.

Removing internal delays increases delivery confidence and protects critical milestones.

Monitoring, Tracking and Adaptive Scheduling

Lead time planning only works if the team tracks performance against the baseline.

To track performance against expectations, your log should record the following:

- Planned vs. actual approval dates

- Purchase order issuance

- Fabrication status

- Shipping and delivery windows

To keep your schedule reliable as lead times shift, build these habits into your planning process:

- Hold dedicated long lead review meetings

- Update the schedule when dates shift, rather than assuming recovery later

- Recalculate critical path impacts and resequence work where possible

Historical tracking reveals patterns such as late internal reviews or consistently delayed suppliers.

Over time, this transforms lead time into a measurable performance metric rather than a reactive problem.

Mitigation Strategies

External conditions can shift unexpectedly. Mitigation strategies minimize schedule impact when lead time increases.

If lead times change unexpectedly, here are several ways to adapt without losing momentum:

- Alternative materials or vendors approved in advance

- Early decisions, such as adjusting specifications, selecting alternate vendors, or approving shop drawings sooner, can significantly change lead time before it becomes a critical-path issue

- Lean planning practices that minimize queue time between tasks

- Fast-track sequencing, where early works proceed while long lead items are in fabrication

- Maintaining backup suppliers for critical components

Contingency options preserve schedule certainty even under changing conditions.

Optimizing Approvals and Internal Processes

Internal workflows often account for more total lead time than manufacturing or transport.

Internal systems often hide delays. Take a close look at the following parts of the process:

- Submittal review cycles

- Mock-ups and sample approvals

- Procurement authorization workflows

Once you’ve identified internal bottlenecks, the next step is to simplify and standardize using methods such as:

- Map all review steps and responsible parties

- Agree on fixed review timelines for critical packages

- Prioritize urgent submittals over routine ones

- Use digital routing and delegated authority to eliminate idle days

- Submit complete, coordinated packages to avoid re-reviews

Improved internal processing shortens total lead time without relying on external acceleration.

Ensure timely and profitable project completion with FirstBit

Request a demo

Lead Time Reduction: Checklist

Reducing lead time keeps projects on track and prevents costly delays. Use this checklist to stay ahead of potential bottlenecks:

- Identify long lead items (typically anything with a lead time over 8–12 weeks)

- Confirm supplier lead times and keep your procurement log updated

- Integrate procurement dates directly into the project schedule

- Set up a clear communication plan with suppliers and subcontractors

- Establish a contingency plan for critical materials and equipment

- Monitor actual vs. forecast lead time weekly to catch issues early

How FirstBit Supports Lead Time Reduction in Real Projects

Controlling lead time requires visibility across procurement, manpower, and equipment. When these elements are managed in one place, delays become predictable and easier to prevent.

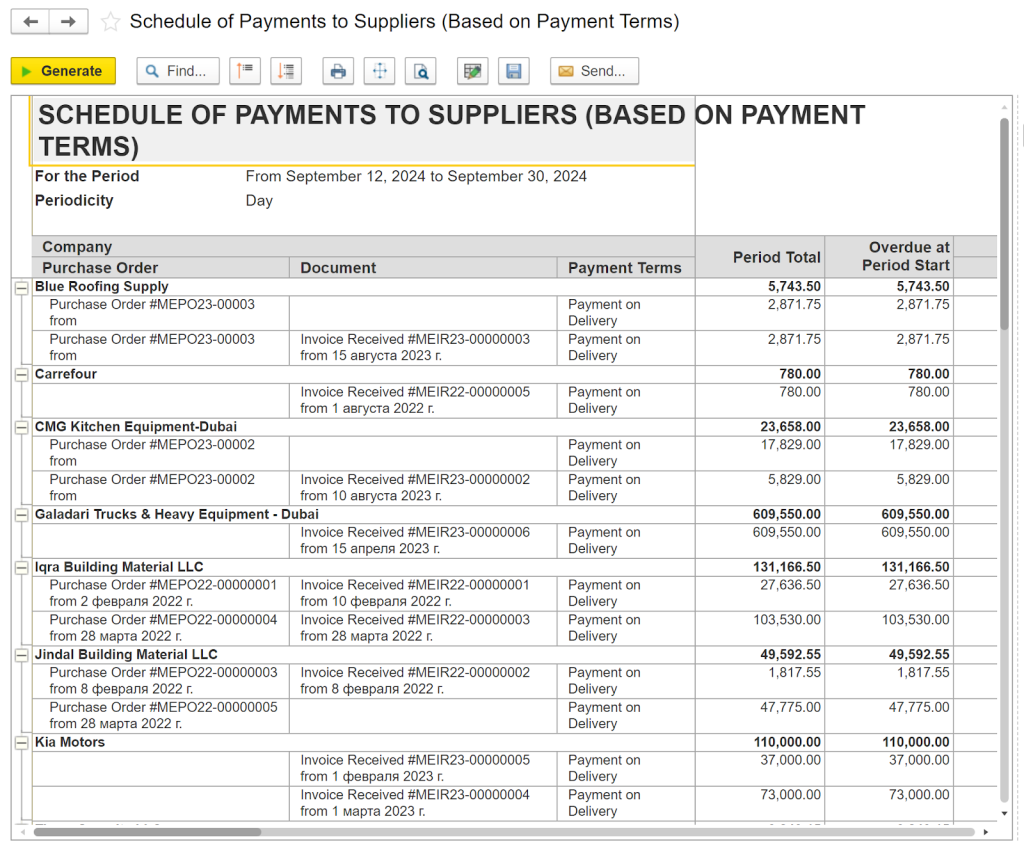

- Real-time visibility into supplier performance. Every purchase order and its payment status is tracked automatically. When delivery dates change, the system updates the expected arrival timeline immediately. This enables project teams to monitor long lead items and determine the exact arrival time of materials, thereby reducing the risk of late deliveries and idle crews.

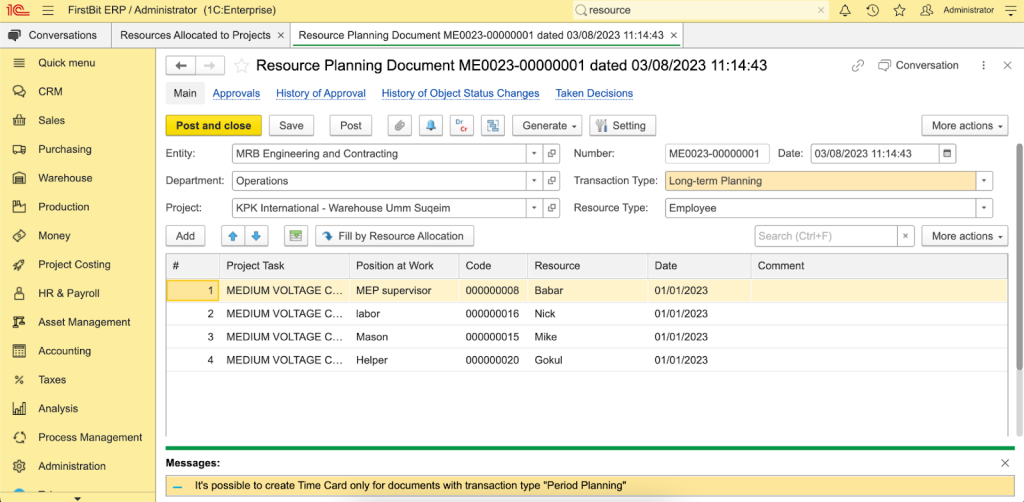

- Lead time control for manpower. If labor allocation is not planned, there will be delays. Resource planning tools allocate employees to tasks based on date, project, and position. This prevents last-minute requests for staff, avoids staffing conflicts, and ensures that critical activities have the necessary personnel available when required.

- Equipment lead time management. Heavy machinery often has the longest lead time due to availability and transport requirements. A live equipment allocation chart shows where each asset is deployed, who is responsible, and until when. If a machine remains on another site longer than planned, project managers see it immediately and can adjust rentals or procurement instead of waiting for delays to surface on site.

Keep your project on track

Manage every phase efficiently with ERP tools

Request a demo

Conclusion

Lead time management plays a central role in keeping construction projects on schedule and within budget. When handled effectively, it allows teams to plan, align procurement with site activity, and reduce the risk of costly downtime. The key is maintaining real-time visibility across suppliers, schedules, and material needs.

Accurate lead time data helps project managers make informed decisions: from selecting reliable vendors to adjusting timelines when delays occur. Understanding how to calculate lead time, monitor discrepancies, and manage high lead time items provides a strong foundation for better resource planning.

With structured tracking and consistent communication, construction teams can reduce uncertainty and create a workflow where materials and equipment arrive exactly when needed, not after.

F.A.Q.

What is Lead Time in simple terms?

What causes a High Lead Time?

What are the most effective strategies for Lead Time reduction?

How can an ERP system help reduce Lead Time?

Stay ahead of delays

Request a demo

Anna Fischer

Construction Content Writer

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.