In construction, efficient procurement is key to staying on schedule and maximizing profits. Yet, many businesses still rely on outdated, slow, and confusing systems that cause delays, drive up costs, and hurt profitability. To stay competitive, it's essential to streamline buying and ordering processes by eliminating unnecessary delays and improving operations.

This article offers practical advice for improving your procurement process. You’ll learn to reduce wasteful spending, automate tasks, and optimize supplier relationships. Plus, we’ll explore common challenges and provide a step-by-step guide to implementing more efficient procurement strategies in your construction projects.

What is the Procurement Process?

Procurement is a systematic approach to optimizing an organization's purchasing process in a way that enables cost savings, time efficiency, and the establishment of mutually beneficial relationships with suppliers.

Steps of Procurement Process

These are the steps involved in the procurement process:

Step 1: Analyze the current state

Evaluate your current vendor relationships, purchasing process, and costs to uncover potential cost savings and create a baseline for measuring progress.

For this, you can review vendor performance reports, track procurement cycle times, and compare historical spending data to industry benchmarks for better insights.

Step 2: Identify the needs

Determine what goods or services you require and in what quantity and quality to clarify your vision for the construction project.

You can consult with project stakeholders, review project plans and past usage data, or conduct market research to ensure accuracy in your estimates.

Step 3: Analyze the supply market

Evaluate potential suppliers by analyzing the market, focusing on evaluation metrics like pricing, service quality, reputation, warranty provisions, and customer service.

To do this effectively:

-

Research supplier reviews on online forums or their website

-

Request quotes and client testimonials

-

Compare service levels

-

Gather feedback from current clients

To evaluate the long-term reliability and scalability of each supplier, also review their financial stability through credit reports, assess their past performance on large projects, and check their capacity to handle increased order volumes.

Step 4: Define your strategy

Set measurable goals, outline a tailored strategy, and use the right tools to streamline procurement, cut costs, and improve supplier relationships.

For this purpose, you can use an ERP system to help you set milestones for a clear view of strategy, reduce losses from any manual costs counts, and maintain an accurate vendor payment calendar to improve relationships.

Step 5: Implement the procurement strategy

Implement your procurement strategy by assigning roles, creating standardized processes like RFP and contract templates, building supplier relationships, and improving supplier performance.

For example, set up regular requisitions in your procurement management software and assign an employee responsible for this process. This will increase the assurance that goods will arrive on time and in the right quantities.

Step 6: Analyze, sum up, and improve

Conduct regular analysis to identify improvement areas and guide long-term planning while reviewing supplier performance to address issues promptly.

For example, in an ERP system, you can use the spend analysis feature to find ways to save money, and also there are tools for trend analysis to predict future needs and guide long-term planning.

Reduce costs and avoid shortages

Optimize procurement with FirstBit

Request a demo

Challenges in the Procurement Process

Procurement faces numerous obstacles that, if not addressed, can severely impact an organization’s bottom line and operations.

1. Unreliable Data

Reliable data is crucial for successful procurement, but many organizations struggle with inaccurate or outdated information. Poor data can lead to bad forecasting, incorrect stock levels, and costly decisions that hurt both financial performance and operations. To succeed, you must prioritize data integrity to support effective procurement strategies.

2. Maverick Spending

Maverick spending happens when purchases are made outside pre-approved contracts or procurement procedures.

This means they buy goods or services from unapproved suppliers or without following the standard process. The problem with this is that it can lead to higher costs because the company might miss out on bulk discounts or better deals from preferred suppliers.

It also introduces compliance risks and weakens relationships with trusted suppliers who expect to handle your business. Controlling this spending is important to save money and streamline the procurement process.

3. Fragmented Supplier Base

Most businesses have a broad and fragmented supplier base to cut down costs. The idea behind this is that with more suppliers, you can create competition among them, which can drive prices down as they compete to win your business.

However, when you have too many suppliers, it often leads to problems. For example, you may have to deal with inconsistent product quality because each supplier might deliver slightly different results. Managing multiple vendors becomes more time-consuming and complicated, and you might miss out on volume discounts since your orders are split across many suppliers. Building strategic partnerships with key suppliers can improve procurement efficiency and long-term value.

4. Poor Negotiation Skills

Inadequate negotiation skills can leave an organization at a strategic disadvantage. This can potentially result in unfavorable terms, lesser value, and strained supplier relationships.

For example, imagine a construction company needs to buy steel for a project. If the procurement manager doesn’t negotiate well, they might accept a price that’s too high or agree to a delivery schedule that doesn’t fit the project timeline.

As a result, the company ends up paying more for the steel than it should and faces delays because the materials arrive late. This increases the project’s overall cost and causes frustration on the construction site, all because the deal wasn’t negotiated properly.

5. Non-Compliance

Compliance with industry regulations and standards is a must for any procurement strategy. Non-compliance can result in legal penalties, financial loss, and damage to an organization's reputation.

Keep the following compliance standards in mind:

-

UAE Building Code. You must ensure that materials and services comply with safety and quality standards outlined in the code.[?]

-

Code of Construction Safety Practice. Procurement decisions must prioritize sourcing from suppliers that adhere to these standards to protect workers (e.g., this applies to equipment such as helmets, safety goggles, and high-visibility clothing.[?]

-

Emirates Green Building Council (EGBC) guidelines. Suppliers and materials chosen should align with sustainability and green building standards supported by EGBC.[?]

-

UAE Labor Law. Suppliers and contractors must undergo vetting to ensure compliance with UAE labor laws and avoid legal and reputational risks.[?]

6. Manual Processes

Paper-based procurement processes can be prone to human errors, such as incorrect order quantities or missing information. These errors lead to delays and inaccurate cost calculations.

Tracking orders manually can make it hard to stay organized. You can face slower approvals and missed deadlines. If you rely on paper-based processes, you can face a significant slowdown in decision-making processes, as documents can get lost or delayed in transit. Additionally, tracking costs become more challenging due to the manual nature of paper record-keeping.

Furthermore, the inability to access and share information quickly prevents you from responding promptly to project needs. This potentially impacts construction project timelines and overall efficiency.

7. Limited Strategic Focus

Limited strategic focus in procurement occurs when businesses concentrate on short-term, day-to-day purchases (tactical procurement) rather than long-term planning (strategic procurement).

While tactical procurement is essential for keeping projects on track, focusing solely on immediate needs can limit your ability to plan bulk purchases or negotiate long-term contracts and hinder your ability to take advantage of cost-saving opportunities.

Strategic procurement involves taking a broader view of purchasing decisions and aligning them with the company's long-term goals and objectives. You can analyze market trends, plan future needs, secure reliable supply chains, and support your construction business's growth over the long term.

Tips for Streamlining Procurement Process

Regularly applying these tips can accelerate your procurement process improvement.

1. Use Data Analytics

Use data analytics in procurement to make smarter buying decisions. Analyzing past purchases can help you identify ways to save money and improve efficiency.

You can also track supplier performance to see if they deliver on time and maintain quality. If you analyze this data, you can avoid potential risks, like delays or poor supplier performance. In this case, you can improve the supply schedule or find new suppliers.

2. Foster Stakeholder Collaboration

To foster stakeholder collaboration in construction, start by understanding the needs of everyone involved — contractors, project owners, engineers, and architects. Clear communication is key to ensuring all parties are on the same page. Keep information flowing to prevent misunderstandings and improve project outcomes.

3. Centralize Procurement Management

Centralizing procurement management is a key strategy that brings together all purchasing activities under one roof. By setting up a dedicated procurement department or team, you can have better control and oversight of your procurement process.

4. Implement Vendor Performance Evaluation

Evaluate vendor performance regularly to strengthen supplier relationships and prevent supply chain disruptions. Strong supplier partnerships reduce bottlenecks and ensure timely deliveries. With a solid relationship, suppliers can offer insights, alert you to issues early, and help your business stay on track.

5. Implement Strategic Sourcing

Use strategic sourcing to optimize procurement by focusing on long-term value, not just cost. Evaluate suppliers based on reliability, product quality, and delivery speed to build stronger relationships, negotiate better deals, and reduce supply chain risks. An ERP system can help analyze supplier data and track performance to ensure you make the best project choices.

6. Monitor Inventory Levels

Monitor inventory levels closely throughout the procurement process to avoid shortages and keep construction projects on track. By tracking stock in real-time, you can prevent overstocking, reduce waste, and ensure materials are available when needed.

7. Establish Secure Supplier Relationships

Build secure supplier relationships as part of your procurement process to ensure reliable material deliveries on time. Strong partnerships allow you to negotiate better terms, e.g., special discounts or convenient delivery times for supplies.

8. Manage Regulatory Compliances

Stay on top of regulatory compliance to avoid legal penalties, project delays, and costly rework. Compliance with safety standards, labor laws, and building codes is key to reducing risks and maintaining smooth project flow.

9. Automate the Procurement Process

Automate your procurement process to boost efficiency, cut manual errors, and save time in your construction business. Use software to streamline tasks like purchase orders, vendor selection, and invoice management, leading to faster approvals and better cost control.

As software for better procurement process management, you can use ERP systems. For example, FirstBit ERP meets all requirements and can help you:

-

Provide tools to analyze data, such as supplier tables detailing product information, price, delivery time, etc.

-

Help improve communication between parties through dialog sections and comments that parties can leave to enhance workflow.

-

Centralize procurement management because, in the system, you can make a requisition for goods and observe their movements in real time. In parallel, you can monitor the allocation of the procurement budget.

-

Monitor the level of goods in the warehouses thanks to the FirstBit ERP inventory module, which allows you to view the available stock in time and make a request in a timely manner.

-

Maintain good relations with suppliers by paying accounts payable on schedule.

Build reliable partnerships with suppliers

Request a demo

How to Choose the Best Procurement Software?

Choosing the right procurement software is essential for improving your construction business because the right system can cut costs and streamline your procurement process.

When exploring options, it’s worth considering ERP systems, as they offer comprehensive tools to manage crucial aspects like inventory and supplier relationships. This helps you stay organized and efficient across all projects.

Let's take a look at the important criteria when choosing a system:

- Real-time tracking. The software should provide real-time updates on inventory levels, order statuses, and supplier performance.

- Ease of integration. Ensure the software integrates smoothly with your existing systems (like accounting, inventory, and project management tools).

- User-friendly interface. Choose software that's easy for your team to learn and use, with a clean interface and intuitive navigation.

- Customizable features. Make sure it allows you to customize workflows, reporting, and templates to fit your specific needs.

- Supplier management tools. Look for tools to track supplier performance, manage contracts, and handle multiple vendors efficiently.

- Budget and cost control. Ensure the system offers clear visibility of procurement costs and budget tracking to help manage expenses.

- Scalability. Choose software that can grow with your business, supporting larger projects and increased procurement needs as you expand.

- Compliance tracking. The system should help you stay compliant with industry regulations, safety standards, and legal requirements.

- Customer support. Make sure the vendor offers reliable customer service and ongoing support to resolve any issues quickly.

Choosing the wrong procurement system can cause inefficiencies, raise costs, and lead to missed deadlines. When selecting software, it's crucial to thoroughly evaluate the key factors we pointed out above to ensure they align with your construction business-specific requirements. Overlooking these aspects could lead to software not being tailored to your needs, resulting in workflow insufficiencies.

How Can First Bit Help in Streamlining the Procurement Process?

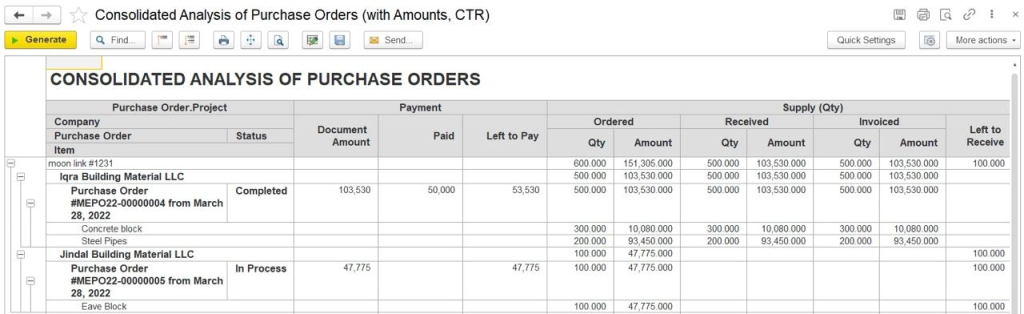

Automated Purchase Orders

Procurement module of First Bit ERP system helps you automate the purchase orders generation when inventory levels drop below a certain threshold. This ensures materials are ordered at the right time, reducing manual work and preventing delays in the procurement process.

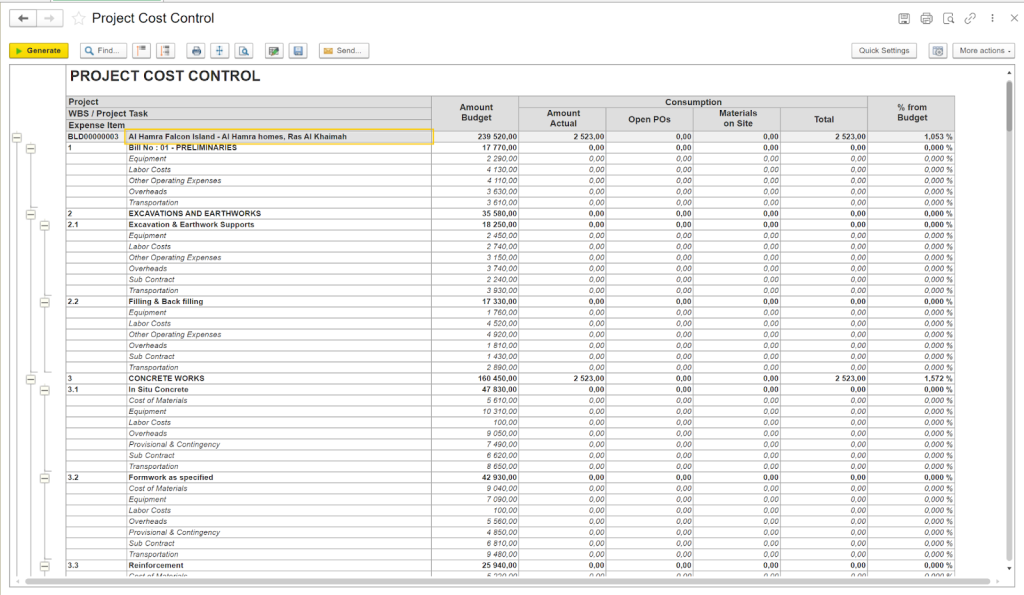

Project Cost Control

FirstBit ERP will help you empower proactive cost control. With its features, you can set up real-time alerts for any budget deviations, ensuring you’re immediately notified if spending exceeds limits. The system enforces strict spending controls by allowing you to set predefined limits, preventing overspending before it happens.

Additionally, FirstBit ERP streamlines budget management by facilitating approval workflows for budget adjustments, ensuring that any changes are properly reviewed and authorized. This level of control helps keep your projects on budget while promoting financial accountability throughout the entire procurement cycle.

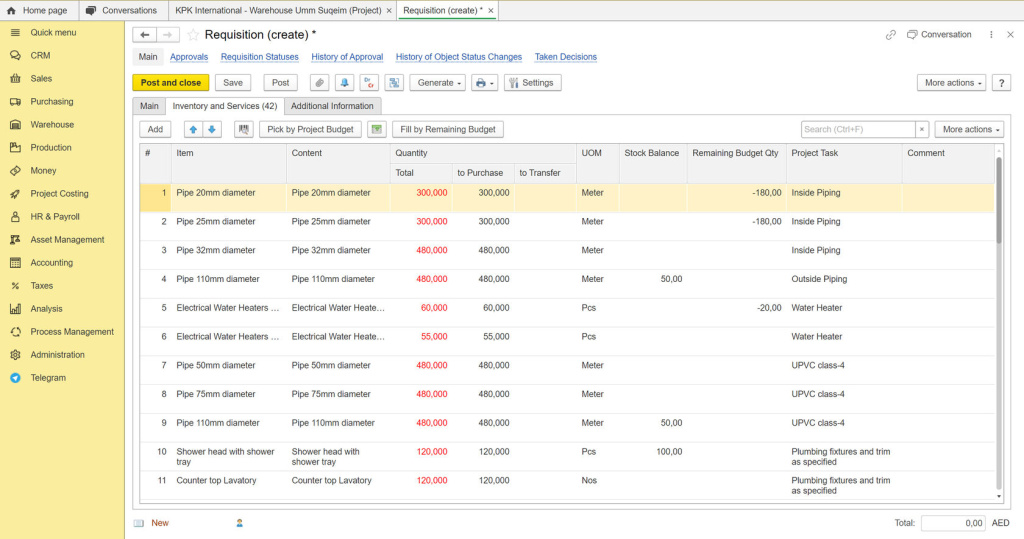

Requisition Control

Centralize all your requisitions for easy access with FirstBit ERP. All your applications, along with detailed information, are organized in a single tab. You can track their status and required dates in real time, helping you manage your time more efficiently and further streamline your procurement process.

Get top-quality materials

Streamline procurement with FirstBit

Request a demo

Anna Fischer

Construction Content Writer

Related terms

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.