Delays in projects are not just about missing deadlines; they have a direct impact on costs, resources, and the project's overall success. When work is pushed back, expenses increase. Labor may need to stay on site longer, equipment rentals are extended, and site overheads continue without progress. At the same time, the project’s income is postponed, penalties may be applied, and cash flow can come under pressure.

Research shows that only 25% of construction projects are completed within 10% of their original schedule[?].

This means that delays are common, and without knowing the actual cost of each day lost, it becomes difficult to determine the best course of action. Understanding the cost of project delays helps teams make informed choices, set priorities, and protect profit margins.

What Is Cost of Delay in Project Management

The Cost of Delay (CoD) is a method for measuring the financial loss incurred when a project is delayed. It shows the value lost for every day, week, or month the project is late. This measure includes both direct and indirect effects of a delay.

Direct effects include additional labor and supervision, longer equipment hire, higher material costs resulting from price changes, and storage fees. Indirect effects include delays in earning revenue, losing a

competitive advantage, or damaging relationships with clients and stakeholders.

Knowing the CoD allows project managers to make decisions based on numbers rather than guesswork. If the daily cost of a delay exceeds the cost of adding resources to speed up work, it makes financial sense to accelerate. If the financial impact is small, resources can be focused on higher-priority activities. CoD turns delay management into a planned and measurable process instead of a reactive one.

Cost of Project Delays: Types

Not all delays affect a project in the same way. Two projects may face the same amount of time lost, but the financial consequences can be completely different. The cost of delay depends on factors such as contractual commitments, market timing, revenue potential, and the strategic importance of the project. By understanding the type of delay, project managers can decide where to allocate resources, how quickly to respond, and which mitigation strategy will deliver the greatest value.

Standard Cost of Delay

This is the most straightforward type. The cost increases at a steady, predictable rate for every day, week, or month the project is delayed. Each time period of delay results in the same amount of loss.

For example, consider a hotel project that is expected to generate AED 500,000 in monthly revenue once it opens. If completion is delayed by two months, the total loss is AED 1 million in revenue, regardless of when the delay happens. This same principle applies to industrial facilities, rental properties, or infrastructure projects where income or operational savings start only after completion.

Because the loss is constant, standard CoD is the easiest to calculate and plan for. It allows decision-makers to directly compare the cost of speeding up work (e.g., adding another shift) against the cost of leaving the delay unresolved.

Fixed Date Cost of Delay

With a fixed date CoD, the financial impact remains minimal until a specific deadline is missed. Once that date passes, the cost rises sharply, sometimes so high that the opportunity is lost entirely.

This is common in situations like:

-

A retail store is scheduled to open before the holiday shopping season. Missing the launch date means losing peak seasonal sales that cannot be recovered later.

-

A government infrastructure project that must meet a regulatory compliance date to avoid large fines or funding withdrawal.

-

A stadium construction project is linked to a major event, such as a tournament or concert.

In these cases, meeting the deadline is critical. Even if delays earlier in the schedule seem small, if they threaten the final date, urgent corrective measures are required. Buffer time, frequent progress reviews, and early escalation of risks are key to managing this type.

Urgent Cost of Delay

An urgent CoD has the opposite pattern to a fixed date delay. Here, the financial loss is highest at the start of the delay and gradually decreases over time.

This is often seen in:

-

Highly competitive markets where being first to launch offers a major advantage, such as releasing a new property in a growing commercial district or introducing an innovative product to market.

-

Safety or compliance projects where early completion avoids ongoing fines or legal risks.

-

Contract work where early delivery earns significant incentives, but those incentives reduce over time.

For example, if a tech company plans to launch a new product ahead of competitors, each day of delay before launch could lead to lost market share and reduced long-term sales. Once competitors have caught up, the financial impact of further delay may be less severe. The key to managing urgent CoD is rapid mobilization and quick decision-making in the early stages of the project.

Intangible Cost of Delay

Some delays have little measurable short-term financial impact but can cause indirect or long-term issues. These are called Intangible CoDs.

Examples include:

-

Minor architectural enhancements that improve the end-user experience but are not essential for operational launch.

-

Cosmetic upgrades to a completed facility, such as landscaping or non-essential design elements.

-

Internal process improvements that don’t affect current project delivery but could enhance future efficiency.

While these delays might not affect immediate revenue, leaving them unresolved for too long can lead to dissatisfaction among clients or end-users, affect brand reputation, or create additional work later. It is important to track these items and address them at the right time, without letting them disrupt higher-priority work.

Stay ahead of delays

Monitor project progress with FirstBit

Request a demo

Causes of Delay and Cost Overruns in Construction Projects

Delays and

cost overruns are rarely the result of a single mistake. They typically develop from recurring operational or management weaknesses that compound over time. Identifying these factors early enables project leaders to take targeted action, protecting both schedule and budget.

A review by Morris and Hough (1987), covering about 3,500 projects, found that overruns are the norm and generally range between 40% and 200% (Reichelt & Lyneis, 1999). Furthermore, a study by Flyvbjerg et al. (2003a) found that 86% of projects experience cost overruns, with an average overrun of 28%[?].

This level of overrun shows just how common and costly

project delays can be. Each cause, whether tied to material supply, scheduling accuracy, or on-site incidents, can create a ripple effect that drives up costs, disrupts workflows, and pushes completion further out.

Supply Chain Disruptions

A construction project is dependent on a steady flow of materials, equipment, and components. When that flow is interrupted by manufacturing delays, transport bottlenecks, customs holdups, or supplier insolvency, the work sequence is broken. Critical-path activities may be stalled for days or weeks, leading to idle labor, wasted equipment hire, and rushed sequencing that can compromise quality.

For example, a delay in delivering prefabricated façade panels can stop not only exterior finishing but also interior fit-out, since many internal works require the building to be weather-tight. The result is a cascading delay across multiple trades.

Mitigation starts with early identification and procurement of long-lead items, having multiple suppliers where possible, staging deliveries to match the schedule, and using digital tracking systems that alert teams immediately if shipments deviate from their planned arrival date.

Lack of Real-Time Reporting

Decisions are only as good as the information available at the time they are made. In many projects, reporting is periodic—weekly or monthly—which means emerging problems can go unnoticed until they are already affecting the schedule.

For instance, a drop in concrete pour productivity or delays in MEP rough-in inspections may not be flagged until a formal report is issued, by which point recovery options are limited and costly. Without real-time visibility, management reacts to problems rather than preventing them.

Implementing live dashboards linked to site diaries, inspection records, procurement updates, and labor tracking allows managers to see deviations immediately. This enables early interventions, such as reallocating crews, accelerating approvals, or resequencing work to protect the project’s critical path.

No Process Standardization

When subcontractors or internal teams operate with different methods and quality standards, the project loses consistency. The result is rework, inspection failures, and misaligned workflows, all of which extend timelines and inflate costs.

For example, if one subcontractor uses different installation tolerances from the rest, completed work may fail inspection, forcing reinstallation and delaying subsequent trades. Beyond direct costs, rework also affects morale and productivity.

The solution lies in clear, enforced process standards: approved method statements, Standard Operating Procedures (SOPs), Inspection and Test Plans (ITP), and mandatory pre-task briefings. Regular quality audits and first-off inspections ensure that deviations are caught early and corrected before they become major issues.

Inaccurate Scheduling and Forecasting

A schedule that looks good on paper but is not grounded in realistic data will almost always fail during execution. Common causes include underestimating task durations, ignoring supplier lead times, failing to integrate weather or site access constraints, and not allowing contingency for approvals.

These errors often lead to crews arriving before materials, equipment sitting idle, or multiple trades crowding the same space, reducing productivity and increasing safety risks. Over time, these inefficiencies snowball into significant delays and cost overruns.

Robust scheduling uses historical productivity data, supplier input, and resource-levelled plans that match actual crew and equipment availability. Maintaining rolling three- to six-week look-ahead schedules updated weekly helps spot risks early and adjust sequencing before they affect critical milestones.

Theft or Injury

Security breaches and workplace accidents can instantly stop work. Theft of high-value equipment or bulk materials leads to replacement delays, insurance claims, and, in some cases, redesign if the stolen components are no longer available. Injuries often result in mandatory stop-work orders, investigations, and reduced productivity even after work resumes.

These incidents have a dual impact: direct financial loss and disruption to the schedule. For example, a crane theft or damage can halt major lifting operations, affecting multiple downstream tasks. Similarly, a serious injury in a key area of the site may require cordoning off that zone, delaying several work packages.

Prevention requires layered security access control, CCTV monitoring, asset tagging, and regular tool checks, as well as a proactive safety culture. Daily safety briefings, task-specific risk assessments, and rigorous enforcement of safe work procedures significantly reduce the likelihood of incidents.

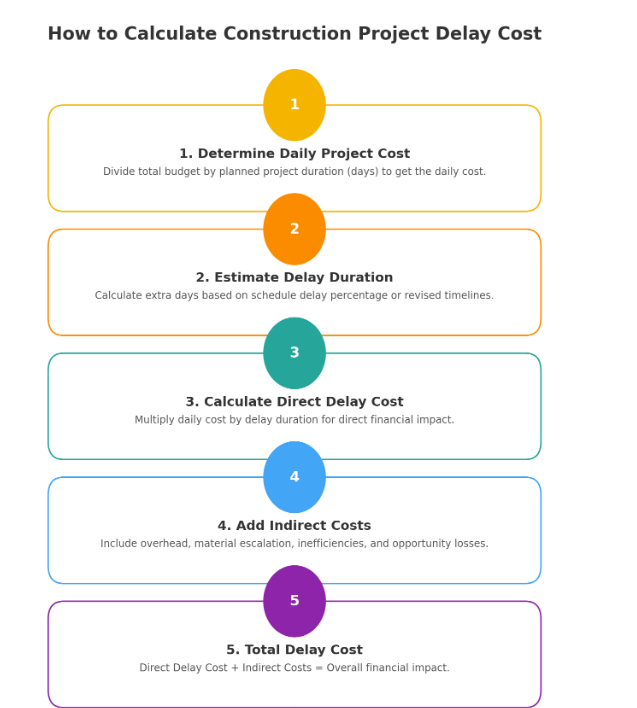

How to Calculate Construction Project Delay Cost

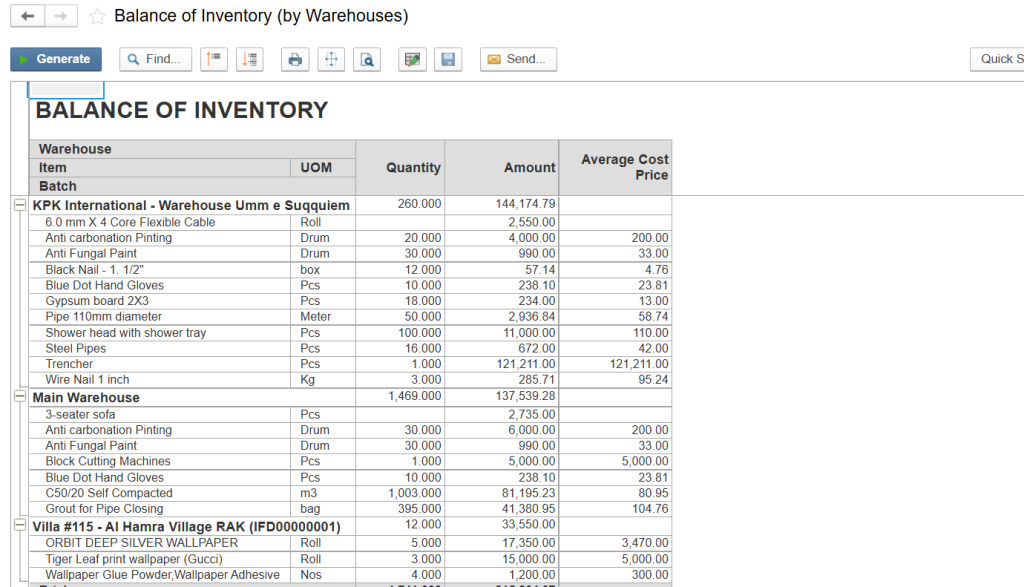

Steps to calculate Construction Project Delay Cost

Calculating the financial impact of a delay requires more than just multiplying a daily rate by the number of lost days. A thorough calculation considers both direct costs (losses directly tied to the delay) and indirect costs (knock-on effects such as reduced efficiency or material price escalation). By breaking the process into structured steps, project teams can quantify the impact accurately and make informed decisions about mitigation.

Step 1: Determine the Daily Cost of the Project

The first step is to establish the project’s daily cost based on its total value and planned duration. This includes all budgeted expenses such as labor, equipment, subcontractor payments, and overhead, spread evenly across the project timeline.

Example:

A project valued at $50 million with a planned duration of 36 months (1,095 days) has an average daily cost of:

$50,000,000 ÷ 1,095 days = $45,662 per day

While this is a simplified figure, it provides a baseline for understanding the financial exposure per day of delay.

Step 2: Estimate the Delay Duration

Next, calculate how long the delay is expected to last. This can be based on revised schedules, current productivity rates, or specific known issues (e.g., late delivery of long-lead materials).

Example:

If the project is facing a 30% delay on its original 3-year schedule, the delay duration would be:

1,095 days × 0.30 = 329 days (rounded to 330)

This step is critical because underestimating the delay period leads to an incomplete cost assessment.

Step 3: Calculate the Direct Cost of Delay

Multiply the daily cost by the delay duration to determine the direct financial impact. This covers the costs of labor, equipment, and other site resources remaining engaged beyond the planned completion date.

Example:

$45,662 × 330 days = $15,068,460

This figure represents the direct cost of extending the project without considering indirect impacts.

Step 4: Add Indirect and Escalation Costs

Indirect costs are often significant and can add 20–30% or more to the direct delay cost. These may include:

-

Administrative and management overheads. Continued salaries for project management, engineering, and support staff.

-

Material price escalation. Increased costs for materials purchased later than planned due to inflation or market volatility.

-

Labor inefficiency. Reduced productivity as crews work out of sequence or in congested spaces.

-

Opportunity costs. Lost revenue from delayed operational use of the asset.

Example:

Assuming a 25% indirect cost factor:

$15,068,460 × 0.25 = $3,767,115

Total Estimated Delay Cost:

$15,068,460 + $3,767,115 = $18,835,575

By using this structured approach, project teams can present a transparent and defensible estimate of the financial impact of delays. This not only helps in claims and negotiations but also guides decisions on whether acceleration measures are cost-effective compared to the cost of inaction.

Keep your project on track

Request a demo

Formula to Calculate the Cost of Project Delays

The total financial impact of a delay in a construction project can be estimated with this formula:

Total Delay Cost = (Daily Project Cost×Delay Duration) + Indirect Costs

This formula works by first determining how much the project costs to run per day, multiplying that by the number of delayed days, and then adding the secondary costs that delays cause, such as material price increases or extended overhead expenses.

1. Daily Project Cost

This figure represents the average amount your project spends per day to stay operational. It includes wages, subcontractor fees, equipment rentals, utilities, and site overhead.

Daily Project Cost = Total Project Budget ÷ Planned Duration (days)

If your project budget is high or your schedule is short, the daily cost will be significant, meaning even small delays can quickly add up to substantial losses.

2. Delay Duration

This is the total number of extra days the project runs beyond the original schedule. It’s calculated by multiplying the planned schedule length by the percentage of delay.

Delay Duration = Planned Duration × Delay Percentage

For example, a project planned for three years with a 30% delay will face nearly a full year of extra work, each day incurring additional cost.

3. Indirect Costs

Delays don’t just extend the direct costs; they create ripple effects. These include:

-

Material price escalation due to market changes

-

Reduced productivity from workforce fatigue or demotivation

-

Extended equipment rentals and site maintenance

-

Administrative overhead for prolonged management and supervision

These indirect costs are typically estimated as a percentage of the direct delay cost, with industry benchmarks often in the 20–30% range.

Example Calculation

Let’s walk through an example step-by-step so the formula is easier to apply in real situations:

- Total Project Budget: $50,000,000

- Planned Duration: 1,095 days (3 years)

- Daily Project Cost: 50,000,000 ÷ 1,095 = $45,662/day

- Delay Duration: 1,095 × 0.30 = 330 days

- Direct Delay Cost: 45,662 × 330 = $15,068,460

- Indirect Costs (25%): 15,068,460 × 0.25 = $3,767,115

- Total Delay Cost: 15,068,460 + 3,767,115 = $18,835,575

By using this formula, project managers can assign a tangible cost to every day of delay. This makes it easier to justify acceleration measures, negotiate claims, or decide whether to proceed with a change that might extend the schedule.

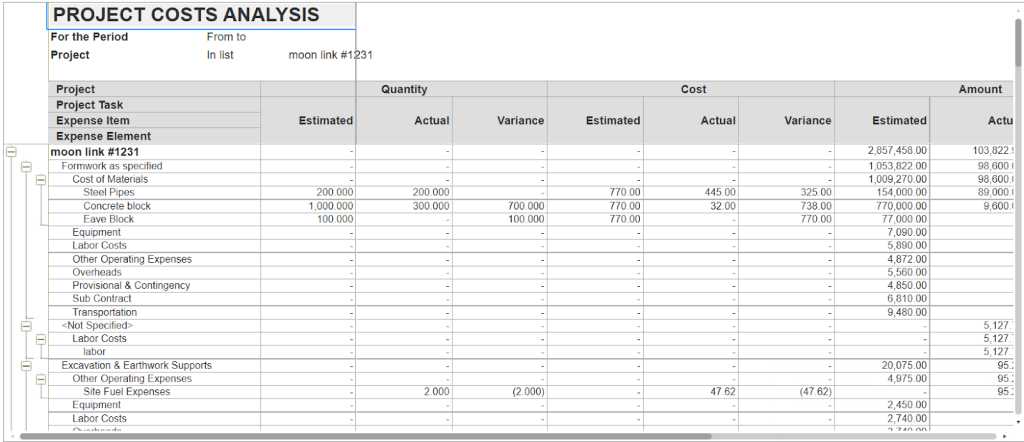

Minimize Project Delays With FirstBit ERP

The most effective way to deal with delay costs is to prevent them from occurring in the first place. This is where a construction-focused ERP like FirstBit proves invaluable. Instead of relying on fragmented spreadsheets, manual updates, and reactive management, FirstBit provides a unified platform for real-time project control.

One of its biggest strengths lies in live cost tracking. Project managers can upload BOQs, allocate materials and labor budgets, and instantly compare planned vs. actual spending. This visibility allows them to catch cost overruns before they spiral into full-blown budget crises.

Project cost analysis in FirstBit ERP

Schedule management is equally robust. With integrated Gantt charts, progress dashboards, and

earned value analysis, FirstBit allows teams to spot early warning signs of slippage. For example, if a subcontractor is falling behind or a material shipment is delayed, the system flags the risk immediately, giving teams time to take corrective action rather than waiting for the problem to surface later.

Material availability is another common cause of construction delays. FirstBit’s procurement and inventory modules keep requisitions, purchase orders, stock levels, and supplier performance fully synchronized. This reduces the likelihood of material shortages or last-minute sourcing at inflated prices.

Inventory in FirstBit ERP

Finally, automated alerts and approval workflows ensure that decision-making is both fast and documented. Instead of delays caused by waiting for manual sign-offs or chasing missing information, all stakeholders can see pending approvals, access project data, and collaborate in one place.

By centralizing cost, schedule, procurement, and communication in a single, integrated platform, FirstBit ERP helps construction companies move from reactive problem-solving to proactive risk prevention, minimizing the time and money lost to avoidable delays.

Boost project performance

Assign the right people to the right tasks

Request a demo

Conclusion

Delays in construction projects are inevitable to some degree, but the size of their impact is not. The difference between a manageable setback and a multimillion-dollar loss often comes down to preparation, visibility, and control.

Having a proven calculation method ensures that any delay is understood in financial terms from the outset, allowing decision-makers to evaluate options logically rather than emotionally. More importantly, equipping teams with the right tools, such as a comprehensive ERP system, transforms project management from a firefighting exercise into a process of continuous oversight and timely intervention.

Ultimately, controlling the cost of delays isn’t just about safeguarding profit margins. It’s about delivering on commitments, protecting relationships with clients, and maintaining the credibility that keeps a construction business competitive in a demanding market.

FAQ

What is the average cost of delay in construction projects?

It varies by project, but research shows a one-week delay can raise costs by 5–10% due to extended labor, equipment rental, penalties, and indirect losses.

Can software help track the financial impact of delays?

Yes. Modern ERP systems provide real-time tracking of tasks, resources, and contracts, automatically calculating overrun costs and comparing planned vs actual timelines.

How to calculate the delay cost in construction project management?

Common methods include Time Impact Analysis (TIA), as-planned vs as-built comparison, and daily cost tracking. Digital tools can automate these calculations for accuracy.

Is delay always the contractor’s fault?

No. Causes range from weather and supply chain issues to design changes and permit delays. Responsibility must be proven to assign costs fairly.

Stay ahead of schedule

Request a demo

Umme Aimon Shabbir

Editor at First Bit

Aimon brings a deep understanding of the modern construction business to her articles by providing practical content.