Following the economic recession during the 2020 pandemic, few anticipated an upswing in construction technology trends — an innovation that had been impending for years. The demand for emerging construction technologies is mainly driven by sustainability, efficiency, and safer working environments.

As we move into 2026, technologies like 5-D modeling, robotics, and the Internet of Things (IoT) are past their trial runs and ready to revolutionize the construction sector. Based on the current trajectory, the global construction industry is expected to double within the current decade, reaching $14.4 trillion.[?]

With the promise of a booming market, construction firms are seizing the opportunity to not only meet the escalating demand for infrastructure but also to address long-standing inefficiencies. Read on for our list of the top game-changing technologies that are set to rule the construction industry in 2026.

Top Construction Technologies 2026

Whether you’re aiming for sustainable living, reducing inefficacies in planning and modeling, or establishing safer work conditions, staying on course with the latest developments is pivotal for any business — a bit more so for construction enterprises. From advanced techniques to sustainable practices, we’ve outlined the eight most innovative technologies in the construction industry for the upcoming year.

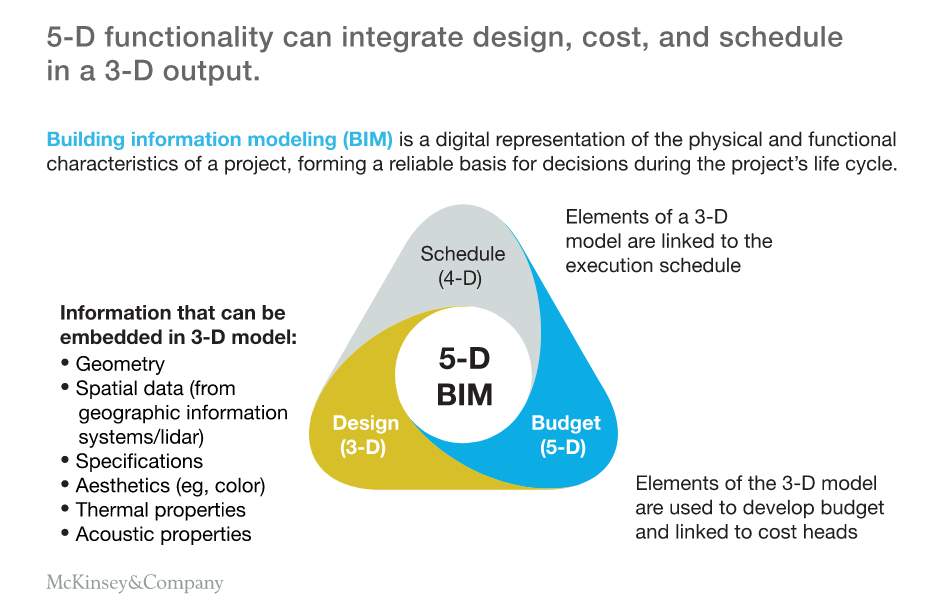

5D Building Information Modeling (BIM)

Early architectural designs were nothing but a hodgepodge of blueprints and chart papers, requiring input from all stakeholders involved. The process of clients and architects discussing aesthetics, making last-minute changes, and then relaying it to engineers left too much of a communication gap and inefficiency.

Unlike the traditional route, where builders couldn’t weigh in on constructability and budget scheduling, 5D Building Information Modeling (BIM) fills the void quite seamlessly.

5D BIM sets a virtual setting where stakeholders collaborate to develop parametric building components of their projects in real time. A step ahead of the 3D design model, 5D BIM also integrates budget and scheduling elements.

Instead of working in isolation, 5D BIM creates a cohesive environment where everyone can propose and demonstrate changes to layouts, project budgeting, and schedules. It’s akin to a construction ERP software that streamlines project management. No more ‘what ifs’ or unwanted surprises, as the project takes shape.

Make fast, data-driven decisions with real-time dashboards

Request a demo

Digital Twin Technology

What are the odds of hitting dead ends or facing unexpected delays when you have a digital doppelganger of your project to work with? Virtually none, right? A digital twin is a digital representation or simulation of a real-world object, or in this case, a construction project.

The simulation allows architects and engineers to gain a deeper understanding of the project’s design, intended functionality, and potential bottlenecks before breaking ground. A 3D replica of a facility under construction serves perfectly for beta-testing using minimum human and capital resources. Digital twins enable:

-

Streamlined collaboration between project stakeholders

-

Early detection and rectification of crucial design flaws

-

Pinpointing high-risk areas and communicating them to relevant departments

-

Efficient workflows between architects and contractors

-

Automated progress monitoring from start to end

The digital twin technology relies on 3D laser scanners, drones, and IoT-enabled machines to image a structure or building. When integrated with AI and Machine Learning, a digital twin keeps in line with the latest developments and self-updates to mirror the adjustments made to its real-world counterpart.

What makes it truly ground-breaking is the scale. Digital twin tech isn’t limited to a single structure or building, it can image entire townships.

In 2022, Las Vegas unveiled a digital twin of a 7-square-kilometer downtown area to predict future scenarios and prioritize actions that best address them.[?]

Construction Robotics

Seeing actual robots at construction sites laying brick walls, setting pavements, or assembling scaffolding trusses is no longer a scene from a sci-fi flick. Slowly but steadily, robots are making their way into the construction industry. You may have already witnessed robotic heat welders and remote-controlled demolition robots being used at construction sites. 2026 is set to take it one step further.

The global construction robotics market was valued at $1,028.6 million in 2022, spurred on by growth during the COVID-19 pandemic. It is expected to rise at an annual growth rate CAGR of 17.5%.[?]

While it has led to a 10% employment loss, robots will not replace human labor entirely, at least not in the near future. Rather, these robots are designed to work alongside manual workers to boost productivity and make construction processes safer and easier.

Automated construction ensures much greater precision and accuracy in construction operations, saving time, money, and reducing waste. Here are the types of robots being used in the construction department:

-

Bricklaying robots. These are not full-fledged robots but are known as semi-automated masonry (SAM) systems. They are designed to assist masons with all the strenuous work like lifting bricks, applying mortar, and setting bricks in place. SAM helps reduce labor costs, boost productivity, and limit churn rate.

-

Construction layouts. When it comes to precision and accuracy, machines always have the upper hand. Instead of manually marking floors according to architectural settings, a construction layout robot physically prints layout plans onto the site using CAD drawings or BIM models.

-

Demolition robots. In the construction sector, demolition is equally important. Compared to manual labor, demolition robots, like concrete sawing and remote-operated crushers, offer a faster, safer, and cheaper route to demolishing a building down to rubble.

-

Jobsite monitoring robots. Equipped with advanced technologies like LiDAR and AI, these robots use autonomous drones and rovers to assess the real-time progress of a construction site. They then use AI to compare those scans with BIM models and CAD drawings to inspect the quality of the work performed.

Transform your business

Embrace innovation with FirstBit ERP

Request a demo

Virtual and Augmented Reality (VR/AR)

There is more to AR/VR than just films and gaming. This technology is slowly creeping into the construction sector, opening up new ways of collaboration, planning and visualizing design renderings, and worker training. Current estimates project that AR/VR technologies could cut building costs by up to 90%, mostly by eliminating human errors and inaccuracies.[?]

Virtual Reality and Augmented Reality, though often related, bring different functionalities to the table. While VR creates a virtual replica of a construction project that visualizes design aesthetics, AR helps architects view 3D models of buildings within the actual construction site. It enables developers to visualize how a particular installation would appear in reality. But their use case is not just limited to on-site workers.

VR/AR applications support connected construction sites, where workers can participate in in-house meetings and share and access information in real-time. Many construction firms hold virtual training sessions for workers via VR ahead of complex jobs.

UAVs and Drones

While adoption is still in the early stages, unmanned aerial vehicles (UAVs) and drones are set to revolutionize the construction sector in the future. From initial site surveying and mapping to real-time monitoring construction projects, drone surveillance ensures your project is executed as planned. Here’s how engineers are utilizing UAV technology to simplify construction mechanics.

Pre-construction Site Surveys

Every venture begins with architectural layouts, which are often dependent on comprehensive site surveys and topographic maps. Relying solely on manual labor to assess the terrain can be time-consuming and expensive, not to mention the imprecise calculations.

Since drones are equipped with LiDAR sensors, they can survey large construction sites, and capture detailed imagery and topographical data, which forms the basis for 5D modeling.

Construction Inspection

When building large structures and high-rises, manual inspection and fieldwork become challenging.To reduce the duration of these tasks, contractors often designate field crews, though this approach can significantly impact the budget.

UAVs, in comparison, offer a cost-effective and efficient way to monitor construction sites. These drones provide a bird’s-eye view of the under-construction facility, giving managers a clear perspective of all on-site developments.

Developing Project Schedules

Conforming to strict schedules for projects prone to delays and errors has been a constant challenge for contractors. Project managers often use labor hours and productivity rates to forecast the deadlines and budget expenses.

If estimates do not stick up to the expectations, management often turns to UAVs and drones to track site issues and bottlenecks. While it helps ensure accountability, you can direct manual labor to tasks that are best suited to their skill set.

Safety Inspections

Drones can access hard-to-reach areas on construction sites offering detailed views for inspectors without putting any human lives at risk. Live imagery helps managers analyze structural integrity, locate potential safety hazards, and ensure everything is in compliance with building safety codes.

In 2021, around 20% of all fatal work injuries in the US occurred in construction, second only to transportation and materials handling.[?]

Choose the right technology for your construction business

Request a demo

3D Printing and Advanced Building Materials

The construction industry is a major contributor to climate change accounting for 39% of global carbon dioxide emissions. [?]But as the world drifts towards sustainable living, the sector has begun adopting modular and green approaches to minimize emissions during construction.

As new trends in construction technology take shape, we witness a growing inclination towards 3D printing, self-healing concrete, bioplastics, and graphene-based materials. 3D-printed homes have gained massive traction from the media as an eco-friendly construction practice that reduces labor costs and eliminates architectural errors.

Today, 3D printing is being explored for infrastructure projects like bridges and viaducts. But there are other innovative materials equally promising for building a sustainable future. To name a few:

-

Graphene. Made from carbon, graphene has exceptional tensile strength and durability, making it a potential reinforcement material for concrete structures. Being lightweight and electrical conductivity makes graphene-based materials viable for energy-efficient systems.

-

Calcium silicate boards. A reliable alternative to traditional gypsum and plywood boards, calcium silicate boards are built from reinforced fibers, which make them fire and moisture-resistant. Their popularity hints at a widespread use in future constructions.

-

Flexible concrete. The toughness of concrete used to be its biggest flaw but not anymore. Bendable concrete, made from fibers and polymers, can withstand high pressures without cracking or losing its structural integrity.

Future Outlook

The concept of a circular economy, which focuses on resource reuse and recycling, is gaining global traction. More and more construction firms are embracing eco-friendly practices with a focus on carbon-free green building and renewable materials. But the latest technologies in construction aren’t limited to that.

Digital twins, 5D BIM modeling, and IoT sensor technologies are used in the construction ecosystem. They foster real-time collaboration between stakeholders to boost efficiency, address worker safety reservations, and facilitate predictive decision-making to prevent losses.

As the world shifts towards smart, sustainable cities, it’s high time for construction firms to join the trend. Embrace these groundbreaking technologies and secure a fair share of the growing economic opportunities.

ERP that saves your money

Adopt FirstBit ERP to cut costs, boost ROI, and effectively plan future cash flows

Request a demo

Final Thoughts

For as long as it counts, humans have been building comfortable and safe dwellings. But as we enter 2026, the focus on eco-friendliness and smart infrastructure has intensified. People are keen to adopt practices that will ensure a safer world for future generations.

Whether you are an individual architect or manage a construction agency, staying informed about the upcoming trends and innovations in the construction sector is crucial.

From building information modeling and IoT analytics to drone-assisted site supervision and construction robotics, the building industry is going through a seismic shift. Ensure you’re at the forefront of this change. Book a demo with us and learn more about FirstBit ERP, the most robust business management software that can take your construction business to the next level.

Abdul Wahab

Content Writer

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.