The construction industry today processes 2.5 quintillion bytes of data daily, yet most contractors still struggle to turn this information into actionable insights.

[?] Project delays, budget overruns, and resource allocation issues remain common challenges despite advances in technology and management methods.

Artificial Intelligence is transforming how construction managers handle multiple projects by processing countless variables that traditionally challenged the industry. From predicting weather impacts and optimizing material deliveries to forecasting workforce needs and scheduling equipment maintenance, AI-powered systems are streamlining complex decision-making processes that directly affect project timelines and budgets.

This guide explores how artificial intelligence is offering practical solutions to these everyday challenges. You'll learn about specific AI applications that can help predict project delays, optimize resource allocation, and improve cost estimation accuracy. We'll examine real cases where AI has helped contractors reduce operational costs and complete projects ahead of schedule and provide actionable steps to implement these solutions in your own operations.

Introduction to Artificial Intelligence in Construction

The application of AI spans the entire construction lifecycle, from pre-construction planning through post-completion maintenance. Organizations utilize its computational power and predictive capabilities to optimize design, construction, and maintenance processes. The impact varies from operational efficiencies, such as AI chatbots saving minutes on routine tasks like document retrieval or status updates, to more complex applications and strategic benefits like predictive analytics potentially saving millions through optimized project scheduling.

Industry adoption has been gradual, primarily due to the complex nature of construction projects involving multiple stakeholders, specialists, and suppliers. A company's Artificial Intelligence implementation success depends on three key factors:

-

Financial capacity for technology investment. With this funding strategy, you can secure resources for both initial AI investments and sustain long-term operational needs, including system maintenance, updates, and staff training.

-

Workforce capability. With this skills development approach, you can ensure your workforce possesses the digital competencies and technical expertise needed to effectively utilize AI tools.

-

Organizational readiness for innovation. With this cultural transformation, you can build an environment where technological innovation is welcomed and new operational methods – such as automated document processing, AI-powered scheduling systems, real-time project tracking, digital collaboration platforms, and predictive maintenance protocols – are actively supported.

Key Applications of AI in Construction Management

Every day on the construction site brings dozens of decisions that impact project success – from crew scheduling to equipment deployment. While experience helps, AI systems can now assist even seasoned contractors in processing thousands of variables simultaneously.

1. Project Planning and Scheduling

AI systems analyze data from multiple sources to build realistic schedules of a potential construction project. The process starts with inputting project data, including completed project timelines, delay factors, and team performance metrics.

For instance, a leading Japanese contractor used

ALICE Technologies,

[?] an AI-powered construction simulation platform, to optimize scheduling for a major airport expansion. Traditional scheduling methods struggled with the project's complexity, so ALICE generated millions of potential scenarios, considering factors like labor availability and equipment constraints.

The contractor reduced the project timeline by 10.2% by implementing AI-driven scheduling, resulting in significant cost savings and improved resource utilization. This case highlights how AI can enhance efficiency and adaptability in large-scale construction projects.

Additionally, AI scheduling tools like Briq

[?] and Buildots

[?] use machine learning to track progress and suggest adjustments based on real-time site conditions. When weather changes or equipment failures occur, these systems automatically recalculate dependencies and propose new timelines, helping teams stay on track.

2. Cost Estimation and Budgeting

In tools like Autodesk Construction Cloud, there are several AI-based capabilities that help automate daily workflows including things like auto-tagging in photos, automatically sectioning out a specification, auto-generating a submittal log, or automatically detecting symbols on a drawing for takeoff.

Setting up AI-powered cost estimation begins with providing the system historical bid data. This includes successful and unsuccessful bids, actual project costs, variance reports, etc. The system learns from this data to identify cost patterns and risk factors.

When preparing a new estimate, input the project specifications, and the AI cross-references similar past projects, current material prices, and labor rates to generate detailed cost breakdowns. The system continuously updates its predictions for you as new data becomes available.

3. Resource Management

AI resource management starts with connecting your equipment sensors and inventory systems to a central platform. Then, the Artificial Intelligence analyzes this data to:

-

Track equipment usage patterns and predict maintenance needs 2-3 weeks in advance

-

Monitor material consumption rates and automatically trigger reorder points

-

Compare worker certifications and skills against project requirements

-

Create equipment deployment schedules that minimize transportation and idle time

AI collects pretty much all information and this is where such systems as

FirstBit ERP with inventory management module come in handy. The ERP systems integrate these AI capabilities through a user-friendly dashboard where contractors can view and adjust all resource allocations from a single screen.

Transform your business

Embrace innovation with FirstBit ERP

Request a demo

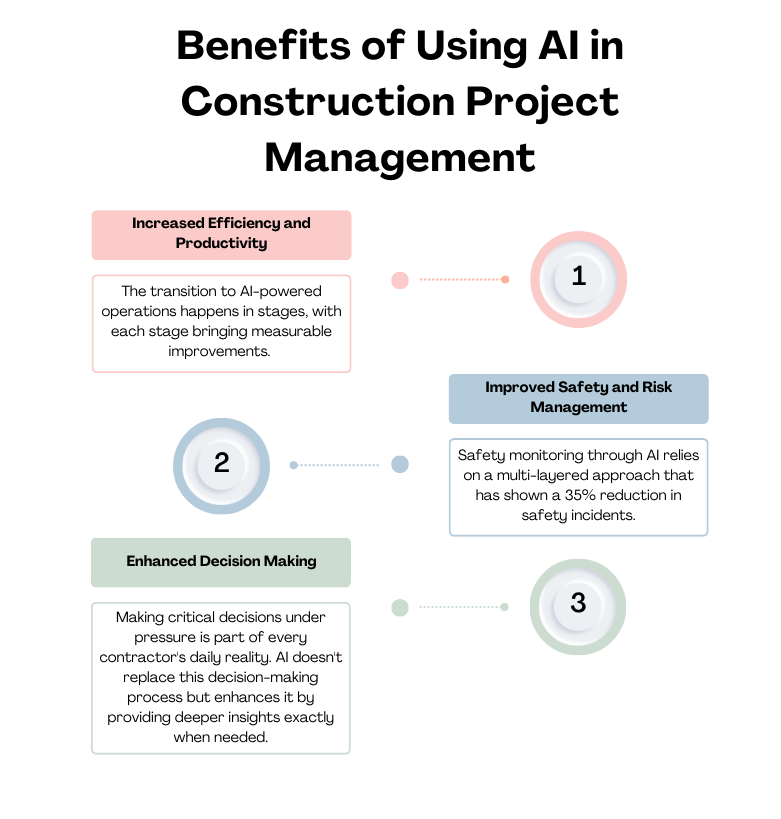

Benefits of Using AI in Construction Project Management

AI implementation in construction reduces project delivery time by 15-20% and overall costs by up to 13%.[?]

These efficiency gains demonstrate why leading contractors are increasingly turning to AI solutions to maintain competitiveness. For contractors facing shrinking margins and increasing project complexity, the practical impacts of Artificial Intelligence implementation directly address daily operational challenges.

1. Increased Efficiency and Productivity

The transition to AI-powered operations happens in stages, with each stage bringing measurable improvements. Construction sites implementing AI-driven workflows report:

This is how you can use AI for efficiency:

-

Integrate AI analytics in BIM (Building Information Model)

-

Set up automated progress monitoring

-

Create AI-powered quality control checkpoints

-

Utilizing drone-based site surveillance and mapping

-

Analyzing historical project data for better cost estimation

2. Improved Safety and Risk Management

Safety monitoring through AI relies on a multi-layered approach that has shown a 35% reduction in safety incidents.

[?] The system, in general, works by:

-

Monitoring site conditions in real-time through IoT sensors

-

Analyzing worker movement patterns to identify high-risk areas

-

Assessing weather-related risks through predictive algorithms

-

Checking safety regulations compliance through automated systems

To enhance construction site safety, start by installing environmental sensors and surveillance cameras throughout the work area. These devices feed data into AI algorithms that continuously monitor for hazardous patterns and potential risks.

In some countries, this is a mandatory requirement for construction companies.

[?] When the system detects unsafe conditions or behaviors, automated alerts immediately notify relevant personnel.

By establishing clear response protocols, your team can quickly address safety concerns before they lead to accidents or injuries, creating a proactive rather than reactive approach to construction site safety.

3. Enhanced Decision Making

Making critical decisions under pressure is part of every contractor's daily reality. Artificial Intelligence doesn't replace this decision-making process but enhances it by providing deeper insights exactly when needed. When facing tough calls about resource allocation or timeline adjustments, having AI-processed data at your fingertips makes the difference between informed decisions and educated guesses.

AI transforms raw data into actionable insights through:

-

Predictive analytics for project delays (accuracy rate 85%)

[?]

-

Risk assessment matrices based on historical data

-

Resource optimization algorithms

-

Real-time cost impact analysis

These systems have demonstrated a 40% improvement in decision accuracy when compared to traditional methods.

FirstBit ERP features an analytics dashboard that consolidates all project data, transforming complex information into clear visualizations and actionable insights for immediate decision-making.

Challenges and Considerations in AI Implementation

Despite the proven benefits, construction companies face several hurdles when adopting AI technologies. Understanding these challenges helps create realistic implementation strategies and set proper expectations.

1. Initial Investment and ROI Concerns

The financial aspect of AI implementation requires careful planning. The initial investment typically starts with software licensing and customization, ranging from $50,000 to $150,000. Additional costs include necessary hardware upgrades, comprehensive staff training programs, and system integration expenses to align with existing operations.

The investment horizon shows promising returns, with most companies achieving ROI within 12-18 months. This return stems from several key improvements:

-

Significant reduction in labor costs for routine tasks

-

Fewer error-related expenses

-

More effective resource utilization

-

Accelerated project delivery times

While the upfront costs require careful consideration, the long-term financial benefits demonstrate clear value for construction operations.

Pro tip: Leverage AI's predictive analytics capabilities to create detailed ROI forecasts for your specific use case. Artificial Intelligence can analyze historical project data to identify areas with the highest potential for cost savings, helping prioritize which features to implement first.

2. Data Quality and Integration Issues

One of the biggest hurdles in AI implementation is ensuring data quality and consistency. Construction sites generate massive amounts of unstructured data from multiple sources – from manual entry forms to IoT sensors and cameras. Without proper collection methods, this data often becomes fragmented, inconsistent, or simply unusable.

Many companies struggle with missing information, duplicate entries, and incompatible data formats across different systems.

Integration presents another major challenge. Most construction firms use various software solutions that don't naturally communicate with each other, creating data silos. Connecting these systems while maintaining data integrity often requires significant technical expertise and resources.

Pro tip: Implement an AI-powered data management platform that automatically standardizes incoming data and flags inconsistencies. These systems can learn from your existing data patterns to establish validation rules and create automated workflows for data cleaning. For integration, use API-based middleware solutions that can act as translators between different software systems, ensuring seamless data flow across your digital ecosystem.

These measures have shown to improve data accuracy by 60% and reduce integration issues by 45%.

3. Training and Adoption

The human factor remains crucial in AI implementation. Successful adoption requires:

-

Structured training programs (3-6 months)

-

Clear communication about AI's role

-

Gradual implementation in phases

-

Regular feedback sessions

Companies that follow these steps report 75% higher user adoption rates and 50% faster implementation times.

Pro tip: Set up a mentorship program where tech-savvy team members guide others through weekly micro-learning sessions. Also you can create a digital knowledge base with recorded solutions to common problems.

FirstBit supports this transition through comprehensive training programs and 24/7 technical support. The company's implementation specialists work directly with construction teams to ensure smooth integration of the ERP system, offering both scheduled training sessions and on-demand assistance.

Choose the right technology for your construction business

Request a demo

Case Studies: AI & Automation in Construction

Real-world implementations demonstrate how AI transforms construction operations from concept to completion. These cases highlight specific outcomes and methodologies that have proven successful, showing how theory translates into practical results on the ground.

Case Study 1: Automated Progress Monitoring at Hudson Yards Development

The Hudson Yards project in New York implemented an AI-powered progress monitoring system utilizing drone technology and computer vision.

[?] The solution processed over 20,000 daily site photos, comparing them against BIM models to track construction progress. This implementation reduced inspection time by 60% and increased accuracy in progress reporting from 80% to 95%. The system identified potential delays before they impacted the schedule, allowing for proactive resource allocation.

Case Study 2: AI Safety Management at Skanska UK

Skanska UK deployed an AI-based safety monitoring system across multiple construction sites.

[?] The system utilized strategically positioned cameras and sensors to detect safety violations and potential hazards in real-time. After six months of implementation, the company reported:

-

30% reduction in safety incidents

-

40% improvement in PPE compliance

-

25% decrease in near-miss incidents

-

Significant reduction in manual safety inspection hours

Future Trends in AI and Construction Project Management

The construction industry stands at the cusp of a technological revolution. While current AI applications are impressive, emerging trends promise even more dramatic changes in how we plan, execute, and manage construction projects.

1. Automation and Robotics

The integration of AI with construction equipment and automation systems is gradually changing how work is performed on construction sites. While traditional methods still dominate the industry, new technological solutions are being tested and implemented at various scales.

Recent developments in autonomous construction equipment show promising results. For example, AI-assisted excavators can now perform basic digging operations with improved precision, though they still require human supervision and intervention.

[?]

-

Work collaboratively with human teams

-

Adapt to changing site conditions in real-time

-

Handle complex tasks like brick laying and welding

-

Operate continuously during off-hours

Perhaps most importantly, these systems learn from each operation. Every project adds to their knowledge base, improving efficiency and accuracy for future work. Construction firms implementing these technologies report productivity gains of up to 45% on repetitive tasks.

2. Smart Construction Sites

The concept of a smart construction site goes far beyond simple automation. It represents a fully connected ecosystem where every element – from materials to machinery to workers – is part of an integrated network of intelligence.

Modern smart sites are implementing:

-

AI-powered surveillance systems that monitor site safety 24/7

-

Environmental sensors that adjust site conditions automatically

-

Digital twin technology that provides real-time project visualization

-

Predictive systems that anticipate and prevent bottlenecks

Predictive systems that anticipate and prevent bottlenecks

The next wave of construction technology is set to bring several practical improvements to project management. Advanced logistics systems will help coordinate material deliveries and site operations more smoothly, while AI-powered quality control will use cameras and sensors to catch issues early.

New tools will also focus on environmental impact, helping projects stay efficient while meeting sustainability standards. These systems will work together to help sites adapt quickly to changing conditions, from weather shifts to supply chain updates, giving you better control over your construction projects.

ERP that saves your money

Adopt FirstBit ERP to cut costs, boost ROI, and effectively plan future cash flows

Request a demo

Frequently Asked Questions About AI in Construction

1. What's the minimum project size where AI implementation makes financial sense?

AI implementation becomes cost-effective for contractors managing projects above $5 million annually. According to studies, the initial investment ($50,000-150,000) typically pays for itself within 12-18 months through reduced errors, better resource management, and improved productivity.

2. How long does it take to get teams up to speed with AI tools?

Basic Artificial Intelligence tool proficiency usually takes 2-3 weeks of hands-on training. Full integration into daily workflows typically requires 3-6 months, with most teams reaching optimal efficiency after completing one full project cycle using the new systems.

3. How does AI handle unexpected changes or delays in construction projects?

AI systems continuously learn from project data, adapting their predictions and recommendations based on real-time information. When changes occur, the system recalculates schedules, resources, and cost impacts within minutes, providing multiple alternative solutions based on historical project data and current constraints.

Anna Fischer

Construction Content Writer

Anna has background in IT companies and has written numerous articles on technology topics.