If you’ve ever put together a Request for Quotation (RFQ) for a construction project, you know the struggle. You spend hours detailing requirements, sourcing vendor lists, and ensuring every spec is covered—only to receive incomplete quotes, overpriced bids, or worse, total silence.

Why does this happen? Because the RFQ process isn’t just about asking for prices—it’s about getting the right vendors to respond with competitive, accurate proposals. And that’s where many construction businesses hit roadblocks. Vague scopes, unclear timelines, or missing details can lead to wasted time, confusion, and expensive project delays.

If you’re tired of RFQs that don’t bring the results you need, this guide is for you. We’ll break down how to structure RFQs that attract qualified bidders, reduce back-and-forth emails, and get you the best value for your projects without the usual headaches. Let’s dive in.

What is an RFQ in Construction?

A Request for Quotation (RFQ) in construction is a document that project owners or contractors send to suppliers, subcontractors, or service providers to get price estimates for specific materials, equipment, or labor. It is used when the requirements are clear and well-defined, and the main goal is to get the best price for a particular service or product.

For example, if a contractor needs 500 cubic meters of ready-mix concrete for a building foundation, they will send an RFQ to multiple suppliers detailing the exact quantity, delivery schedule, and specifications. Each supplier then responds with a price quote, allowing the contractor to compare costs and choose the most competitive option.

RFQs are common in large construction projects where materials can make up 40-60% of total project costs.

Unlike a Request for Proposal (RFP), which asks vendors to suggest solutions and approaches for a project, a Request for Quotation (RFQ) is used when the project requirements are already set and the only thing left to determine is the price.

In an RFP, vendors are expected to provide not just pricing but also detailed plans, methodologies, and recommendations on how they would complete the work. This is useful when a project is complex and the buyer needs expert input to finalize the approach.

An RFQ, on the other hand, is straightforward—it is sent when the buyer knows exactly what they need (such as a specific type of concrete or a set number of steel beams) and simply wants vendors to quote their best price for supplying it. This makes RFQs faster and more focused on cost comparison rather than strategy or innovation.

Purpose of an RFQ in Construction

RFQs in construction streamline the procurement process by ensuring all the requirements for a project are clearly stipulated. RFQs make the bidding process both transparent and competitive.

An effective RFQ process in your business will help you achieve the following objectives:

-

Cost comparison. RFQs provide you with a standardized method to compare costs from suppliers and contractors. You will get detailed quotes and competitive bids, allowing you to find the most cost-effective options (without sacrificing quality).

-

Supplier selection process. With a detailed RFQ, you will find it easier to select the most skilled and trusted suppliers and contractors for your project. The outlined requirements within your RFQ will draw potential partners with the qualifications and expertise you need.

-

Contract negotiation and terms. Each RFQ creates a foundation for contract negotiations. You can identify and clarify specific terms with contractors and vendors before entering into official agreements. These terms include pricing, project scope and timeline, and deliverables.

Key Components of a Successful RFQ

Writing a successful RFQ requires a structured approach and attention to detail. It also means that your RFQ should contain the following information:

1. Clear and Detailed Project Specifications

Every RFQ should start with basic project information so vendors understand the scope and location of the work. Providing context helps suppliers assess logistics, delivery feasibility, and cost factors. Essential details include:

-

Project name and location. Clearly states where the materials or services will be needed.

-

Project timeline. Outlines key dates, including the deadline for quotes and expected delivery or service completion.

-

Project owner or contractor information. Includes contact details in case vendors need clarifications before submitting their bid.

2. Scope of Work and Specifications

One of the most important parts of an RFQ is a detailed description of the materials, services, or equipment required. Vendors rely on this section to understand exactly what they need to supply. The more specific the RFQ, the more accurate the bids will be. Key details include:

-

Exact materials or services needed. The RFQ should list all required materials, including type, quantity, and quality standards.

-

Technical specifications. Any industry standards, certifications, or compliance requirements that materials or services must meet.

-

Work conditions and site requirements. Special handling, on-site constraints, or installation conditions that suppliers must consider.

Example: If requesting steel beams, the RFQ should specify dimensions, grade (e.g., ASTM A36), weight per meter, and surface treatment (e.g., galvanized or painted). This avoids ambiguity and ensures accurate quotes.

3. Pricing Request

The RFQ should be designed to capture clear and competitive pricing from vendors. It should specify how pricing should be structured so that bids are easy to compare. This section typically includes:

-

Unit prices. Vendors should provide per-unit costs (e.g., cost per ton of steel, cost per cubic meter of concrete).

-

Bulk pricing (if applicable). Discounts offered for larger orders or long-term supply agreements.

-

Total cost estimates. The final expected cost based on required quantities.

-

Delivery and logistics costs. Any additional charges for transportation, storage, or handling.

4. Submission Requirements

To streamline the bidding process, the RFQ should clearly state how and when suppliers must submit their quotes. This prevents last-minute confusion and missed deadlines. Essential submission details include:

-

Deadline for quotes. The exact date and time by which vendors must submit their bids.

-

Format of submission. Whether quotes should be submitted via email, an online procurement system, or as a physical document.

-

Required documents. Certifications, licenses, proof of previous work, or any compliance documents necessary for qualification.

5. Evaluation Criteria

Since cost isn’t the only factor in vendor selection, the RFQ should outline the criteria that will be used to evaluate bids. This helps suppliers understand what matters beyond price. Important factors include:

-

Price comparison. Whether the lowest bid automatically wins or other factors influence the decision.

-

Delivery timelines. If preference is given to vendors who can meet specific deadlines.

-

Quality and reputation. Whether vendor experience, past performance, or customer reviews will be considered.

6. Terms and Conditions

To avoid disputes, the RFQ should list payment terms, penalties, and any legal obligations that apply to the purchase. This section ensures vendors understand their responsibilities before submitting a bid. Key terms may include:

-

Payment terms. When and how payments will be processed (e.g., advance payments, milestone-based payments, or net-30 terms).

-

Penalties for delays. Consequences if a vendor fails to deliver on time.

-

Warranty and after-sales support. Requirements for product warranties or ongoing service agreements.

A well-structured RFQ ensures all vendors provide comparable bids, reducing the chances of cost overruns and procurement delays. It also minimizes back-and-forth clarifications, making the entire process smoother and more efficient.

Align every purchase with project goals

Track supplier performance and control costs

Request a demo

Best Practices for Creating RFQs

You can maximize the effectiveness of your RFQ process by implementing the following best practices:

1. Use a Standardized Format

A structured RFQ format makes it easier to compare vendor responses. Include a detailed scope of work, pricing breakdown, and payment terms to ensure consistency. Clearly outline submission guidelines, deadlines, and any additional documentation required, such as compliance certifications or past project references.

2. Invite the Right Vendors

Sending RFQs to vendors who lack the capacity or experience for the job leads to poor-quality bids. Select suppliers based on their past performance, industry reputation, and ability to meet project requirements. Ensure that they have the necessary certifications and financial stability to fulfill the order without delays.

3. Set Realistic Timelines

Rushing vendors to submit their bids often results in incomplete or inaccurate quotations. Provide them with enough time to assess the requirements properly, prepare competitive pricing, and clarify any uncertainties. A well-planned timeline ensures better participation and higher-quality proposals.

4. Avoid Overloading Vendors With Unnecessary Details

While an RFQ should be comprehensive, it should not overwhelm vendors with excessive information. Focus on essential details required for accurate pricing and service delivery. Keep the document concise while ensuring it covers all critical aspects of the request.

5. Establish Clear Communication Channels

Vendors often have questions before submitting their bids. Provide a designated point of contact for inquiries and set a deadline for clarification requests. If necessary, schedule a pre-bid meeting to address concerns and ensure all potential vendors fully understand the RFQ requirements.

6. Digitize the RFQ Process for Better Tracking

Using procurement software or cloud-based RFQ management systems can streamline the process.

Digital tools help automate RFQ distribution, track vendor responses, and reduce errors. They also make it easier to compare bids, ensuring all required details are submitted correctly.

7. Follow Up and Provide Feedback

Once a vendor has been selected, inform unsuccessful bidders of the decision and provide constructive feedback. This fosters stronger relationships and encourages higher-quality participation in future RFQs.

Providing feedback also helps vendors understand how they can improve their bids next time.

8. Regularly Review and Improve RFQ processes

Analyzing past RFQs can reveal inefficiencies or areas for improvement. Identify bottlenecks, evaluate vendor response rates, and adjust the process to improve bid accuracy.

Refining RFQ strategies over time leads to better procurement outcomes and reduced project risks.

Tools and Software for Successful RFQs in Construction

Using the right software tools can vastly improve your RFQ process. Digital solutions allow you to streamline repetitive tasks such as cost estimation and drafting. These tools can also help you manage submissions and evaluate suppliers.

Some of the most effective tools include the following:

1. Digital Tools for Precise Cost Estimation

Accurate cost estimation is a must for RFQs. A digital cost estimation tool can help you refine the process with cost databases and customizable templates. You can enter pricing data for material and labor (and other costs) and make accurate calculations based on current market conditions.

You can also use digital tools to create various cost scenarios. When you adjust variables like material or labor pricing, you can better understand how changes will impact project costs.

Moreover, automation reduces human error, producing a more reliable and consistent output.

2. Software for RFQ Drafting and Management

Specialized software can help you streamline the drafting and management process. This type of software usually includes a centralized document management platform. This platform can store all RFQ documents, making them more accessible.

These tools typically also include a management platform allowing seamless communication between stakeholders. Project managers, suppliers, and contractors can connect and collaborate in real-time, providing updates and clarifications during the project timeline.

You will also be able to track the status of RFQs while monitoring deadlines. This feature helps pinpoint bottlenecks and potential delays early in the project timeline.

You may even find a software tool that compares and evaluates supplier bids. You can easily analyze and select the best options by entering predefined criteria.

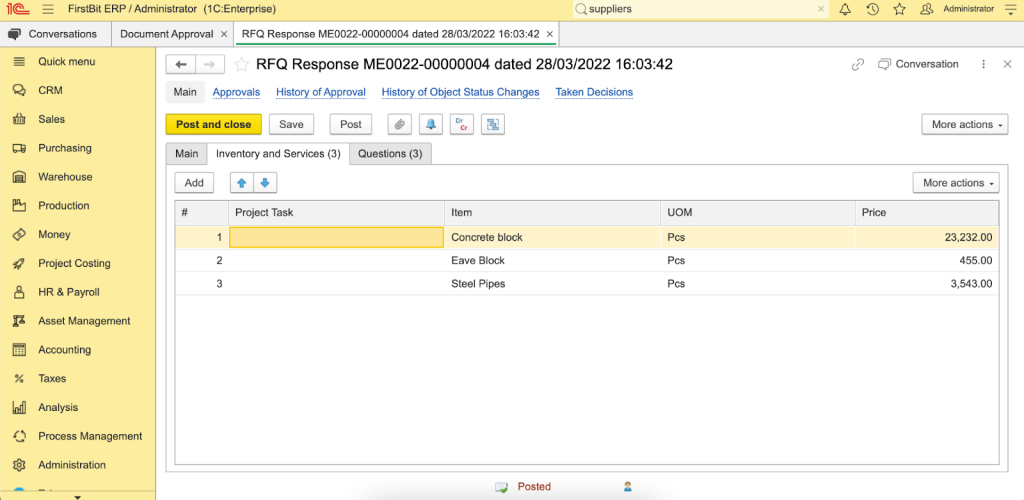

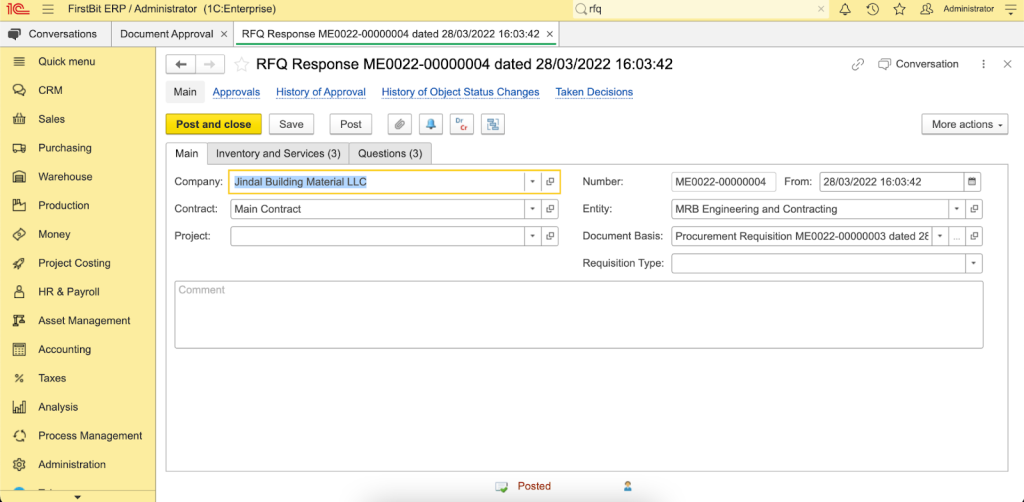

3. Using ERP Systems for a More Efficient RFQ Process

Enterprise resource planning systems (ERP) like FirstBit ERP provide an integrated approach to managing several construction business functions, including RFQs. With FirstBit, you can keep your procurement and supplier management processes on track.

The software is designed to streamline construction project operations by providing instant access to project data. You will improve communication and reduce inefficiencies across several departments involved in the RFQ and project management process.

FirstBit ERP gives you centralized data access and automates the various workflows involved in the RFQ process. This includes sending RFQ requests, receiving the responses, and sending submission reminders.

You can use the software to create and maintain a database of suppliers. This is convenient and ensures that your suppliers meet the criteria for various RFQs.

FirstBit ERP also provides an analytics and reporting function, allowing you to track RFQ status and responses. You can integrate FirstBit software with existing business systems for a complete construction and RFQ management tool incorporating finance and accounting elements.

Get top-quality materials at the best prices for your construction project

Request a demo

Cedric Jackson

Contributing Author

Related terms

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.