Enterprise Resource Planning (ERP) systems are at the heart of digital transformation. They connect finance, operations, HR, and project management into a single platform, giving leaders real-time visibility and control. But while the benefits are undeniable, ERP failures are far more common than many executives expect.

One of the clearest warning signs is how frequently projects run over budget. When companies underestimate staffing needs, data migration complexity, or training requirements, the financial impact quickly escalates.

Less than half of ERP projects are delivered within their original budget[?].

This statistic highlights the significant cost of ERP mistakes. The overruns aren’t limited to the budget; they usually coincide with delays, frustrated users, and systems that never achieve full adoption. The truth is, ERP mistakes often stem from poor decisions made during software selection or from weak execution during rollout. Avoiding them requires a clear strategy, realistic planning, and strong business-led leadership.

Why ERP Mistakes Are So Costly

Main reasons why ERP mistakes are so costly

ERP is not just another piece of software. It’s the backbone of modern organizations, integrating finance, supply chain, HR, projects, and customer management into a single system. Because it touches every process, even small ERP mistakes can snowball into company-wide problems.

There are three main reasons why these mistakes become so expensive:

- ERP impacts every department. Unlike a standalone tool, an ERP system connects accounting, procurement, payroll, operations, and reporting. An ERP error in setup or configuration doesn’t stay contained; it disrupts workflows across the entire organization. For example, a mistake in the chart of accounts setup may cause reconciliation issues in finance, delayed purchasing approvals, and inaccurate project cost tracking, all from a single error.

- The scale of investment is huge. ERP projects demand significant budgets, manpower, and executive attention. When they go wrong, the financial impact isn’t just the overspend; it’s the lost opportunity cost. Delays in implementation stall efficiency gains, while hidden costs like data cleanup, integrations, and user support drain resources. Companies often underestimate this, which is why budget overruns and timeline slippages are so common.

- ERP failures damage adoption and trust. When employees experience broken workflows or aren’t trained properly, they lose confidence in the system. Instead of improving productivity, the ERP becomes something workers avoid, relying on manual spreadsheets or workarounds. This leads to data fragmentation, reporting errors, and wasted investment.

In short, ERP mistakes are costly because they hit finances, operations, and people at the same time. They delay digital transformation, erode employee trust, and turn what should have been a growth enabler into a costly liability. Avoiding these pitfalls requires treating ERP as a business transformation initiative with clear goals, realistic budgets, and full stakeholder involvement.

Common ERP Software Selection Mistakes

ERP success doesn’t begin with go-live; it begins with choosing the right system. Many companies underestimate how critical the software selection phase is, rushing through requirements or relying too heavily on vendor promises. The reality is that most ERP implementation mistakes originate here. Once the wrong system is chosen, no amount of project management or training can fully compensate.

Selection mistakes don’t just cause ERP errors during rollout; they define the long-term usability and cost of the system. A mismatch between the ERP and your industry, a lack of focus on business priorities, or skipping a cloud strategy often results in customizations, higher costs, poor adoption, and eventually ERP failures. In fact, by the time problems show up during implementation, they usually trace back to decisions made at the selection stage.

This makes ERP selection one of the most consequential phases in the entire project lifecycle. Getting it wrong sets the stage for years of inefficiency; getting it right gives you a system that scales with your business and delivers sustainable value.

Assuming One ERP Fits Every Industry

No two industries are alike. Yet one of the biggest ERP software selection mistakes is assuming a generic ERP can cover all business needs. While many systems handle core accounting or HR, they often fail when it comes to sector-specific requirements.

Take construction as an example: companies need project-based accounting, subcontractor control, retention payments, and cost tracking by work breakdown structures (WBS). A generic ERP built for retail or distribution won’t have these out of the box. The result? Costly customizations, frustrated end-users, and processes that still fall back to Excel.

Tip: Always demand industry-specific demonstrations. If the vendor can’t show your exact workflows, like progress billing or site payroll, without heavy customization, that’s a red flag.

Focusing on IT Instead of Business

Another trap is letting the IT team dominate ERP selection. While technical considerations (security, infrastructure, integration) matter, ERP is first and foremost a business system. If business leaders and frontline users aren’t central to the decision, the result is often a technically sound system that no one actually wants to use.

This misalignment shows up in poor adoption, “shadow systems” like spreadsheets, and leaders not trusting the reports. In short, you get ERP errors not because the software is broken, but because it doesn’t fit real processes.

Tip: Build a cross-functional selection team. Finance, HR, operations, and project managers should be at the table alongside IT because they’re the ones who will use it daily.

Not Choosing Cloud ERP

ERP is moving to the cloud, yet many businesses still evaluate solutions as if on-premises were the default. This is a critical misstep:

cloud ERP now dominates new deployments, and failing to account for it often means higher capital expenditure, slower upgrades, and weaker resilience.

By 2025, 85% of organizations will embrace a cloud-first principle for ERP and other digital platforms[?].

This trend highlights that choosing an on-premise-only ERP isn’t just old-fashioned. It risks putting your business at odds with where the industry is heading.

Cloud ERP allows distributed teams to access data securely, improves disaster recovery with automated backups, and enables scalability without the heavy upfront investment of hardware.

Tip: Unless regulation requires otherwise, the cloud should be your baseline. Confirm that the vendor offers encrypted backups, data redundancy, and service-level agreements (SLAs) that guarantee uptime and recovery.

Overlooking Standardization Limits

Every ERP promises standardization, but none can cover every internal process exactly as-is. Companies that assume “the system will do everything” usually end up in one of two traps: either over-customizing (making upgrades painful) or forcing users into workflows that don’t make sense.

The smartest approach is to strike a balance: adapt some processes to fit the ERP, and only customize where differentiation truly adds value. Failing to maintain this balance creates long-term maintenance burdens and higher costs.

Tip: Before selection, map your processes into three buckets: (1) must be standardized, (2) must be customized, (3) flexible. This avoids unrealistic expectations and prevents you from bending the ERP in ways it was never designed for.

Gain full control of your business

Get a 360° project view with FirstBit ERP

Request a demo

Common ERP Implementation Mistakes

Even with the right ERP system selected, the implementation stage is where most failures occur. Rollouts are complex, touching every department, process, and employee. When mistakes happen here, they aren’t small—they derail entire projects, create frustration, and waste significant investment. Below are the most common errors that lead to ERP failures, along with strategies to avoid them.

Skipping Strategic Planning Before ERP Implementation

ERP implementations often stumble because companies rush into configuration without a clear vision. Without defined objectives, KPIs, or success measures, projects quickly lose direction. Teams may spend months setting up modules, only to realize the system doesn’t align with the company’s real priorities.

This lack of clarity also breeds miscommunication. Finance expects faster reporting, operations want smoother procurement, but IT focuses on infrastructure stability. Without alignment, each department pushes in a different direction, resulting in scope creep and rising costs.

Tip: Define measurable goals at the start, like “reduce invoice processing time from 10 days to 3” or “consolidate financial reporting across all projects.” Clear outcomes guide design decisions and create a benchmark to measure success.

Overextending the Planning Phase

On the flip side, some companies spend so much time in the planning stage that implementation momentum dies. Endless workshops, revisions, and documentation stall progress while employees grow frustrated with the lack of visible results.

ERP isn’t meant to be perfect on day one; it should evolve. Companies that overplan often end up with outdated assumptions by the time the system actually launches.

Tip: Strike a balance. Prioritize critical scope items for go-live and handle secondary needs in later phases. Use agile methods or phased rollouts to deliver early wins while refining over time.

Underestimating the Role of Stakeholders

ERP projects fail when they are treated as “IT-only.” Excluding finance managers, HR leads, or frontline employees creates a system that looks good technically but doesn’t reflect real business workflows. Users then resist the system, adoption lags, and productivity drops.

Stakeholder neglect also increases change resistance when people feel decisions are imposed rather than co-created; they push back harder.

Tip: Involve stakeholders early and often. Engage them in requirements gathering, design workshops, and testing. This builds ownership and ensures the system reflects how people actually work.

Failing to Plan for Budget Overruns and Hidden Costs

ERP projects are notorious for budget blowouts. The initial quote rarely includes data cleanup, integration with legacy systems, additional licensing, or ongoing support. Companies that don’t plan for these extras often face mid-project funding battles or scope cuts that weaken the system.

Tip: Budget beyond software and consulting fees. Include training, change management, data migration, and post-go-live support. Build a 15–20% contingency buffer to absorb surprises without jeopardizing the project.

Cutting Corners on Training and Expecting Users to “Figure It Out”

An ERP system is only as good as the people using it. Too many companies assume employees will “learn on the job,” which leads to mistakes, reliance on spreadsheets, and resistance to change. Without training, adoption plummets, and the ERP never delivers its intended ROI.

Poorly trained employees also flood IT and support teams with tickets, creating avoidable costs and frustration.

Tip: Deliver role-based training tailored to how employees use the system daily. Reinforce with workshops, e-learning modules, and refresher sessions. Training should be ongoing, not a one-time event.

Rushing or Mishandling Data Migration

Data is the lifeblood of an ERP system. If bad data is imported, duplicate vendors, inconsistent product codes, and outdated employee records, the system produces unreliable reports from day one. Poor mapping or incomplete migration also breaks integrations, causing operational chaos.

Fixing these problems post go-live is far more expensive than cleaning data upfront.

Tip: Audit and cleanse legacy data before migration. Run multiple test migrations and validate results with business users. Ensure integration with payroll, CRM, or project systems is tested thoroughly before launch.

Over-Customizing the System Instead of Streamlining Processes

ERP customization is a double-edged sword. While some tailoring is necessary, excessive modifications create fragile systems that are hard to upgrade and expensive to maintain. Companies often try to replicate every old process, even inefficient ones, instead of using ERP to drive process improvement.

Over-customization also ties you too closely to specific consultants or developers, creating long-term dependency risks.

Tip: Follow the principle: configure first, customize last. Use standard ERP functionality wherever possible, and only customize if it creates a clear competitive advantage or regulatory compliance.

Setting Unrealistic Timelines Without Accounting for Business Cycles

Pushing for an aggressive go-live without considering the company’s business cycle is another critical error. For example, rolling out ERP during financial year-end, peak sales season, or major project deadlines creates stress and errors. Teams already overloaded with business-critical tasks can’t give ERP rollout the focus it requires.

The result? Missed deadlines, skipped testing, and half-prepared users all of which compromise ERP success.

Tip: Plan go-live dates around low-activity periods. Avoid critical windows like fiscal close or peak project phases. Build in buffer time for testing, training, and phased adoption.

Choosing the Right Partner — Why FirstBit ERP Stands Out

Selecting an ERP vendor is as critical as choosing the software itself. A strong system can still fail if the implementation partner lacks domain experience, local compliance knowledge, or reliable support.

FirstBit ERP distinguishes itself in the construction and contracting space through industry focus, regulatory expertise, and strong customer support.

Industry-Specific Capabilities

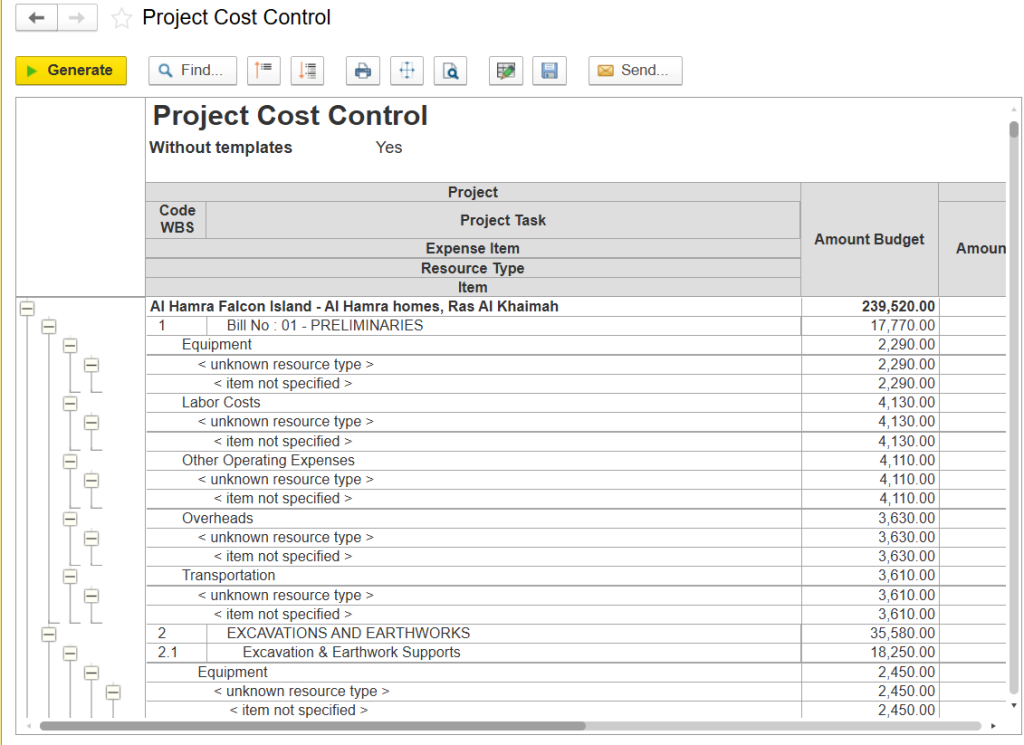

FirstBit ERP is built specifically for construction and contracting businesses, rather than being a generic ERP with add-ons. Its modules include BOQ-based estimating, project cost control, progress billing, and project-specific cost allocations. Because these capabilities are native, they reduce the need for heavy customization, lowering the risk of ERP mistakes from misfit workflows or complex overrides. An ERP system reduces errors when it matches industry-specific processes out of the box, rather than relying on workarounds.

Project cost control report in FirstBit ERP

Local Compliance Expertise

In the UAE, compliance with VAT, labor law, and corporate tax is non-negotiable. FirstBit provides automated VAT modules and tracks labor compliance (e.g., payroll, leave, end-of-service provisions) within the system. As a UAE-based company with over a decade of presence in the region, FirstBit also has insight into local regulatory changes and market nuances.

Integrated Business Functions

FirstBit ERP integrates finance, procurement, HR, project operations, and reporting into a unified platform. This removes data silos and ensures consistency across departments. By consolidating processes into one platform, an ERP system reduces errors that usually occur when teams work across disconnected tools.

Training and Support

Choosing the right partner also means access to support, implementation guidance, and flexibility. FirstBit offers in-depth user training to help teams adopt the system smoothly, hotline support and dedicated account management to handle issues quickly, and customization options when needed, balanced with recommendations to preserve upgradeability. These elements ensure that FirstBit is not just a SaaS provider, but a partner through the ERP lifecycle.

Proven Regional Presence

With more than 2,000 companies in the UAE using its digital solutions, FirstBit has a strong footprint in the region. The ability to scale across multiple projects, companies, and regions while maintaining compliance and support is a major advantage, especially in the dynamic construction environment.

Explore efficient ERP solutions for your construction business

Request a demo

Conclusion

ERP projects are among the most complex initiatives a business can undertake. When handled correctly, they become powerful enablers of efficiency, accuracy, and growth. But as this article has shown, ERP implementation mistakes and ERP software selection mistakes are common and costly, often stemming from weak planning, misaligned priorities, or the wrong partner.

The good news is that these pitfalls are avoidable. Companies that approach ERP as a business-led transformation, involve stakeholders early, and plan realistically are far more likely to succeed. Equally important is choosing a partner with proven expertise, local compliance knowledge, and industry-specific solutions qualities that help reduce ERP errors and ensure long-term scalability.

For organizations in construction and contracting, especially, the difference between an ERP that adds complexity and one that drives transformation lies in the details: understanding unique workflows, staying compliant with local regulations, and having access to continuous support. With the right approach and the right partner, ERP doesn’t just replace old systems; it lays the foundation for sustainable digital growth.

FAQ

What should I ask during an ERP product demo to avoid future regrets?

Don’t just rely on the vendor’s scripted walkthrough during an ERP demo. Ask targeted questions that reveal gaps and how the system performs in real-world use. For instance, request a demonstration of one of your actual workflows, such as subcontractor billing or multi-project reporting.

Clarify which features work out of the box and which require customization, and be specific about licensing terms, including potential user caps, hidden module fees, or integration costs. Finally, assess how reporting works in practice, ensuring that non-technical users can generate reports without depending on IT. The goal is to look beyond polished screens and evaluate how well the ERP fits your business day-to-day.

Can I switch ERP systems mid-implementation if it’s not working out?

It’s possible, but it comes with significant risks and costs. By the time problems become obvious, contracts are usually signed, data migration is underway, and staff are already trained on the chosen platform. Switching vendors midstream often means writing off sunk costs and restarting project phases from scratch.

If early warning signs emerge like misalignment with workflows, lack of vendor responsiveness, or repeated scope changes, they should be escalated quickly. In some cases, it’s better to pause and renegotiate with the existing vendor than attempt a complete switch.

How do I validate that an ERP vendor’s references are actually reliable?

Vendor references are often cherry-picked. Go beyond the polished success stories. Ask for references in your specific industry and of similar size/complexity. Request direct contact details and have candid conversations with actual users. Search for independent customer feedback on professional forums or LinkedIn groups. Ask references about the challenges they faced, not just the benefits. A reliable vendor won’t hesitate to share lessons learned.

What red flags should I watch out for in ERP contracts?

Be alert to vague or one-sided clauses when reviewing ERP contracts, as they often hide long-term risks. An undefined scope of work can leave room for costly “change requests,” while the absence of fixed timelines or milestones may allow implementations to drag on indefinitely.

Expensive exit or termination clauses can trap you with the vendor, and overly broad customization terms may force you to rely on them for every change, driving up costs over time. To avoid these pitfalls, have contracts reviewed not only by legal experts but also by functional stakeholders who understand how the ERP will be used day-to-day.

Should I prioritize ERP vendors who specialize in my country or region?

Yes. Local expertise often makes a significant difference, especially for compliance-heavy industries. Vendors with a regional presence understand local tax rules, labor regulations, reporting standards, and even language nuances. They also offer faster support due to proximity and often have relationships with regional regulators and auditors.

For businesses in markets like the UAE, choosing a vendor with proven local experience reduces risks and ensures smoother adoption.

Stay on track with your goals

Monitor KPIs with FirstBit ERP

Request a demo

Umme Aimon Shabbir

Editor at First Bit

Aimon brings a deep understanding of the modern construction business to her articles by providing practical content.