What happens when a project runs over budget — who pays the price?

For many owners and contractors, the answer sparks disputes, delays, and strained relationships. With material prices climbing and supply chain disruptions becoming more common, these budget risks are only growing. Owners and contractors need contract models that protect finances without slowing projects down.

That’s why many turn to Guaranteed Maximum Price (GMP) contracts — a model that caps total cost for the owner while covering actual expenses for the contractor.

This article breaks down how GMP contracts work, when to use them, and how they help balance risk, control, and flexibility on complex projects.

What Is a GMP Contract in Construction?

A Guaranteed Maximum Price (GMP) contract is a cost-reimbursement agreement that sets a ceiling price for construction projects. Under this arrangement, the contractor commits to completing the work within the established maximum price, while the owner pays actual project costs as they occur.

The main goal of a GMP contract is to give owners budget certainty while allowing contractors the flexibility to handle project challenges effectively. Unlike standard fixed-price contracts, GMP agreements provide transparent cost visibility and opportunities for shared savings when projects finish under budget.

Here's what defines GMP contracts:

The fundamental purpose is to balance risk and reward. Owners get protection against cost overruns, while contractors aren't penalized for circumstances outside their control. This creates a collaborative environment where both parties work toward efficient project delivery.

Essential features of GMP contracts include:

-

Maximum price guarantee. The project cost cannot exceed the agreed ceiling (except for approved changes)

-

Actual cost reimbursement. Real expenses plus contractor fees are paid as work progresses

-

Savings sharing. When costs come in below the GMP, both parties benefit from the difference

-

Transparent accounting. Owners receive regular, itemized reports detailing actual labor, material, and subcontractor costs, giving them full visibility into how funds are spent throughout the project

-

Contingency provisions. Built-in allowances for unforeseen circumstances and changes

This contract structure works particularly well for complex projects where traditional fixed-price arrangements might be too rigid or cost-plus contracts too risky for owners.

Risk Management Mechanisms for GMP Contract Projects

An empirical survey of industry practitioners in Hong Kong identified the most effective risk mitigation measures for GMP contracts.[?] The five top-ranked individual measures were:

- Proper project team selection

- Mutual trust between contracting parties

- Clearly defined project scope

- Early contractor involvement in design

- Proactive contractor participation throughout the GMP process

What's more, implementing Enterprise Resource Planning (ERP) systems can be a valuable technological risk management tool for GMP projects. Systems such as FirstBit ERP for construction provide real-time budget monitoring and cost control capabilities, helping project teams to keep expenditure within the guaranteed maximum price limits and avoid cost overruns.

Why It's Gaining Popularity in Modern Projects

GMP contracts are experiencing increased adoption in today's construction industry due to several compelling advantages they offer over traditional contracting methods:

-

Early contractor involvement. These agreements frequently enable contractors to join the design process, contributing practical construction knowledge from the project's early stages. This collaborative approach generally leads to more constructible designs and reduces expensive modifications during the building phase.

-

Market volatility protection. With today's unpredictable material prices and workforce challenges, GMP contracts offer protection against market fluctuations while preserving the flexibility needed to respond to evolving conditions.

Research evidence presents mixed outcomes regarding GMP effectiveness. While studies of public water and wastewater facilities demonstrated that GMP contracts exhibited lower cost and time growth compared to lump-sum provisions,[?] other research found cost overruns in 75% of public school projects and 80% of non-school projects in the northwestern United States.[?]

Despite these varied research findings, the combination of cost control, collaboration, and transparency makes GMP contracts particularly appealing for complex construction projects such as hospitals, airports, or mixed-use developments where traditional contract methods may fall short.

Protect your rights under UAE law

Manage contracts efficiently with FirstBit

Request a demo

Key Features That Make GMP Contracts Unique

While every contract type has its place in construction, GMP contracts stand out for their unique ability to balance competing priorities. Here's why more project stakeholders are choosing this approach.

Open-Book Accounting and Financial Transparency

Open-book accounting stands as the most defining characteristic of GMP contracts. This requirement means contractors must maintain complete transparency by providing detailed, real-time access to all project expenses, including:

-

Labor costs and hours worked

-

Material purchases and current pricing

-

Subcontractor invoices and payments

-

Equipment rental and usage costs

-

Administrative and overhead expenses

This level of transparency benefits both parties in meaningful ways. Owners gain comprehensive insight into their investment, allowing for improved cost oversight and strategic decision-making throughout the project. For contractors, this openness demonstrates professional accountability and helps establish trust, frequently resulting in stronger client relationships that extend beyond individual projects.

The open-book structure also enables effective collaborative problem-solving. When budget challenges emerge, both teams can examine the detailed financial records together to develop practical solutions. This partnership approach replaces the adversarial negotiations that often characterize traditional contract relationships, creating a more productive working environment focused on project success rather than blame assignment.

Flexible Yet Structured Scope Management

GMP contracts provide exceptional capability for managing scope changes – one of construction's most complex challenges. This structure enables several key management approaches:

-

Defined change order procedures. Established processes for handling scope modifications ensure that all changes receive proper evaluation and approval before moving forward. This systematic approach prevents unauthorized work and maintains budget control.

-

Contingency fund management. Pre-allocated contingency reserves offer flexibility to address unexpected conditions without immediately requiring contract amendments. These built-in buffers keep projects moving while maintaining financial oversight.

-

Value engineering opportunities. The collaborative framework of GMP contracts promotes continuous value engineering discussions throughout the project. This ongoing dialogue often identifies cost-saving measures while preserving or enhancing project quality.

-

Phased decision making. Complex projects can be structured in phases under GMP contracts, allowing for progressive design development and strategic decision-making as work advances. This approach accommodates evolving project requirements while maintaining cost control.

This flexibility in scope management makes GMP contracts particularly effective for projects where requirements may evolve or where unforeseen conditions are likely to emerge during construction.

What Should Be Included in a Well-Written GMP Contract?

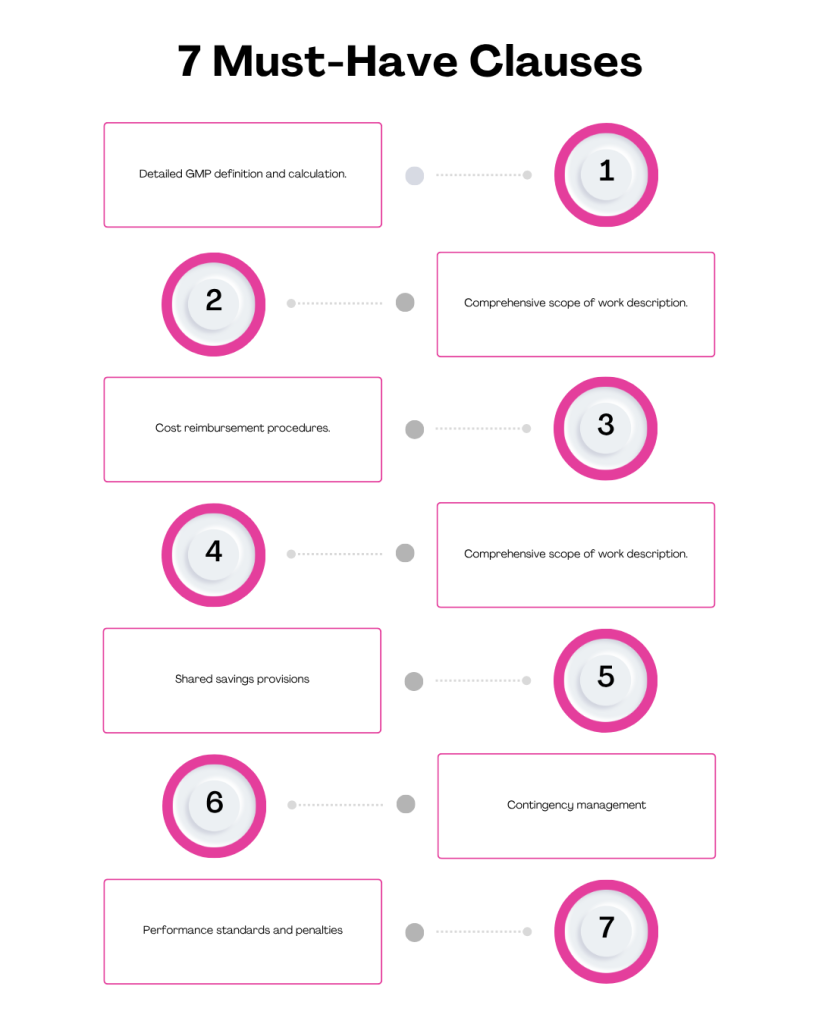

While all contract elements require thorough review, these 7 clauses are essential for successful GMP implementation and should receive focused attention during contract development.

7 Must-Have Clauses

A well-structured GMP contract requires specific clauses to safeguard all stakeholders and promote project success:

- Detailed GMP definition and calculation. Establish precise parameters for what costs fall within the GMP, the calculation methodology, and circumstances that permit modifications. This section should encompass allowances for permits, contingencies, and contractor compensation structures.

- Comprehensive scope of work description. Document the complete work scope, incorporating drawings, specifications, and any assumptions established during GMP development. This detailed foundation prevents disputes over what work is included in the guaranteed price.

- Cost reimbursement procedures. Define systematic processes for cost reporting, documentation standards, and expense approval workflows. Include provisions for regular cost auditing and verification procedures to maintain financial accuracy.

- Shared savings provisions. Specify the distribution method for any savings achieved below the GMP between the owner and contractor. Common arrangements vary from equal 50/50 distributions to more sophisticated tiered sharing structures based on savings levels.

- Change order procedures. Establish clear protocols for managing scope modifications, including their impact on the GMP, required approvals, and documentation standards. These procedures ensure changes are handled consistently and transparently.

- Contingency management. Define contingency fund administration, including control authority and usage criteria. Clear guidelines prevent disputes over when and how these reserves can be accessed.

- Performance standards and penalties. Outline quality expectations, schedule requirements, and consequences for non-performance or contractor-caused GMP overruns. These standards establish accountability while protecting project objectives.

Stay fully compliant with the latest UAE laws and regulations

Request a demo

When and Why Should You Use a GMP Contract?

The specific approach and nature of your construction project will guide the optimal contract structure selection. Here are the scenarios where GMP contracts typically perform best.

Ideal Project Scenarios

GMP contracts prove most effective for specific project types and circumstances:

-

Complex projects with design-build elements. When projects demand extensive coordination between design and construction teams, GMP contracts support collaborative methodologies that typically enhance project outcomes and reduce conflicts.

-

Projects with uncertain conditions. Renovation work, construction in challenging environments, or projects involving subsurface unknowns benefit from GMP flexibility. These contracts allow teams to address unexpected discoveries while maintaining budget oversight.

-

Fast-track construction. When aggressive schedules require construction to begin before design completion, GMP contracts enable work progression while managing financial exposure for both parties.

-

High-value projects. Large-scale projects where cost overruns could create significant financial impact gain valuable protection from the cost certainty that GMP contracts provide.

-

Established owner-contractor relationships. When owners and contractors have successful project histories and seek to build on existing trust and collaboration, GMP contracts can strengthen these partnerships while delivering improved results.

These scenarios highlight situations where GMP contracts' unique combination of cost control and flexibility provides the greatest advantage over traditional contract structures.

Who Benefits Most?

While owners and contractors each have distinct motivations for choosing GMP contracts, the structure creates mutual benefits that align both parties' interests toward successful project delivery.

Owners benefit from GMP contracts when they:

-

Need cost certainty for budgeting and financing

-

Want transparency into project costs

-

Value contractor input during design phases

-

Have complex projects requiring collaborative management

-

Want to share in cost savings

From an owner's perspective, these benefits make GMP contracts attractive for specific project types. Contractors, on the other hand, find GMP contracts advantageous when they can leverage their operational strengths:

Contractors benefit when they:

-

Have strong cost control systems

-

Want to be involved early in project planning

-

Can demonstrate value through innovation

-

Have established relationships with subcontractors

-

Prefer collaborative rather than adversarial project approaches

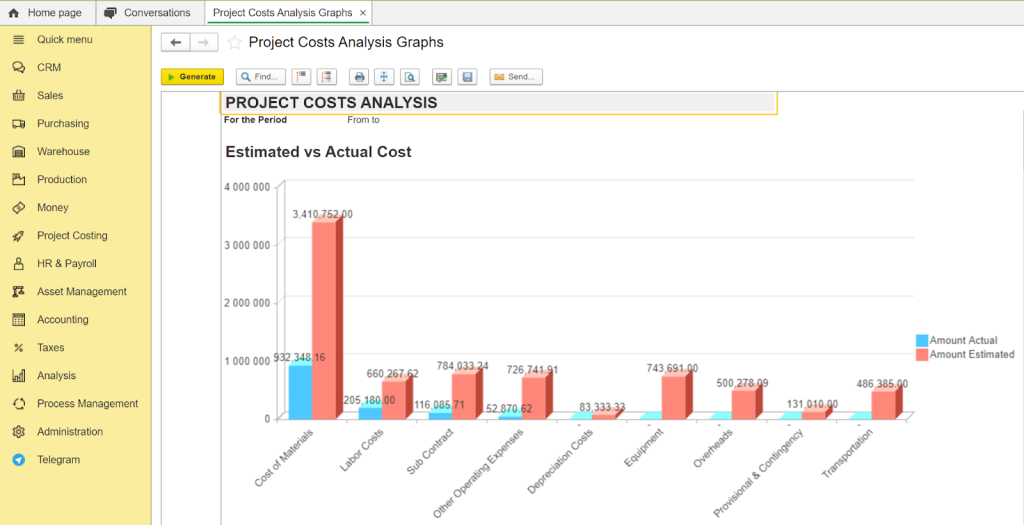

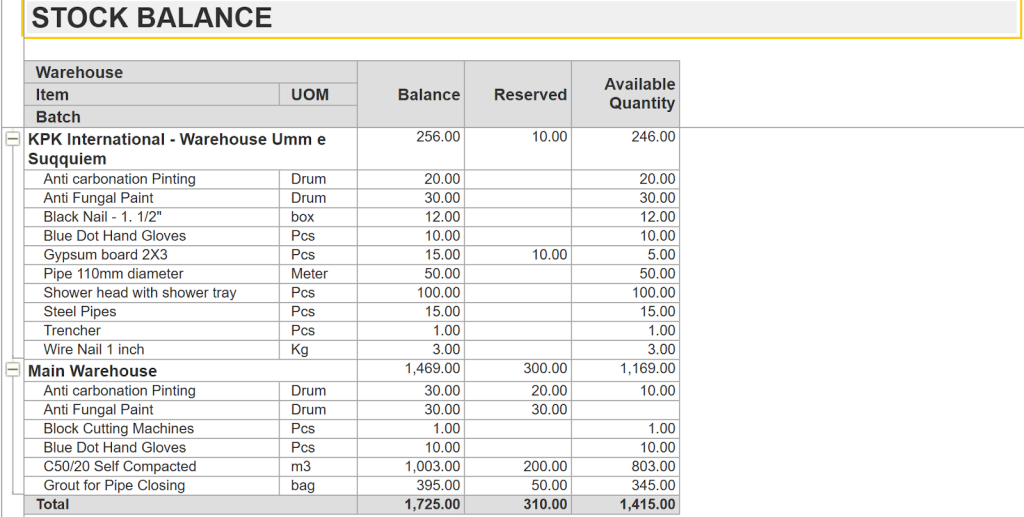

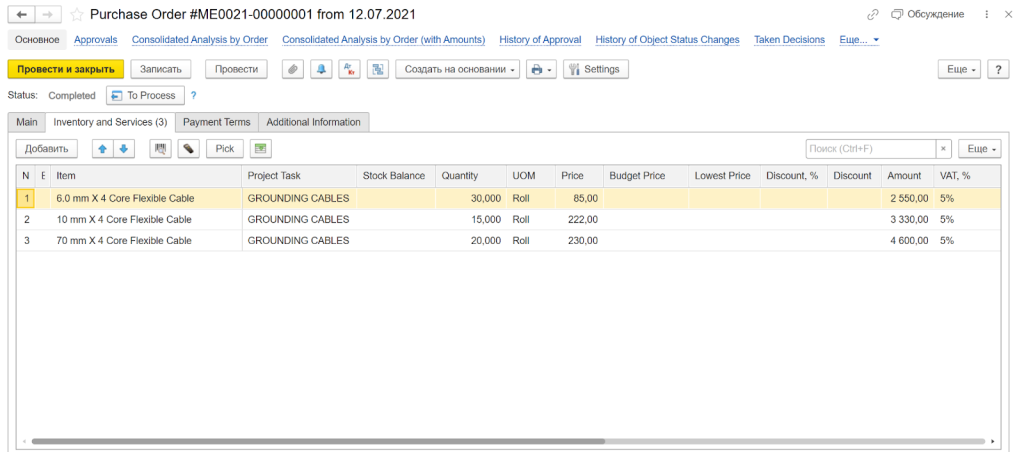

Maintaining cost control and minimizing risk in GMP contracts depends heavily on accurate, up-to-date project data. That’s where digital tools can make a real difference. Platforms like FirstBit ERP support this process by tracking actual costs in real time, organizing documentation, and providing clear, itemized reports — helping both owners and contractors stay aligned and avoid disputes.

How FirstBit ERP Helps You Manage GMP Contracts with Confidence

Effective GMP contract management demands advanced cost monitoring, comprehensive reporting systems, and robust project oversight capabilities. Systems like FirstBit ERP delivers construction companies the essential tools required for successful GMP project execution:

-

Real-time cost tracking. Monitor all project costs in real-time, ensuring accurate reporting and early identification of potential overruns.

-

Automated reporting. Generate detailed cost reports required for open-book accounting without manual data compilation, saving time and improving accuracy.

-

Change order management. Streamline change order processes with automated workflows, approval routing, and GMP impact calculations.

-

Compliance support. Ensure contract compliance with automated alerts, standardized reporting formats, and audit trail maintenance.

ERP tailored to UAE legislation

Navigate UAE construction laws effortlessly

Request a demo

Alternatives to GMP Contracts

If GMP contracts do not align with your project objectives, alternative contracting methods may be more appropriate for your requirements.

Fixed-Price Contracts

Fixed-price contracts establish a set price for a defined scope, transferring most risk to the contractor. Consider this approach when:

-

Project scope is well-defined and unlikely to change

-

Market conditions are stable

-

The owner prefers simplicity over transparency

-

ЗCompetitive bidding is desired

Advantages: Budget certainty, simplified administration, competitive pricing

Disadvantages: Limited flexibility, potential for adversarial relationships, quality risks if pricing is too aggressive

Cost-Plus Contracts

Cost-plus contracts reimburse all legitimate project costs plus a fee, with no maximum price limit. These work well when:

-

Project scope is highly uncertain

-

Innovation and quality are primary concerns

-

The owner wants maximum control over project decisions

-

Emergency or time-critical situations exist

Advantages: Maximum flexibility, high-quality outcomes, no contractor risk premium

Disadvantages: No cost certainty, potential for cost escalation, requires intensive oversight

Time & Materials Contracts

T&M contracts pay for labor at predetermined rates plus material costs. Consider this approach for:

-

Small or short-duration projects

-

Service and maintenance work

-

Projects where the scope cannot be predetermined

-

Emergency response situations

Advantages: Flexibility, appropriate for uncertain scope, simplified administration

Disadvantages: Limited cost control, potential for inefficiency, requires close monitoring

Final Thoughts

GMP contracts aren’t a universal solution —but for projects where cost uncertainty is high and collaboration is essential, they offer a structured way to align owner and contractor interests. Their success depends less on the contract itself and more on how well it’s implemented: with clear expectations, disciplined cost tracking, and mutual trust.

For teams willing to invest in that level of coordination, GMP can be a practical and balanced choice — especially when project complexity makes traditional contract models harder to manage.

Navigate UAE construction laws with an ERP built for the UAE market

Request a demo

Anna Fischer

Construction Content Writer

Related terms

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.