In 2025, construction labor costs are expected to continue rising, with wages projected to increase by approximately 4-5% per year.[?]

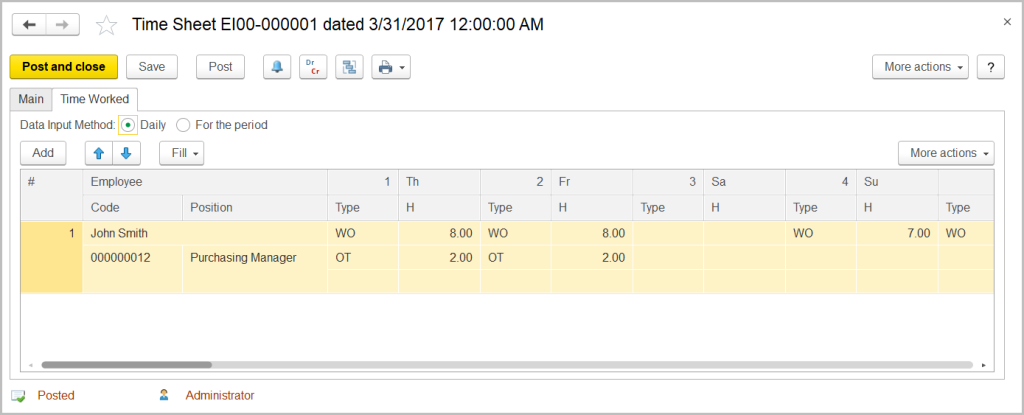

What Is Time Sheet in Construction?

-

How. The number of hours workers put in

-

What. The tasks they performed

-

Where. Which job or site they worked on

Example: Imagine a foreman marking down that twelve workers were on-site, when in reality only nine were present. That three-person difference could translate to hundreds of unearned labor hours over the course of a month. This will skew payroll and inflate project costs.

Formats of Construction Time Sheets

-

Paper logs. In this manual method, workers physically sign in and out each day. This strategy for tracking hours remains common on smaller sites or for short-term projects. That being said, paper is still easy to lose, vulnerable to the elements, and prone to “buddy punching,”[?] where one worker signs in for another.

-

Manual spreadsheets. Spreadsheets are typically considered the “step up” from paper. They allow HR or finance teams to collect information in a structured way. However, this method depends heavily on manual data entry, which creates bottlenecks and increases the risk of formula or typing mistakes.

-

Supervisor reports. Site managers prepare daily reports that combine hours worked with notes on productivity, safety, and incidents. While more informative than regular paper logs, these documents lack standardization and vary in content depending on who fills them out.

-

Digital timesheets. The advanced solution is a cloud-based, mobile, or ERP-integrated system that automates data entry, adds GPS verification, and connects directly to payroll. These types of tools reduce admin work, increase accuracy, and simplify compliance reporting.

Poor productivity has cost U.S. contractors as much as $40 billion in a single year.[?]

Purpose of Time Sheets

-

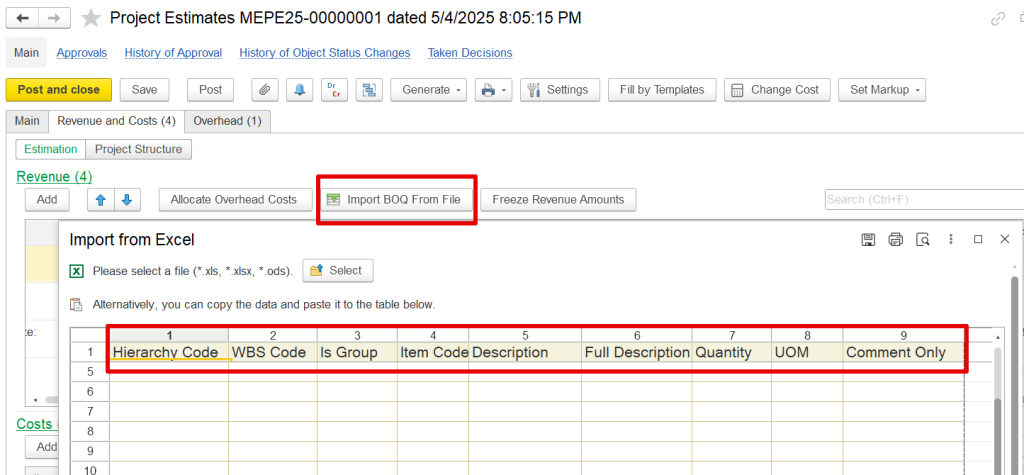

Monitor labor costs. Time sheets directly tie hours to a Bill of Quantities (BOQ) and cost codes, providing contractors with visibility into whether their time tracking is above or below budget.

-

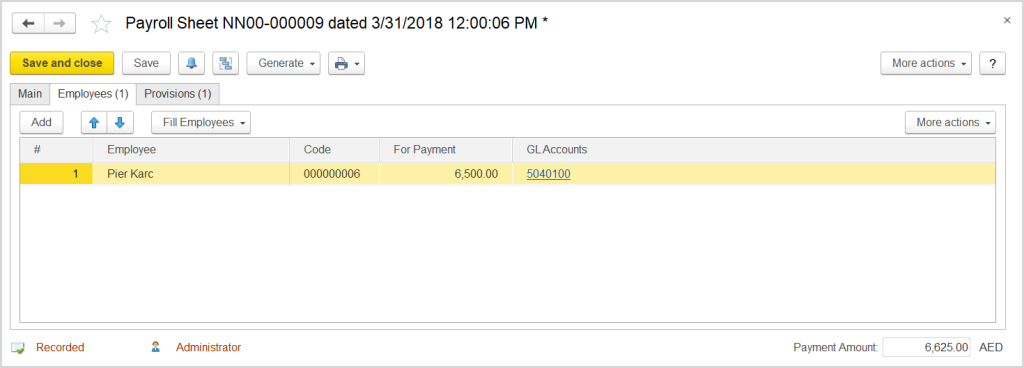

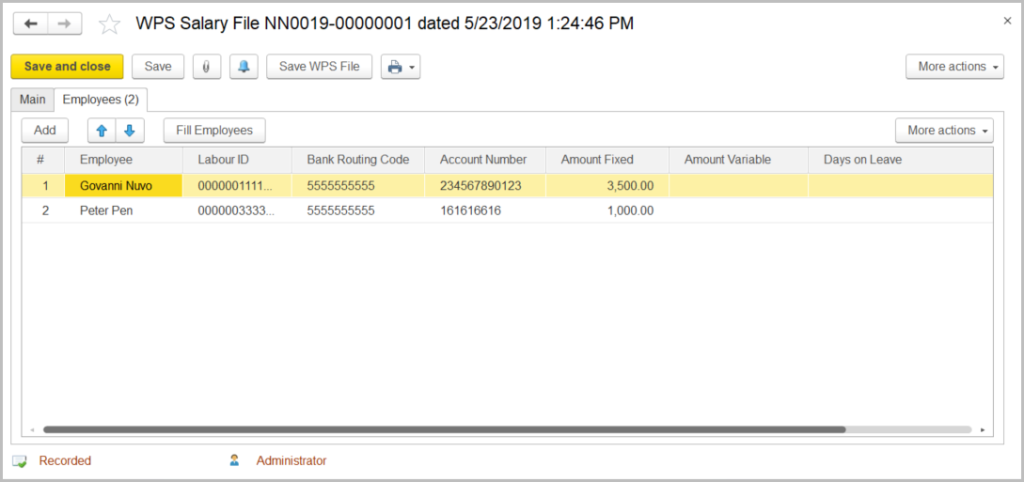

Ensure compliance. Many jurisdictions require proof of hours worked to ensure compliance with labor laws. For example, WPS payroll demands precise records of wages and hours.

-

Improve accountability. Time sheets are a neutral, verifiable record of who worked, what was done, and when. This reduces disputes between employers, subcontractors, and clients, while giving employees confidence they’ll be fairly paid.

70% of contractors struggle to meet deadlines due to labor shortages. This has caused firms to ask skilled workers to take on more tasks and has increased costs for new projects.[?]

Why Using a Timesheet in Construction Is Important

-

Accurate tracking of labor. Timesheets answer the “who,” “when,” and “where.” This prevents ghost workers and inflated hours.

-

Cost monitoring. By linking hours to budgets and BOQs, labor costs can better align with planned work.

-

Compliance. In the UAE, payroll systems require proof of hours worked. The UAE Labour Law limits standard working hours to 8 per day (48 per week), and overtime is compensated accordingly. Without accurate records, a company can’t verify its legal compliance.

-

Transparency. Using time sheet tracking, employees see fair pay, clients see better billing, and supervisors see who is pulling their weight.

Pro Tip: Time sheets = evidence + accountability + compliance + financial control.

Track attendance and pay only for actual work hours

Benefits of Construction Time Sheets for Different Stakeholders

-

Contractors and employers. Gain visibility into labor distribution and prevent overruns. They can also allocate staff more effectively across different sites.

-

Subcontractors. Time sheets help to avoid underpayment and ensure jobs are correctly logged, protecting revenue.

-

Site managers and supervisors. It gives them data for planning a tight schedule, adjusting shifts, and forecasting completion dates.

-

Employees and fieldworkers. Workers can gain peace of mind knowing their pay reflects actual effort, which also reduces conflict.

-

Clients. Clients always receive detailed documentation of hours and tasks, which reinforces brand trust.

Disputes over hours are among the top three causes of subcontractor payment delays. Proper timesheet use reduces these disputes by over 40%.[?]

Paper vs. Digital Timesheets in Construction

Challenges of Paper and Manual Methods

-

Bad handwriting. It can be unclear, leaving payroll staff to interpret what workers meant.

-

Missing or incomplete sign-in entries. They lead to disputes and payment processing delays.

-

Durability. Paper sheets can be lost, get wet, or be damaged on active sites, where the weather poses a constant challenge.

-

Manual entry. Even intact records must be manually entered into payroll, which is both slow and prone to errors.

-

Fraud. “Buddy punching” is common with paper logs. On larger projects, this can translate into hundreds of false hours and wasted payroll dollars. It also means fewer people are actually working the site, which can lead to safety issues.

Advantages of Digital Timesheets

A report by the APA found that automating payroll processes can reduce errors by as much as 80%.[?]

Common Challenges with Time Sheets in Construction

-

Missed or forgotten entries. Crews often move between tasks or sites. If someone forgets to clock in or out, it creates gaps that must be manually reconciled, leading to ambiguity and additional rework.

-

Lack of real-time visibility. When timesheet data is submitted weekly or after the fact, project managers lose the ability to respond dynamically to issues, such as overtime overruns or labor shortages.

-

Inaccurate entries. Workers may increase their hours. Automated tools can prevent that with validation prompts. For example, an ERP system like FirstBit can show a warning when someone tries to submit time that doesn’t seem plausible.

-

Multiple job sites and decentralization. With crews operating in different locations, coordinating and consolidating time data can become complicated. Some sites may lack connectivity, while others may have workers using disparate systems or none at all.

-

Poor integration with payroll or accounting systems. Timesheet systems that are not directly integrated with payroll or project accounting require manual data transfers, re-entry, and reconciliation. This increases the risk of errors and delays.

-

Compliance and regulation risks. Construction firms must adhere to complex labor laws, including regulations on overtime, break periods, prevailing wages, and worker classification. Inaccurate timesheets can result in noncompliance, fines, or legal liabilities.

-

Resistance to technology or user adoption. Even when digital timesheet tools are available, field crews may resist adopting them. Among reasons are unfamiliar interfaces, lack of mobile friendliness, language barriers, or connectivity issues.

Best Practices for Managing Time Sheets in Construction

-

Daily updates. Log hours every day and avoid relying on memory.

-

Regular reviews and approvals. Supervisors/managers should review and approve time sheets every week to prevent payroll bottlenecks.

-

Define clear policies and standards. Document when and how workers should clock in and out, how breaks are managed, rules for overtime, and the approval workflow.

-

Allow offline and mobile access. Job sites often have poor connectivity. Ensure your system can function offline by caching clock-in and clock-out data, then sync when back online.

-

Integrate with payroll, accounting, and project management systems. Seamless integration eliminates duplicate data entry and reduces errors. It ensures that time data flows accurately into cost reports, payroll, and performance dashboards.

-

Adopt industry-specific digital tools. Use time tracking software designed for construction workflows. These tools often include cost-code allocation and offline capabilities—features that generic time-tracking systems typically lack.

-

Use automation. Systems like FirstBit ERP help automate validation, track progress for each BOQ line, and reduce manual tasks.

-

Use role-based permissions and locking mechanisms. Limit who can edit, approve, or alter time sheets. Once a period is approved, lock the records to prevent backdating or unauthorized edits.

-

Train field teams and supervisors continuously. Provide clear, hands-on training so all users understand how to use the system correctly. Explain why time accuracy matters and how errors should be corrected. Refresh training periodically.

-

Compliance checks. Ensure systems match the regional labor laws to prevent hefty fines.

Pro Tip: Pair timesheets with equipment logs. Tracking labor and equipment together produces a more accurate picture of site productivity.

Manage schedules in real time with FirstBit

Why Contractors Choose FirstBit ERP for Timesheet Management

Features that Support Timesheet Management

-

Digital time sheets. Mobile-based, real-time entry that will eliminate delays and errors.

-

Cost allocation. FirstBit ERP links hours to BOQs, further ensuring budget accuracy.

-

Automated payroll. Timesheets are fed directly into payroll, reducing administrative hours and creating a paperless construction site.

-

Compliance management. Built-in support for regional laws, WPS, and certified payroll.

Pro Tip: Integrating timesheets with FirstBit will enhance project forecasting, enabling managers to adjust manpower before issues escalate.

Conclusion

FAQ

See FirstBit ERP solutions in action

After the demo you will get a quotation for your company.