Managing a warehouse can be incredibly challenging. Handling large inventories, coordinating shipments, and meeting tight delivery deadlines demand constant attention. And when you add outdated systems and unreliable data into the mix, the challenges multiply. This leads to inefficiencies and delays that can be frustrating for you and your team.

Recently, the UAE has seen a surge in warehousing demand, making effective warehouse management more important than ever. If you’re feeling overwhelmed, you’re not alone. Many warehouse managers face similar struggles. The good news is that there are ways to simplify these tasks.

In this article, we’ll explore the top warehouse management system (WMS) software options in Dubai. We’ll also discuss how these solutions can help you streamline your operations, enhance efficiency in your business, and reduce your workload. Let’s dive in.

Understanding Warehouse Management Systems

A warehouse management system (WMS) is a tool that helps you run your warehouse or distribution center more efficiently. It tracks everything from when items arrive at your facility to when they are shipped out. With a WMS, you can easily handle daily tasks, stay organized, and keep your operations running smoothly.

This tool is essential for any business that needs to manage inventory and distribution effectively. In retail and manufacturing, a WMS helps maintain accurate stock levels, speeds up order processing, and reduces errors. In the construction industry, it’s even more valuable.

Construction projects often involve complex logistics, with materials and equipment arriving at different times and locations. A WMS provides the control and visibility you need to manage these resources effectively, ensuring everything arrives on time and avoiding costly delays.

Key Features to Look for in WMS Software

Choosing the right warehouse management system (WMS) can greatly enhance the efficiency of your operations. To find the best option for your needs, here are the must-have features to look for in WMS software.

1. Real-Time Inventory Tracking

Keeping track of your inventory in real-time is essential for smooth warehouse operations. It helps you know exactly what you have on hand and where it is. With FirstBit ERP’s inventory management module, you get instant updates on stock levels and inventory locations. This means you can manage materials and handle requisitions efficiently. This is helpful to avoid issues like overspending or materials shortages.

2. Automation Capabilities

Automation boosts warehouse efficiency by handling repetitive tasks quickly and accurately. FirstBit ERP can help you automate key processes like order picking, packing, and shipping. It generates shipping labels and optimizes packing methods. This can help your business reduce manual errors and speed up fulfillment.

In the construction industry, automation enhances requisition creation and processing. This ensures materials and tools are ordered, approved, and delivered swiftly. Additionally, automating Goods Delivery Notes (GDN) and Goods Received Notes (GRN) allows for real-time tracking and smooth site operations.

For the retail sector, automation simplifies inventory replenishment and manages stock across multiple warehouses, reducing stockouts and improving customer satisfaction. Manufacturing companies can benefit by automating the production line's supply chain. This ensures that raw materials are efficiently managed and minimizes production delays.

Overall, automation in WMS not only increases operational efficiency but also ensures accuracy across different sectors. Whether it’s automating construction requisitions or managing retail stock levels, automation helps businesses stay competitive.

3. Warehouse Layout and Space Optimization

An optimized warehouse layout ensures that items are stored in the most accessible locations. This reduces search times and improves organization.

For example, the FirstBit ERP WMS module offers smart slotting and dynamic bin location management. These features organize items based on size, weight, and usage frequency. These improvements enable your business to operate more smoothly and quickly respond to customer needs.

Top Warehouse Management Systems in Dubai for 2024

If you're looking to upgrade your warehouse operations, it’s helpful to know the best options out there. Here’s a look at the top warehouse management systems (WMS), each designed to meet diverse needs and boost your operational efficiency.

1. FirstBit ERP

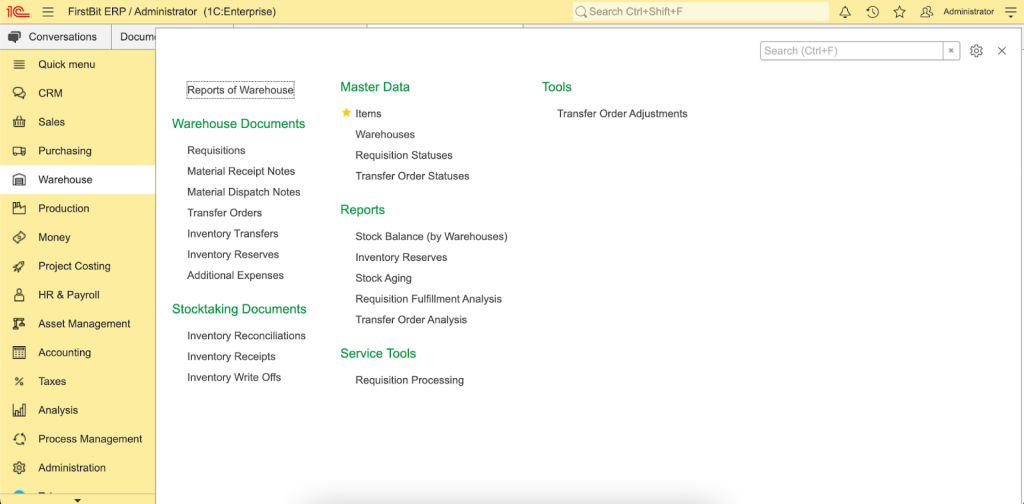

As part of the broader FirstBit ERP suite, this WMS module is designed to streamline and optimize all aspects of inventory management. This ranges from tracking stock levels to automating internal transfers.

Whether you're running a small business or managing large-scale distribution across multiple warehouses, FirstBit ERP provides a powerful solution that integrates seamlessly with other business operations.

It’s ideal for industries such as construction, trading, distribution, and manufacturing and offers flexible deployment options, both cloud-based and on-premise systems. Here’s a look at some of the key features and the unique advantages they offer.

Key Features

-

Multi-warehouse management. Easily handle inventory across multiple locations in the UAE with real-time updates.

-

Automated cost estimation. Reduce financial risks with precise forecasting and procurement tools.

-

Bin location management. Quickly locate items using SKUs, barcodes, or serial numbers, ensuring nothing is misplaced.

-

Internal transfers. Automatically adjust stock levels during inter-warehouse transfers, saving you time and effort.

-

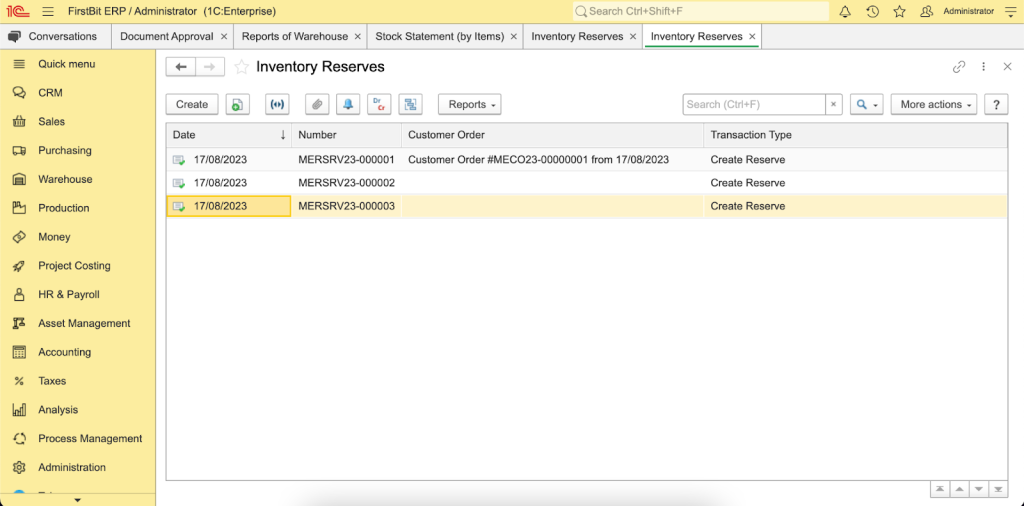

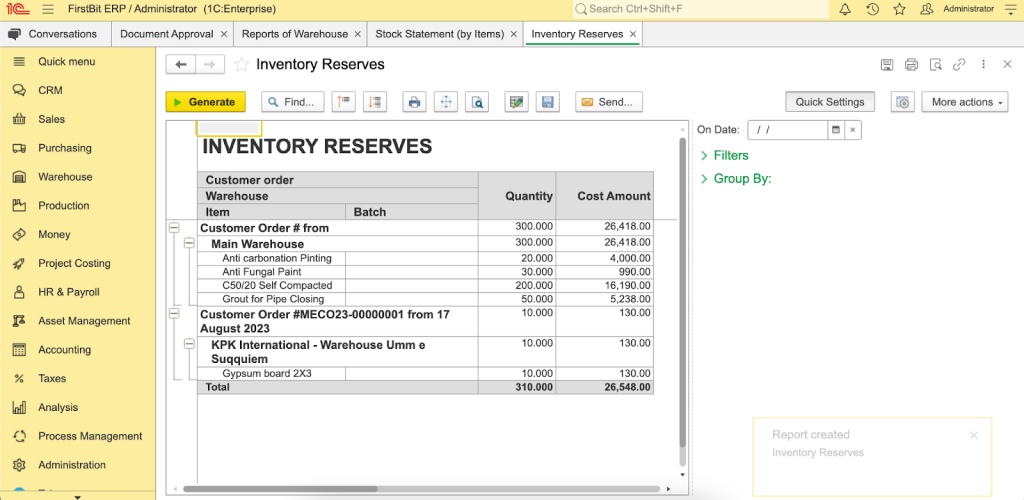

Inventory reservation. Reserve stock for orders ahead of time to ensure prompt delivery.

-

Stock receipt. Access paperless receipts via your mobile browser, simplifying inventory tracking.

-

Expiry date and batch management. Keep track of expiration dates and manage inventory by batch to reduce waste.

-

Barcode and label printing. Print barcodes and labels to maintain an organized and easily trackable inventory.

If you are in the construction industry, you can manage inventory across multiple sites, ensuring efficiency and transparency in the supply chain:

-

Generate material receipts and dispatch notes

-

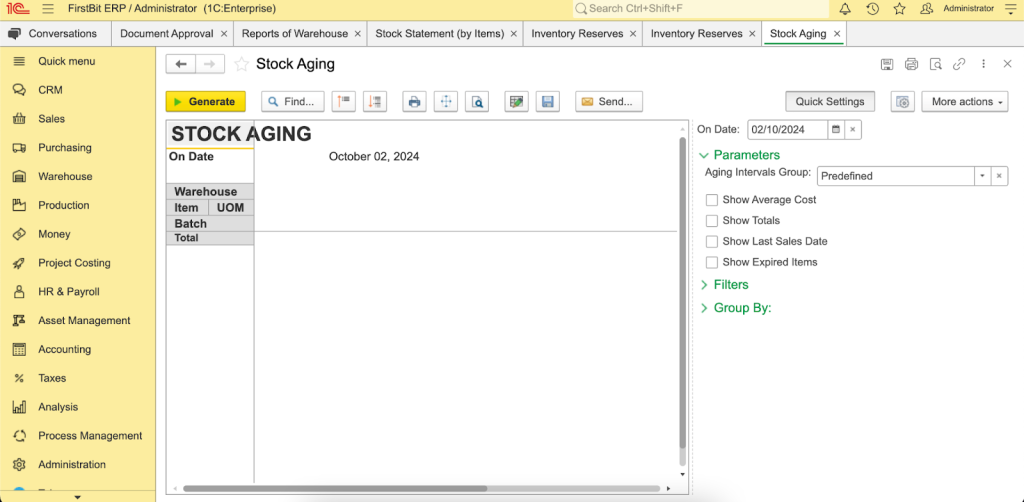

Optimize warehouse management in your construction company by tracking stock aging and managing inventory stock transfers and consumption

-

Log all transactions without discrepancies

Pros

-

Offers real-time stock management across multiple locations.

-

Inventory reservation and transfer based on requisitions ensure timely availability of materials for construction projects.

-

Automatically generated material receipt and dispatch notes simplify inventory tracking and audits.

-

Real-time visibility into inventory levels, aging, and usage.

Cons

-

Initial setup can be time-consuming, requiring accurate data and planning.

-

Full functionality may require investing in barcode scanners, handheld devices, and label printers, increasing upfront costs.

-

Staff may require continuous training, especially in high-volume projects.

-

It may require additional customization and setup time.

2. Zoho Inventory

Zoho Inventory offers a powerful and flexible platform for businesses looking to streamline their inventory management across multiple channels and warehouses. Whether you’re managing physical products, offering dropshipping services, or handling backorders, Zoho Inventory provides robust tools for all your needs.

The system is designed to cater to businesses of all sizes, offering scalability, ease of use, and seamless integration with various sales and shipping platforms. For businesses using digital storefronts or working with international customers, Zoho Inventory supports multi-channel selling, multiple currencies, and real-time shipping integrations to ensure smooth operations and customer satisfaction.

Key Features

-

Centralized inventory. Updates stock automatically across all channels after each sale.

-

Automatic re-ordering. Set reminders and re-order points to avoid stock-outs.

-

Barcode management. Scan barcodes to auto-fill fields for invoices and orders.

-

Serial number tracking. Track items from purchase to sale with unique serial numbers.

-

Batch and expiry tracking. Monitor batches and expiry dates for freshness.

-

Multi-location warehousing. Manage multiple warehouses and stock flow in one app.

Pros

-

Integrates smoothly with popular platforms like Amazon and eBay.

-

Track inventory levels in real-time across multiple locations.

-

Real-time integration with shipping carriers.

-

Its multi-currency feature is perfect for businesses operating internationally.

Cons

-

The lower-tier pricing plans restrict the number of users and warehouses you can manage.

-

Highly specialized businesses may find that some of their unique requirements need additional customization or third-party integrations.

-

Businesses with large or complex inventory systems may need time to configure all settings and integrate them with other software.

-

The mobile app can be made better.

3. NetSuite Warehouse Management

The NetSuite Warehouse Management System (WMS) optimizes daily warehouse operations using industry-leading practices such as mobile RF barcode scanning, defined strategies for putaway and picking, task management, return authorization receipts, and cycle count plans.

It addresses the chaos often associated with managing hundreds or thousands of SKUs across multiple locations, allowing businesses to minimize handling costs and operate more efficiently while consistently meeting customer expectations. Let’s take a look at some of the features.

Key Features

-

Inbound logistics. Receive items accurately with mobile scanning and organized storage strategies.

-

Order fulfillment. Speed up order processing with smart pick-and-pack methods.

-

Mobile management. Handle daily tasks like receiving and packing right from your mobile device.

-

Bin management. Easily manage inventory with or without bins.

-

Cycle counting. Automate inventory counts with Smart Count, which adjusts in real time for any changes.

Pros

-

Using mobile devices helps capture item, lot, and serial numbers correctly when receiving goods, which reduces mistakes in data entry.

-

Provides real-time tracking of stock.

-

Organizes warehouse space efficiently by keeping fast-moving items close to fulfillment areas, which maximizes storage use.

-

Mobile guidance helps warehouse staff complete tasks more effectively.

Cons

-

The one-time setup fee for getting started can be high.

-

Staff may need training to get used to the mobile app and new processes.

-

Relying on mobile technology can be tricky if devices fail or if there are connection problems.

-

Businesses using systems outside of NetSuite may have trouble integrating.

4. Axolon ERP

Axolon Inventory Management software is designed to optimize inventory operations for businesses with multiple locations, particularly in Dubai. With its advanced features, this software allows companies to monitor stock movements and manage inventory across various sites seamlessly.

By providing real-time visibility into stock levels and allocations, Axolon ensures effective inventory management throughout the organization. This capability is essential for making informed purchasing and reordering decisions, allowing businesses to maintain optimal stock levels based on predefined thresholds or demand forecasts.

Moreover, Axolon enhances the procurement process by enabling users to create purchase orders, manage suppliers, and monitor the entire procurement workflow. By streamlining these processes, businesses can ensure they have the right products available at the right time, reducing the risk of stockouts or overstocking. It offers some useful features.

Key Features

-

Multi-location management. Track stock levels and movements across all sites.

-

Smart reordering. Automate reordering and manage suppliers efficiently.

-

Advanced inventory. Predict seasonal demand and spot patterns early.

-

Batch and expiry tracking. Get automatic lot tracking and expiry reminders.

-

Integrated barcode system. Eliminate manual entries with built-in barcode scanning.

-

Multi-warehouse management. Transfer items with a 3-step process and monitor stock in real-time.

Pros

-

Offers real-time tracking of inventory.

-

The integrated barcode system minimizes manual errors.

-

The intuitive design of Axolon makes it easier for staff to adapt to the system, leading to quicker onboarding and improved productivity.

Cons

-

The implementation of Axolon may require significant upfront investment.

-

The reliance on software and mobile devices may pose challenges in the event of system failures or connectivity issues.

-

Companies using other software solutions may face challenges integrating Axolon with their existing systems.

How to Choose the Right WMS for Your Business

Finding the right warehouse management system can improve your warehouse operations and boost overall efficiency. Here’s a straightforward guide with practical examples to help you select the best WMS for your business.

1. Evaluate Your Needs and Budget

-

Understand your requirements. Start by identifying what your warehouse needs. For example, if you manage a large number of products and multiple locations, you might benefit from the real-time stock tracking and multi-warehouse management features.

-

Consider scalability. Choose a system that can grow with your business.

-

Assess complexity. Match the WMS’s complexity to your operations.

-

Budget wisely. Set a budget that covers both initial costs and ongoing expenses. Compare WMS options to find one that fits your financial plan.

FirstBit ERP specifically addresses all the above-mentioned warehouse needs by offering advanced real-time stock tracking, multi-warehouse management, and automated inventory updates, which ensures seamless operations across multiple locations.

It also offers cloud-based options that can adjust as your volume increases, helping you avoid major system changes and expensive upgrades down the road. With transparent pricing, it helps you manage both initial implementation and ongoing costs effectively.

2. Choose the Right Vendor

-

Evaluate customer support. Good customer support is really important when it comes to business. Choose a vendor that has responsive customer service and also offers helpful training resources.

-

Read reviews and case studies. Look at reviews and case studies to gauge the vendor’s effectiveness.

3. Look for Industry-Specific Features

Select a WMS that caters specifically to your industry, especially if you’re in construction. Features such as project-based inventory tracking, resource allocation, and compliance with construction regulations can greatly enhance your operations.

Tailored functionalities will help you manage materials and equipment efficiently, ensuring you stay on schedule and within budget. For instance, FirstBit’s WMS module offers many features suited to the construction industry.

4. Ensure compliance with local laws

It’s essential to choose software that complies with local regulations, particularly in industries with strict compliance requirements like construction. FirstBit’s ERP system adheres to IFRS standards, VAT regulations, and other local regulations, including tax laws and data protection requirements in regions like Dubai.

Understanding and adhering to regulations helps avoid costly fines, legal disputes, and project delays, which can negatively impact both reputation and financial stability. Additionally, adhering to regulations fosters trust with clients and stakeholders, promoting long-term business success.

5. Consider Deployment Options

Decide between cloud-based vs. on-premise systems. While on-premises solutions can offer greater control over data and customization, advanced cloud solutions like FirstBit’s provide similar benefits while also delivering the advantages of cloud technology, such as remote access and flexibility. As a result, many companies are increasingly opting for cloud-based systems to enhance their operational efficiency and scalability.

By carefully evaluating your needs and considering different vendors, you can find a WMS that fits your business perfectly.

Why FirstBit ERP is Your Best WMS Solution

To sum up, choosing the right warehouse management system (WMS) can transform your warehouse operations. A good WMS keeps your inventory updated in real-time. It automates routine tasks and helps you organize your warehouse effectively.

This system also simplifies order fulfillment and leads to increased productivity.

FirstBit ERP stands out as a top choice for your WMS needs. It offers real-time inventory tracking, robust automation capabilities, and smart warehouse layout optimization. Whether you need flexible deployment options or industry-specific features, FirstBit has you covered.

F.A.Q.

1. What industries can benefit from using FirstBit ERP’s WMS?

FirstBit ERP’s WMS offers features specifically designed to address industry needs, like for construction, it offers features such as project-based inventory management, tracking of materials by job site, and integration with project management tools.

For other industries, such as manufacturing and distribution, features like consignment stock processing and batch management are more relevant. This distinction helps businesses in each sector leverage the specific functionalities that best meet their operational requirements.

2. How does FirstBit ERP’s WMS ensure compliance with local regulations?

FirstBit ERP’s WMS complies with IFRS standards and local regulations, including tax laws and data protection requirements in regions like Dubai. This ensures that your operations meet legal and industry standards.

How do I get started with FirstBit ERP’s WMS?

To get started with FirstBit ERP’s WMS, you can request a demo. Our team will walk you through the features and help you see how it fits your business needs.

Umme Aimon Shabbir

Editor at First Bit

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.