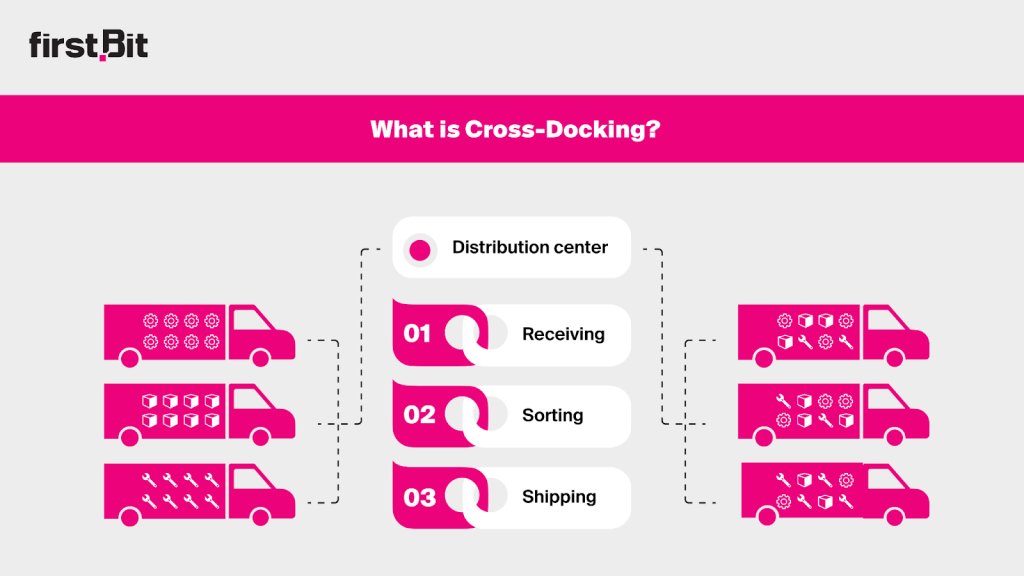

Construction delays often start with slow material movement, overcrowded storage, and poor timing. Cross docking solves this by eliminating unnecessary warehousing steps and keeping materials in continuous motion. Instead of receiving, storing, and picking items, the cross docking process transfers goods directly from inbound trucks to outbound vehicles.

This simple shift reflects the core cross dock meaning in logistics: fast flow, minimal storage, and fewer handling costs. For contractors working in busy UAE project environments, cross dock shipping helps materials arrive exactly when needed.

In this article, we explain what cross docking is, why it works, and how modern tools, especially cross docking software, support smoother, more predictable construction logistics.

What Is Cross-Docking in Logistics

In cross-docking, inbound goods are transferred directly to outbound transport, with minimal time spent in storage. In an efficient operation, products can be transferred from one truck to another in just a few hours.

This means you don't need to do the putaway, the picking, all those slow, expensive steps that traditional warehousing relies on. This is the practical cross dock meaning in logistics, where the focus shifts from long storage cycles to fast, coordinated movement.

In a conventional warehouse, pallets are received, checked in, and stored. They are then picked and prepared again for dispatch. Each step incurs labour costs and handling time, not to mention the risk of misplacing or damaging stock. With the cross-docking, the facility becomes more of a flow-through terminal than a storage location. This works especially well when demand is predictable, and the timing of inbound and outbound transport can be aligned.

However, cross-docking is not a replacement for warehousing. It is a different operating mode that only makes sense when incoming goods are already allocated and labelled for a customer or route, or known to be moving out immediately. When these conditions are met, cross-docking keeps inventory low and transit times short.

Types and Variants of Cross-Docking Process

There is no single fixed method of cross-docking. Rather, operators adapt the process according to the type of freight and the predictability of downstream demand. Many facilities rely on cross docking software to manage these shifts, ensuring inbound and outbound allocations stay aligned even when demand varies.

Here are the differences between the pre-distribution and post-distribution cross docking process:

- Pre-distribution is effective when the inbound shipment is already allocated upon arrival. The labels match the customer or route, and the workers mainly focus on transferring the freight from one side of the dock to the other. This is common among retail suppliers who deliver to chains with weekly order cycles, where quantities are planned in advance.

- Post-distribution is more flexible. Goods arrive in bulk, and allocation occurs inside the cross-dock. Staff break down pallets and sort products by order or store before reassembling outbound loads. Grocery networks and e-commerce hubs rely on this approach because demand can change quickly and allocations can be subject to last-minute changes.

Apart from the different cross docking processes, there are also different mods: continuous, consolidation and reconsolidation:

- Continuous flow is the simplest version. Inbound and outbound trucks are scheduled so that freight can move directly across the dock with minimal staging. This works when volumes are steady, and transport partners stick to the schedule.

- Consolidation mode is used when several small inbound shipments need to be combined into a single outbound load. For example, this would be used when multiple suppliers send partial pallets to the same destination store. The cross-dock then becomes the point at which these flows are merged efficiently.

- Deconsolidation mode is the opposite. One large inbound load is broken into smaller outbound loads, which are often aligned to final-mile routes. A typical scenario is international freight arriving in container loads.

Hybrid / Opportunistic Cross-Docking

Most real-life operations use a hybrid system. Some loads are transported directly, some require quick sorting and some are temporarily stored because an outbound truck is running late. This is often referred to as “opportunistic cross-docking” because the team uses this method whenever conditions allow, rather than applying it to every shipment. Many third-party logistics (3PL) facilities adopt this model to stay flexible across different clients and freight patterns.

Case study

A peer-reviewed study of a global oilfield services company that used Jafza as its hybrid cross-dock found that jointly optimizing inbound shipments from China, Houston, and the Netherlands lowered total logistics costs while keeping the flow predictable[?]. The ability to use short, cost-free storage windows added flexibility without pushing unnecessary inventory into the plants.

As a result, the company was able to stabilize supply across seven Middle East production sites despite volatile demand and long lead times.

Key Requirements and Preconditions

Cross-docking works only when a few fundamentals are in place, and these apply whether you run a traditional setup or a hybrid cross dock model.

To keep the flow stable and prevent the dock from turning into short-term storage, meet a few conditions:

- Reliable schedule synchronization. Transport timing is crucial. If inbound trucks arrive early and outbound trucks arrive late, your dock will fill with pallets, causing you to lose the advantage of cross docking. Teams that use cross-docking effectively usually invest in accurate slot booking, strong carrier communication, and real-time visibility of truck movements.

- Visibility and integration with partners. Suppliers, carriers, and customers must share accurate data. The receiving team needs to know what is arriving, in what quantities, and how it is allocated. If an inbound load does not match the plan or labels are incomplete, the entire process slows down. This is one reason many companies use cross-docking software to align information across partners.

- Infrastructure, handling equipment, and information systems maintenance. A true cross-docking facility has more dock doors, faster staging areas, and equipment designed for rapid movement rather than storage. Essential tools include pallet jacks, conveyor lines, and a warehouse management system (WMS) that supports quick check-in and error-free scanning. Since cross docking is about continuous movement, the physical layout must allow freight to travel smoothly from inbound to outbound.

- Skilled labor and operational discipline. Cross docking leaves little room for sloppy work. Staff must be trained to quickly identify, correctly route, and safely move freight at speed. Even small mistakes ripple through the network because products are not held long enough to correct errors later.

Application in Construction Logistics

Cross docking in construction is used to keep the jobsite clear and ensure materials arrive exactly when crews need them. Instead of moving materials through a warehouse, the cross docking process routes them through a central transfer point so they go straight to installation.

Construction Supply Chain Flow and Cross-Docking Process

Construction supply chains run through predictable stages. Suppliers or fabrication plants prepare materials, a cross-dock receives and sequences them, and outbound trucks move them directly to the jobsite.

Staging yards near the site often serve as the final timing point, aligning deliveries with daily work schedules. This setup improves flow without turning the site into a storage zone.

Material Types Suited for Cross-Dock Shipping in Construction

Cross dock shipping is well-suited for items that need to arrive in a specific order. Prefabricated assemblies, structural steel, and MEP components are good examples because they move quickly from truck to installation.

Bulk loads such as rebar, pipes, and cables fit the model when quantities are known. Materials sensitive to temperature or moisture, such as coatings or finishes, also benefit because they avoid unnecessary handling and exposure. These categories move especially well through cross dock shipping because they require minimal touchpoints and are often delivered in a pre-planned sequence.

Benefits of Cross-Docking in Construction

Cross docking offers several practical advantages for construction projects because it keeps materials moving instead of sitting in storage.

To understand where these gains come from, the key benefits can be broken down into the following points:

- Lower inventory and handling costs since materials do not accumulate on the ground or in a warehouse.

- Faster cycle times and better cash flow because items move directly to installation instead of waiting in storage.

- Better consolidation and delivery accuracy through smaller, more frequent, and installation-aligned shipments.

- Higher handling capacity with minimal space because the facility processes more volume without expanding storage areas.

- Lower labor and transportation costs driven by fewer touchpoints and more efficient routing.

- A more predictable delivery rhythm that reduces delays and helps crews stay productive.

- Improved customer satisfaction and competitive advantage thanks to consistent, reliable material flow.

Together, these benefits help construction firms cut waste, keep sites under control, and maintain steady momentum in project delivery.

Risks and Constraints: When Cross-Docking Is Challenging

Cross docking becomes challenging under certain site and scheduling conditions. To understand where the method struggles most, consider the cases below:

- Limited site access, where narrow roads or restricted entry points prevent precise delivery timing.

- Unpredictable schedules, especially when design changes or shifting priorities alter the installation sequence.

- Heavy or oversized components that need special lifts or handling equipment, which slows the flow through the cross-dock.

- Dependence on multiple subcontractors, since shared delivery windows complicate coordination.

- Transport delays disrupt timing because materials do not stay in storage long enough to absorb schedule changes.

In these situations, cross docking software helps teams maintain visibility, adjust plans quickly, and reduce the impact of last-minute changes.

Always have the right materials on site

Track inventory in FirstBit ERP

Request a demo

Designing a Cross-Docking System for Construction

A cross-docking process works only when the physical layout, equipment, software, and scheduling operate as a single coordinated system. In construction logistics, this alignment becomes even more important because materials move quickly and site conditions change daily.

Facility Layout and Location

A construction cross-dock should sit between key suppliers and the project sites so travel times stay short and delivery cycles stay predictable. Inside the facility, materials need a direct path from receiving to dispatch. Simple I-shaped or U-shaped layouts help prevent cross-traffic and keep movement smooth.

A small staging area is still useful. It is not for storage but for quick sorting, sequencing, or checks before loading outbound trucks. This short buffer absorbs minor timing issues without slowing the overall flow.

Equipment, Material Handling and Automation

Equipment must match the size and weight of the materials moving through the cross-dock. Forklifts, telehandlers, cranes, pallet jacks, and conveyors should be selected based on the typical product mix, especially when dealing with structural steel, prefabricated elements, or bulky MEP assemblies. When the equipment is properly matched, loading and unloading stay consistent, and handling times stay predictable.

Automation helps with routine identification and repetitive movements. Sorters, barcode scanners, and RFID-enabled conveyors reduce manual errors and speed up basic tasks. Heavy or irregular items, however, still require manual or semi-manual handling, which means automation should support operators rather than replace them.

Cross Docking Software and Data Integration

Real-time data is essential because materials move through the cross-dock very quickly. Barcode or RFID scanning provides immediate identification, while cross-docking software assigns routing, timing, and outbound allocation.

When ERP or WMS systems integrate with supplier data and site schedules, everyone sees the same information. Forecasts, requests, and inbound plans stay aligned, which reduces misrouting and minimizes last-minute changes that could disrupt flow.

Scheduling, Assignment and Dock Management

Cross docking depends on precise timing. Inbound trucks must arrive within defined windows, and outbound trucks must leave when the site is prepared to receive the materials. If either side slips, congestion or idle time builds up quickly.

Structured dock assignments support this timing. Assigning doors by material type, project, or delivery priority keeps traffic organized and shortens loading cycles. Small buffer windows can absorb minor delays without turning the dock into a storage area, keeping the flow predictable.

Implementation Strategy & Best Practices for Cross-Docking

Cross docking becomes reliable only when the rollout is planned in stages, coordination is tight, and performance is measured against clear operational metrics. A structured implementation reduces risk and helps the system stabilize before it is scaled.

Phased Pilot Approach

A cross-docking model should be introduced gradually. Starting with a small pilot keeps the operation manageable and helps confirm that material flow, timing, and communication work as expected. Early pilots typically focus on low-risk or less time-sensitive materials so that any issues can be addressed without disrupting critical work. Once the process proves stable, teams can increase volume and add more material categories.

To-do list:

- Select 1–2 predictable materials for the initial pilot.

- Run the pilot with a limited number of suppliers and a single jobsite.

- Measure flow stability for two to four cycles before scaling.

- Expand only after confirming timing, labeling, and routing are consistent.

Stakeholder Coordination

Cross docking requires strong alignment across suppliers, carriers, and construction sites. Suppliers must commit to accurate labeling, proper packaging, and clear documentation so materials can move directly through the cross-dock. Carriers must follow scheduled windows and maintain reliability.

On the site side, receiving crews need clear procedures for unloading and confirming readiness, since late acceptance can cause immediate congestion.

To-do list:

- Set clear packaging and pre-sorting standards for all suppliers.

- Establish fixed delivery windows and require carriers to confirm arrival times.

- Train site teams on receiving procedures and readiness checks.

- Hold weekly coordination calls to review upcoming demand and delivery loads.

Metrics & KPIs

Cross docking relies on speed, accuracy, and flow stability, so tracking the right KPIs is essential. Throughput shows how much volume the dock can handle, and dwell time indicates how long materials remain inside the facility. Error rates, including misrouting or damage, highlight where processes need tightening.

On-time delivery to the site shows whether the operation is supporting actual installation schedules. Cost per handling event helps evaluate efficiency over time.

To-do list:

- Track throughput and dwell time daily.

- Record routing or scanning errors and investigate root causes.

- Measure on-time arrivals at the site and compare against the schedule.

- Review the cost per handling event monthly and benchmark improvements.

Risk Mitigation & Contingency Planning

Even well-run cross-docks face delays, design changes, and unexpected demand swings. A small buffer stock near the site or at the cross-dock provides short-term protection without turning into full warehousing. Flexible scheduling rules help absorb late trucks or shifting priorities.

Backup routing options, such as temporary storage yards or alternative carrier lanes, ensure the operation does not collapse during disruptions.

To-do list:

- Maintain minimal buffer stock for critical, high-risk materials.

- Keep flexible time windows for inbound trucks during peak periods.

- Pre-identify fallback yards or routing paths for emergency storage.

- Build a rapid response checklist for handling late deliveries or demand changes.

Maximize resource efficiency across every site with real-time tracking

Request a demo

Comparative View & Strategic Considerations

Selecting the right logistics model means understanding how the cross docking process differs from traditional warehousing and how each approach fits different project conditions.

Cross-Docking vs Traditional Warehousing in Construction

Cross docking works well when material demand is predictable and installation sequences are clear. It reduces site storage, cuts handling effort, and keeps deliveries aligned with daily schedules, which is the practical cross dock meaning in logistics for construction teams. Materials move quickly, so costs stay low, and delays are minimized.

Traditional warehousing is better when schedules shift often or when materials need long-term protection. It provides flexibility and buffering capacity, but at higher storage and handling costs. Most large projects use a mix of both, relying on cross dock shipping for predictable items and warehouses for uncertain or bulky stock.

Scalability & Multi-site Operations

Cross docking scales effectively when multiple sites share the same suppliers. A central hub can consolidate loads, reduce redundant transport, and support a steady outbound flow across several projects. This model suits regions where projects are clustered and follow similar material patterns.

When sites are spread out, smaller satellite cross-docks can reduce travel time and adapt more easily to local schedules. Centralized hubs offer efficiency and control, while decentralized locations improve responsiveness. The right structure depends on distance, supplier distribution, and how stable each site’s demand is.

Future Trends & Innovations

New technology is changing what cross docking is and how accurately it can operate. Predictive analytics and AI tools improve scheduling by matching inbound arrivals to installation needs, while cross docking software helps adjust plans in real time.

Automation is also expanding. Autonomous vehicles, drones, and robotic handling systems are emerging for short-range site movements. At the same time, modular construction increases the value of cross docking because prefabricated assemblies depend on fast, low-storage material flow.

How Firstbit ERP Streamlines Cross-Docking Process in Construction

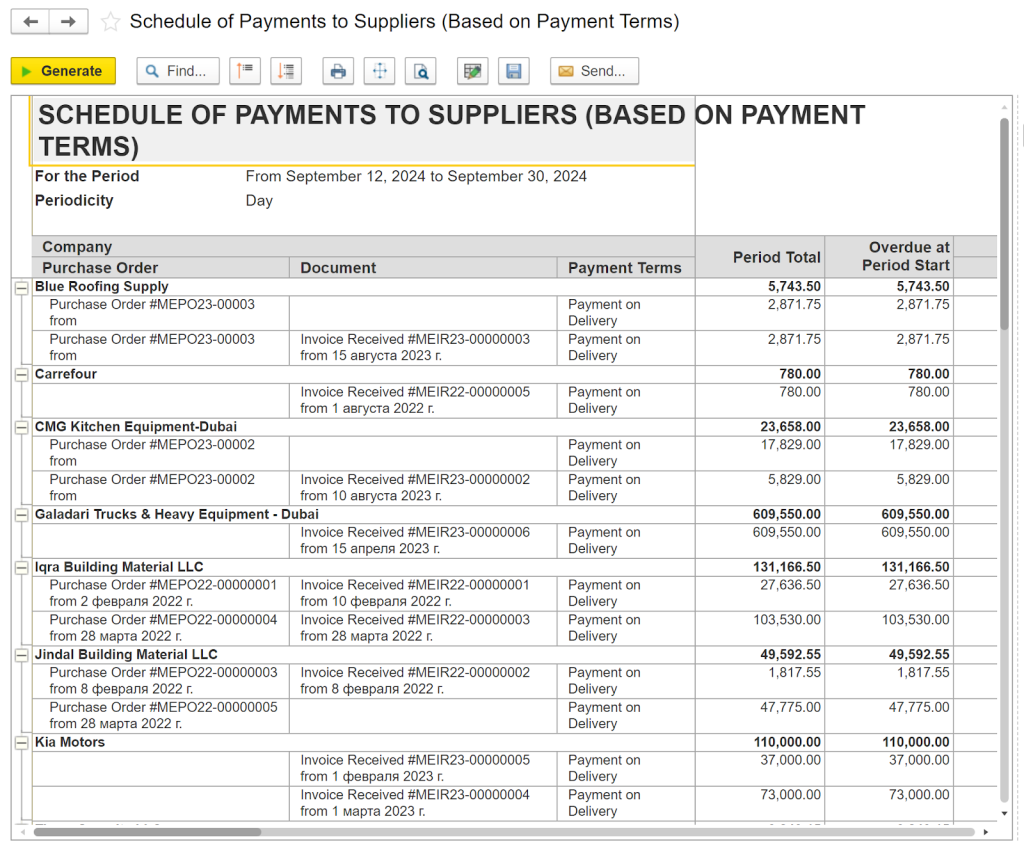

Cross docking depends on fast information flow, precise timing, and clean coordination between suppliers, the cross-dock, and the jobsite. FirstBit ERP supports this by giving teams a single, reliable source of data that keeps material movements synchronized and reduces the risk of delays.

- First, it aligns inbound and outbound schedules. When suppliers update shipment times or quantities, the system reflects those changes instantly. Site teams see the same information, so receiving plans stay realistic, and materials do not arrive before crews or equipment are ready.

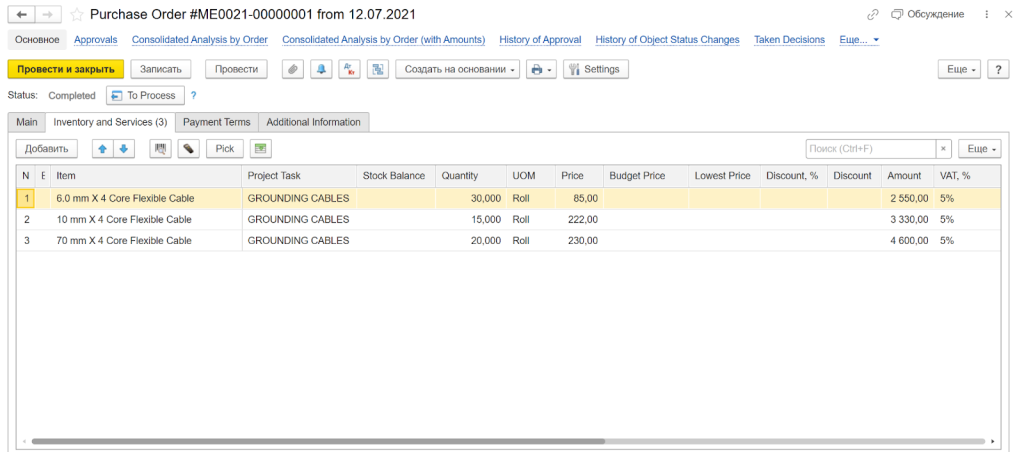

- Second, it links purchase orders, material requests, and delivery sequences. Cross docking is efficient only when every pallet is clearly identified and routed. FirstBit ERP connects procurement, warehouse handling, and site demand in one workflow, so the team always knows what each shipment is for and where it needs to go.

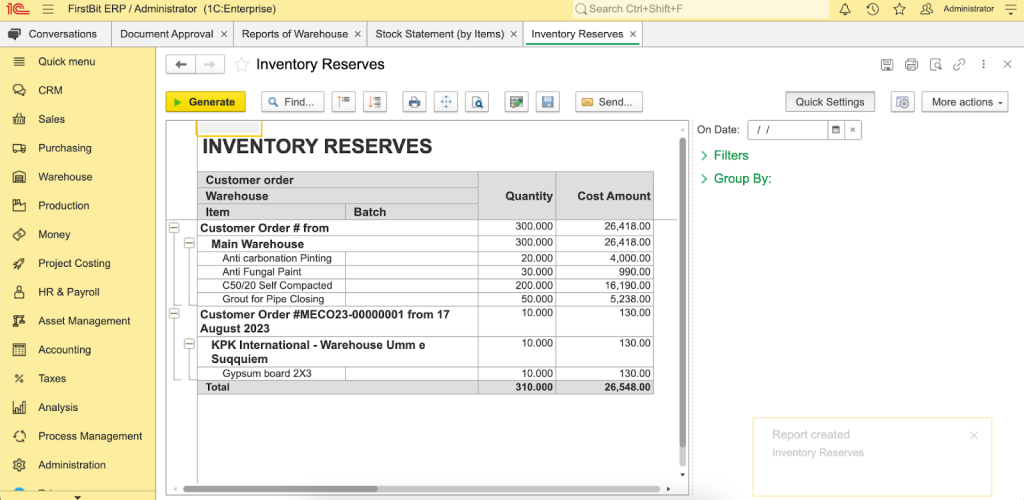

- Third, it provides real-time visibility for decision-making. Barcode scanning, material tracking, and automated confirmations let the cross-dock team react quickly when schedules shift or priorities change. The Inventory Reserves report in FirstBit ERP provides a clear view of available materials, their costs, and how they’re allocated across orders.

Together, these capabilities help contractors maintain a steady, installation-ready material stream, which is the core requirement for effective cross docking in construction.

Keep all supplies organized

Manage warehouses via FirstBit ERP

Request a demo

Conclusion

As construction projects grow in complexity and scale, the need for more efficient logistics becomes essential. Cross docking offers a strategic advantage in this context, streamlining material flow and reducing unnecessary delays. While it isn’t suitable for every situation, when implemented correctly, it can significantly enhance operational efficiency, particularly in large, time-sensitive projects.

The real key to success, however, lies in the integration of cross docking with advanced systems like ERP software, which ensures precision, accountability, and real-time coordination across all stages of the supply chain. For construction companies looking to stay ahead, adopting these practices is a necessity for long-term success.

F.A.Q.

Why is cross docking useful in UAE construction projects?

What types of construction materials are best suited for cross docking?

Is cross docking software necessary, or can I manage it with spreadsheets?

Can I use cross docking if my suppliers aren’t reliable?

Prevent shortages and costly delays

Request a demo

Anna Fischer

Construction Content Writer

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.