A successful construction project doesn’t begin on site; it starts on paper, with precise planning. Before budgets are finalized, materials are ordered, or timelines are committed, there's one foundational task that determines the accuracy of everything that follows: the construction takeoff.

Done correctly, it becomes the basis for cost estimation, procurement, and bid preparation. Done poorly, it leads to costly overruns, procurement delays, and missed opportunities. In this article, we’ll break down what construction takeoff actually is, its role in a project’s lifecycle, and why it’s essential for contractors who want to stay competitive without compromising on profit or execution.

What is Construction Takeoff?

Construction takeoff refers to the process of identifying and quantifying all materials required to complete a construction project. It is the first step in the estimating process, not to be confused with cost estimation, and focuses purely on material scope and measurements.

Estimators and project managers typically extract these quantities directly from project drawings, blueprints, or 3D models. Every component, whether it’s cubic meters of concrete, square meters of flooring, or the number of windows and doors, is counted and calculated using standardized units.

The goal is to produce a detailed list of what’s needed and how much, so that cost estimations, procurement schedules, and labor allocations can be based on hard data instead of guesswork.

Objectives of Construction Takeoff

A construction takeoff isn’t just a checklist of materials — it’s a strategic document that influences multiple phases of a project. From

cost estimation and bidding to procurement and sustainability, its impact goes beyond quantity tracking. Below are the key objectives that make takeoff a critical part of any construction workflow.

Accurate Project Cost Estimation

Takeoff serves as the foundation for all financial planning in a construction project. Without a clear understanding of material quantities, cost estimators have no reliable input for pricing. This often leads to budget overruns, especially in complex projects.

According to a 2022 study by McKinsey, large construction projects typically take 20% longer to finish than scheduled and run up to 80% over budget, largely due to inaccurate forecasting and miscalculations in the early planning phases[?].

By identifying exact quantities early on, takeoff enables the cost estimator to assign realistic pricing for each material, which supports better planning and financial control across the project lifecycle.

Competitive Bidding

In a market where margins are tight and clients demand transparency, accurate takeoffs play a central role in producing competitive bids. Contractors use takeoffs to determine their direct costs, the foundation upon which profit margins and markup are calculated.

Underestimating materials can lead to underbidding, which puts the contractor at risk of losses during execution. Overestimating, on the other hand, inflates the bid and can cost them the contract. A well-prepared takeoff allows contractors to bid confidently, knowing their pricing is neither aggressive nor padded with risk buffers.

This level of precision is particularly crucial in public sector or high-value private projects, where small deviations in pricing can shift bid rankings.

Efficient Procurement Planning

Procurement teams rely on construction takeoffs to order materials in the correct quantities and within the required timeframes. When takeoffs are inaccurate, it can disrupt the entire construction sequence, either by delaying activities due to material shortages or by overstocking, which unnecessarily ties up capital and storage space.

By providing a detailed breakdown of material needs upfront, takeoffs enable procurement teams to plan purchases with confidence. This not only ensures materials are delivered when needed but also helps maintain the project’s workflow and budget. Effective procurement depends on clear, reliable data, and that starts with a precise takeoff.

Sustainability and Waste Reduction

Construction takeoffs directly contribute to reducing material waste. When estimators know exactly what is required, they avoid over-ordering, which not only saves money but also reduces environmental impact.

The construction industry is responsible for roughly 30% of global waste, according to the World Bank. Much of this stems from unused or excess materials ordered without precise takeoff calculations[?].

By optimizing quantities at the planning stage, takeoff supports sustainable construction practices and helps companies meet green building standards or LEED certification requirements. It also aligns with cost efficiency, as less waste means fewer disposal costs and better margins.

Align every purchase with project goals

Track supplier performance and control costs

Request a demo

Who Performs Construction Takeoff Services

The accuracy of a construction takeoff depends not only on tools and techniques but also on the professionals performing the task. While the level of complexity varies from one project to another, responsibility for takeoff preparation is typically divided based on trade, scope, and project size.

Estimators and Quantity Surveyors

These are the primary professionals tasked with producing detailed takeoffs for medium to large-scale projects. They follow standard measurement methods and often work with digital software to meet the demands of tight deadlines and multiple revisions. Their work forms the basis of technical evaluations during tendering and scope finalization.

Contractors and Subcontractors

In smaller projects or within specific trades, subcontractors often perform takeoffs limited to their scope — for instance, a flooring contractor handling just the tile and underlayment. These are generally simpler, component-specific takeoffs that feed into the overall bid prepared by the general contractor.

Specialized Roles in Large Projects

In complex projects, takeoff responsibilities are distributed further:

-

MEP Estimators quantify HVAC systems, ductwork, plumbing lines, and electrical components.

-

Structural Estimators handle materials like reinforcement bars, concrete volumes, steel connections, and framing.

-

Finishing Estimators cover internal finishes, including partitions, ceiling grids, paint, and tiling.

This level of specialization helps maintain accuracy in multidisciplinary environments and improves coordination between estimation, planning, and execution teams.

Measurement Methods in Construction Takeoffs

Once drawings are received, materials are quantified using predefined measurement methods depending on how they’re installed or applied. These methods are standardized to maintain consistency across estimating teams and procurement schedules.

|

Measurement method

|

What is it’s used for

|

|

Count

|

Discrete items like fixtures, windows, doors, or equipment units

|

|

Area (ft² or m²)

|

Surface-based installations like drywall, tiling, and insulation

|

|

Volume (ft³ or m³)

|

Bulk-fill materials such as concrete, backfill, and grout

|

|

Length (lf or m)

|

Continuous elements such as piping, conduits, cabling, or trims

|

By aligning the unit of measurement with the material type, estimators ensure consistency during both estimation and procurement, minimizing confusion or conversion errors downstream.

Choose the best suppliers

Request a demo

Types of Construction Takeoff

Not all takeoffs follow the same process or format. The method you choose depends on the project’s complexity, the available tools, and the team's experience. Below are the commonly recognized types of construction takeoffs used across the industry:

Material vs. Quantity Takeoff

These two approaches serve different but complementary purposes in the estimation process.

|

Type

|

Focus

|

|

Material takeoff

|

Identifies specific product types and specifications required (e.g., 12mm gypsum board, PPR pipes)

|

|

Quantity takeoff

|

Focuses on numeric calculations (e.g., 800 m² of drywall, 120 m of piping) without specifying brand or spec

|

Material takeoffs are often used later in the tendering or procurement stage, while quantity takeoffs are generated earlier for budgeting and scope definition.

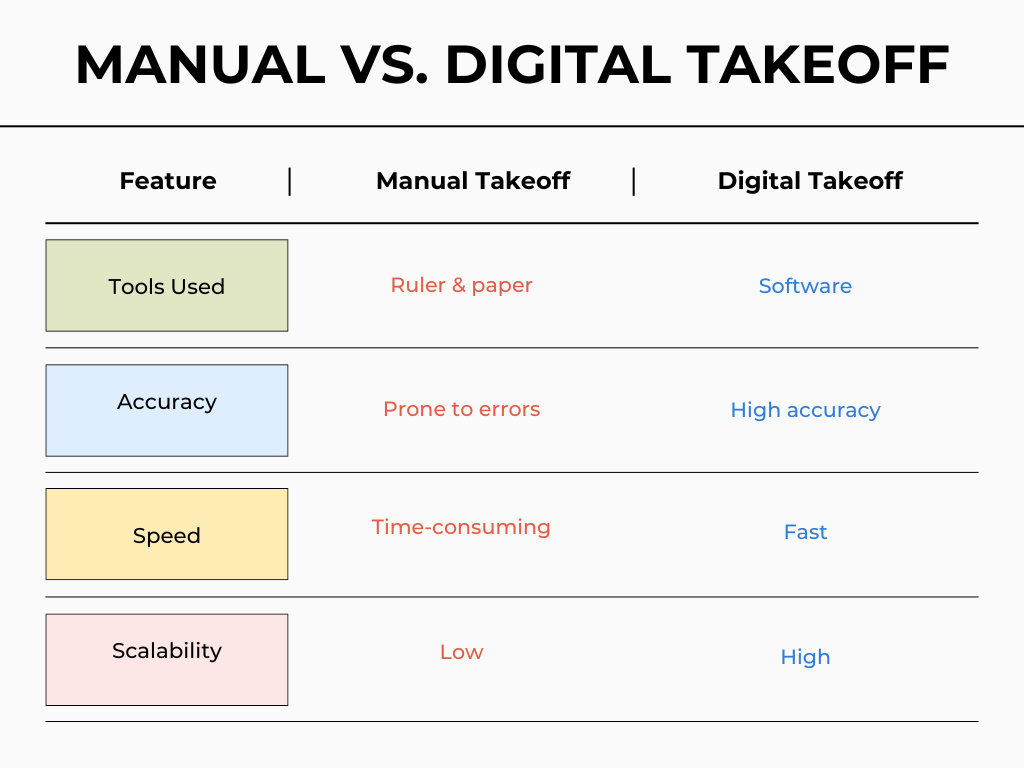

Manual Takeoff

Manual takeoffs involve reading printed blueprints, measuring with a scale, and entering quantities into spreadsheets. This method is labor-intensive and more prone to miscalculations, especially in large or frequently revised projects.

Despite being traditional, manual takeoffs are still used:

-

On small projects with limited scope

-

Where digital access is restricted

-

By trades with routine, standardized installations

However, they offer limited flexibility when handling multiple revisions, collaborative workflows, or large datasets.

Digital Takeoff

Digital takeoffs have become the industry standard for teams managing high-volume or complex projects. By replacing manual measurements with digital workflows, these tools enable faster, more accurate quantity calculations directly from uploaded project drawings.

Estimators can mark measurements, define material categories, and generate quantity summaries without relying on printed plans or scale rulers. Modern digital tools also allow for layered breakdowns by trade, floor level, or system type, which makes organizing takeoff data easier when working across multiple scopes.

Key advantages of digital takeoffs include:

-

Measurement consistency. Built-in scale calibration reduces unit errors and ensures standardization across project files.

-

Auditability. Changes to measurements or quantities can be tracked and reviewed, helping teams manage revisions more effectively.

-

Centralized access. Takeoff files, quantity reports, and markup history are stored digitally, allowing multiple users to access and review data without physical paperwork.

In many cases, teams integrate digital takeoff tools with estimation or

ERP systems to streamline handovers and maintain data continuity. This eliminates redundant data entry and supports clearer coordination across preconstruction and procurement.

Comparison Between Manual Vs Digital takeoff

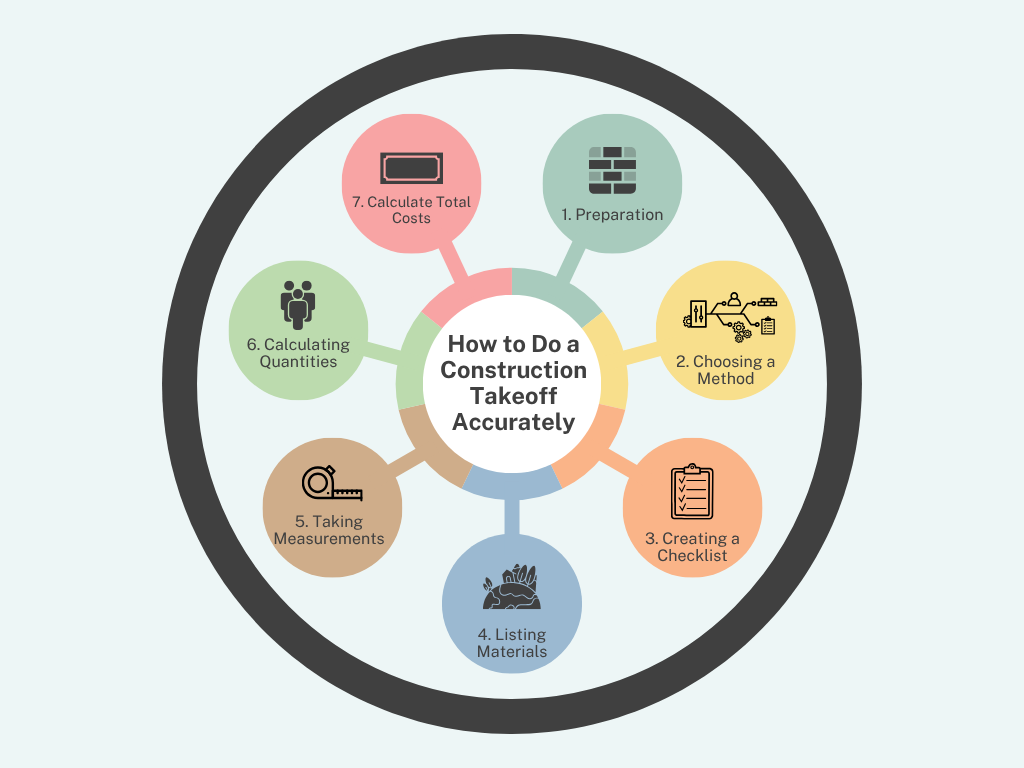

How to Do a Construction Takeoff Accurately

An accurate construction takeoff depends on more than just counting materials. It requires a structured, repeatable process that minimizes oversight and supports traceability. Whether you’re working manually or using digital tools, following these core steps helps ensure every component is captured with precision.

1. Preparation

Before any measurements begin, carefully study the architectural and engineering drawings, along with project specifications. Confirm that you have the most up-to-date versions and review all relevant sheets, including structural, MEP, and finishing plans.

Understand the full scope of work: Are there any design alternates? Will there be prefabricated components? Are special finishes or imported materials involved? Clarifying these early avoids scope creep and ensures nothing is overlooked during quantity extraction.

2. Choosing a Method

The next step is to determine how the takeoff will be performed. Your choice depends on project complexity, timeline, and available tools.

-

Manual method. Traditional approach using printed drawings, a scale ruler, and spreadsheets. Suitable for small or one-trade scopes, but prone to human error and rework during revisions.

-

Digital method. Involves uploading drawings into takeoff software that automates measurement and categorization. Allows for faster calculations, easier revision tracking, and integration with estimating systems. Teams managing multiple concurrent bids or working under tight deadlines typically prefer digital takeoff platforms for their efficiency and auditability.

3. Creating a Checklist

Before listing items, develop a checklist that includes all expected materials and work categories relevant to the project scope. This ensures you don’t miss standard components, such as underlayment in flooring or hangers in ductwork.

Standardized checklists also support internal consistency, especially in teams where multiple estimators are working in parallel, and simplify future takeoffs for similar project types.

4. Listing Materials

List every component required to execute the project, broken down by category and trade. Avoid general terms like “tiles” or “lumber.” Instead, be specific:

-

300x300mm porcelain tile, matte finish

-

12mm gypsum board, fire-rated

-

20mm steel reinforcement bar, B500B

-

25mm PVC electrical conduit

-

6-panel solid core internal door

Using precise descriptions avoids procurement mismatches and ensures alignment between estimation, purchasing, and site execution.

5. Taking Measurements

Using the project’s specified drawing scale (e.g., 1:100, 1:50), begin measuring the required items. Ensure the scale on the document is accurate, particularly if the drawings were printed or plotted, to prevent quantity miscalculations.

For digital methods, verify that the correct scale has been set in the software. Tools like “snap to length” or “polygonal area” help ensure clean inputs even in irregular layouts.

Focus on dimension consistency across materials. For instance, don't mix linear and area measurements for the same scope, as this creates confusion during procurement and cost tracking.

6. Calculating Quantities

After measurements are recorded, calculate quantities based on the corresponding unit of measure for each item:

-

Use linear meters (lm) for piping, conduits, trims

-

Use square meters (m²) for flooring, drywall, or waterproofing.

-

Use cubic meters (m³) for concrete, backfill, and insulation.

-

Use the number of units for fixtures, doors, or equipment

Always apply a waste factor depending on the material and construction method. For example, ceramic tile may require 5–10% overage for cuts and breakage, while steel reinforcement might include a margin for overlaps and bends.

These adjustments should be visible in the final takeoff sheet, not hidden within base quantities, to keep the calculations auditable.

7. Calculate Total Costs

Once your quantities are finalized, assign current unit costs to each line item, sourcing from supplier catalogs or internal pricing databases. Include a clearly labeled buffer for materials with volatile prices.

Multiply quantities by unit costs to create line-item subtotals, then sum those to determine the preliminary material cost, which directly feeds into your project estimate.

Many modern takeoff tools automate this process, pulling live pricing as you work. This eliminates manual errors and ensures consistency across bids and procurements.

A study published in the International Journal of Built Environment and Sustainability found that rework can add up to 12.6% of the total project cost, often due to inaccurate quantity measurements or scope misinterpretation during early stages[?].

This highlights the value of accurate takeoff and cost-planning processes because errors at the takeoff stage can significantly impact overall margins.

By building your cost estimate on precise takeoff data, you reduce the risk of budget overrun due to rework or pricing mistakes and maintain tighter control over project profitability.

Get top-quality materials

Streamline procurement with FirstBit

Request a demo

Why Use a Construction Takeoff Spreadsheet?

While many contractors have adopted digital takeoff tools, spreadsheets remain widely used in the industry, particularly by small to mid-sized firms or teams just beginning to systematize their processes. Below are practical reasons why construction takeoff spreadsheets are still valuable:

-

Accessibility. Takeoff spreadsheets can be created in Microsoft Excel, Google Sheets, or other spreadsheet programs that are already installed in most workplaces. No additional software or licenses are required.

-

Customization. Spreadsheets can be easily tailored to suit the project type, company format, or specific client reporting needs. Whether you're preparing a residential scope or a trade-specific takeoff, you can adjust columns, formulas, or tabs accordingly.

-

Transparency. A structured spreadsheet allows team members and stakeholders to review how quantities were calculated. This improves traceability and helps during scope clarifications or change order negotiations.

-

Affordability. For businesses that haven’t invested in full-scale estimating software, spreadsheets offer a cost-effective way to produce detailed material takeoffs without compromising on structure.

-

Familiarity. Most estimators already use spreadsheets for some part of their workflow. For those not yet working in digital takeoff platforms, spreadsheets provide a familiar interface to organize quantities, costs, and measurement notes.

While spreadsheets have limitations in large or frequently changing projects, they are still a dependable solution when used with clear formatting, version control, and peer reviews.

Material Takeoff Sheets: Step-by-Step Plan

Key Stages in a Construction takeoff

Creating a reliable material takeoff sheet requires more than listing a few materials and prices. To ensure accuracy and consistency across your projects, follow these eight structured steps:

1. Gather and Review Project Documents

Start by collecting all relevant documentation, architectural, structural, and MEP drawings, as well as specifications and schedules. Ensure that you're working with the latest revisions to prevent measurement errors or scope duplication. Any missing or outdated sheets should be flagged before proceeding.

2. Identify and List Required Materials

Break the project into phases or trade scopes (e.g., structural works, finishes, MEP). Within each phase, list all required materials. Categorize them logically, such as:

-

Concrete (e.g., C30/37 ready mix)

-

Masonry (e.g., hollow blocks, mortar)

-

Wood framing (e.g., 2x4 treated lumber)

-

Finishes (e.g., floor tile, emulsion paint)

-

Fixtures (e.g., light fittings, plumbing valves)

Be specific in naming materials, avoid vague entries like "tile" or "cable."

3. Define Units of Measurement

Assign a standardized unit of measure for each material. These should align with how suppliers quote their products and how your procurement team will place orders.

-

Concrete: cubic meters (m³)

-

Drywall or flooring: square meters (m²)

-

Pipes or conduits: linear meters (lm)

-

Fixtures or fittings: number of units (pcs)

Maintaining consistency in units helps prevent confusion during ordering or cost calculation.

4. Take Measurements from Plans

Use the drawings to extract measurements either manually or using takeoff software.

-

For printed drawings. Use a scale ruler to measure lengths, areas, or volumes.

-

For digital takeoffs. Use tools that allow you to select regions, draw polygons, or identify symbols for automated counts.

Apply the correct measurement method (count, area, volume, or length) based on the material type.

5. Calculate Material Quantities

Once measurements are taken, convert them into quantities using appropriate formulas. For example:

-

Wall paint. Area = height × width × number of coats

-

Concrete slab. Volume = length × width × depth

-

Tiles. Net area + 10% waste for cuts and breakage

Include a waste factor where necessary, typically 5–10% depending on the material and installation conditions.

6. Input Data into the Takeoff Sheet

Enter the data in a structured format that includes:

-

Material description

-

Quantity

-

Unit of measure

-

Unit rate (optional at this stage)

-

Total quantity or cost

-

Notes (e.g., location, remarks, or source of measurement)

Use consistent column headers and formatting across sheets. Group materials by trade or work section to keep the sheet organized.

7. Review and Cross-Check the Sheet

Spot-check all major or high-cost items against the drawings. Ensure that nothing critical has been missed, especially structural or embedded elements that may not be visible on all views.

If possible, involve another estimator or a project engineer to review the takeoff sheet. Peer review helps catch overlooked components and validates assumptions before quantities are passed downstream.

8. Update the Sheet as the Project Evolves

Design revisions, scope changes, or RFIs (Requests for Information) may alter material needs. Keep the takeoff sheet updated in real time and highlight any modified entries.

Ensure that changes are communicated clearly to procurement, execution, and client-facing teams to avoid mismatches in scope or delays in delivery.

Maintaining a live, version-controlled takeoff sheet ensures that it remains a reliable reference throughout the project lifecycle.

Eliminate procurement errors

Request a demo

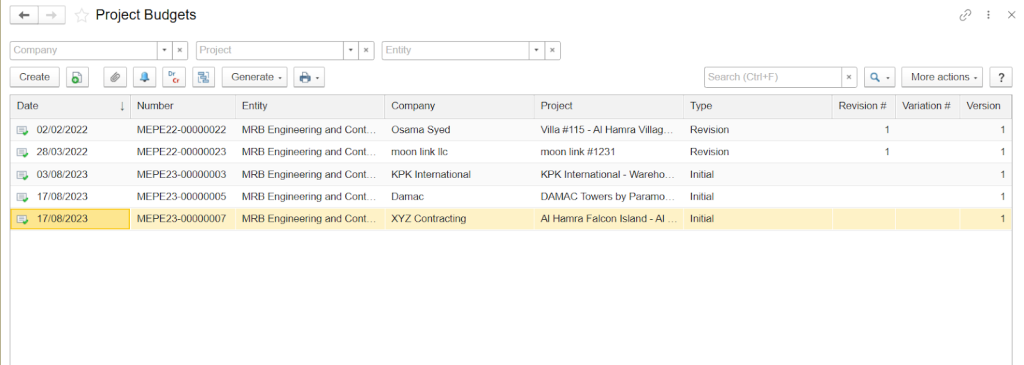

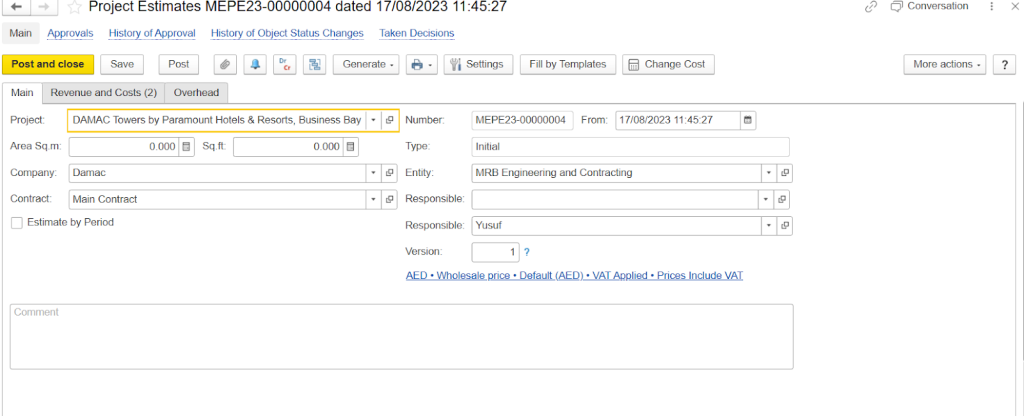

Using FirstBit ERP for Construction Takeoff and Estimation

For companies managing multiple construction projects or dealing with detailed material tracking, having a structured workflow that integrates takeoff data into estimation and costing systems is essential. FirstBit ERP is designed to support this exact need with built-in tools that bring visibility and consistency to preconstruction planning.

Through its

project costing module,

FirstBit ERP allows users to upload Bills of Quantities (BOQs) and link them directly to budgeting, procurement, and project tracking functions. Once uploaded, line items can be categorized by Work Breakdown Structures (WBS), assigned material or labor costs, and monitored through execution phases, ensuring that every quantity is traceable from initial takeoff to final billing.

The system also provides the following:

Project Budgets in FirstBit ERP

Automated Project Cost Estimation in FirstBit ERP

-

Integration with procurement workflows ensures that material quantities and cost limits are synced with supplier orders.

-

Progress tracking against BOQ line items offers a real-time view of physical vs. financial progress

For firms that still rely on manual sheets or disconnected tools, transitioning to FirstBit ERP allows for a more centralized and transparent workflow, especially for teams dealing with high-volume tenders, repeatable project formats, or strict client reporting requirements.

Conclusion

Construction takeoffs aren’t just about measuring materials; they’re about building a reliable foundation for every decision that follows. From the first quantity to the final cost, the quality of your takeoff process determines how smoothly your project runs, how accurate your bids are, and how confidently your team executes.

Whether you're using spreadsheets or enterprise systems, the goal remains the same: clarity, accuracy, and control. And as project complexity grows, so does the need for systems that make those outcomes easier to achieve, not harder.

Takeoff is no longer a side task; it's a strategic advantage. The teams that treat it that way are already ahead.

Align every purchase with project goals

Track supplier performance and control costs

Request a demo

FAQ

1. Is there a standard format or template for a construction takeoff?

There’s no universal standard, but most companies use spreadsheets or estimating software. Templates typically include columns for item description, quantity, unit, unit cost, total cost, and notes. What matters most is consistency and clarity across all rows.

2. What’s the difference between a takeoff for residential vs. commercial construction?

Residential takeoffs are generally simpler, covering fewer trades and materials. Commercial projects require greater detail, covering complex systems like HVAC, fire protection, and structural steel, with higher volume and coordination.

3. How often should takeoff data be updated during a project?

Takeoffs should be updated whenever there’s a design revision, a change in scope, supplier pricing updates, or delivery delays. Keeping them current helps avoid procurement mistakes and schedule disruptions.

4. How do construction takeoffs tie into procurement and scheduling?

Takeoff quantities inform what materials need to be ordered and when. This directly affects procurement timelines and helps the scheduling team align deliveries with the construction sequence.

5. Can construction takeoffs include contingency or buffer quantities?

Yes. Estimators typically add a small buffer (usually 5–10%) to account for waste, design changes, or minor errors. These allowances should be explicitly stated in the sheet to maintain transparency.

Umme Aimon Shabbir

Editor at First Bit

Aimon brings a deep understanding of the modern construction business to her articles by providing practical content.