In the construction industry, where precision and coordination drive success, delays remain a persistent challenge. Rarely do these setbacks arise from singular, catastrophic events; instead, they stem from a series of interconnected inefficiencies that cascade across a project. For instance, a delayed material delivery can halt a framing crew, subsequently postponing electrical work and derailing the entire project schedule.

With data indicating that large-scale construction projects frequently exceed timelines by 20% and budgets by up to 80%, effective time management is critical to achieving on-time and on-budget delivery[?].

This article presents proven strategies, advanced tools, and actionable insights to optimize project efficiency, enabling professionals to transition from reactive problem-solving to strategic, proactive control over project timelines.

Time Management in Construction: What Is It

Time management in construction involves strategically organizing schedules, labor, materials, and stakeholder coordination to ensure efficient project progress and timely completion. This critical process mitigates delays and drives on-schedule, on-budget delivery of complex projects. This requires a systematic approach that anticipates potential challenges and ensures each task contributes to the project's overall goals.

Modern construction teams leverage specialized tools and strategies to optimize workflow and maintain project momentum. From advanced software platforms to clear communication protocols, successful time management combines technological innovation with strategic planning.

How Time Management Impacts Project Success

Time management in construction drives project outcomes by coordinating schedules, labor, materials, and stakeholders. Precise scheduling reduces risks by preempting delays like supply chain issues, controlling costs. Streamlined trade handoffs, such as from framing to electrical, minimize downtime, ensuring workflow efficiency. Aligned tasks and documentation accelerate approvals, advancing milestones.

It’s more than simply adhering to a schedule — it’s a strategic process that influences team dynamics, client satisfaction, and overall outcomes.

Key Benefits of Effective Time Management

Effective time management practices result in:

-

Enhanced team synergy. Foster team unity through structured communication, achieved by establishing routines such as daily stand-ups and utilizing collaborative tools such as Slack or Microsoft Teams.

-

Greater project agility and alignment. Keep teams aligned and responsive to change through clear timelines and strategic resource allocation, visualized with project management software and Gantt charts.

-

Stronger financial control. Prevent cost overruns and protect your budget with proactive planning, supported by detailed financial forecasts and regular cost tracking to identify issues early.

-

Increased operational efficiency. Minimize delays and costly rework through disciplined execution, driven by standardized processes and regular audits that eliminate bottlenecks.

-

Consistent, high-quality outcomes. Maintain high standards from start to finish by establishing clear quality metrics, robust feedback channels, and regular performance reviews.

Consequences of Poor Time Management

Conversely, inadequate time management creates a cascade of negative consequences.

-

Progress impact. A delay in delivering steel beams, for example, can push back framing by weeks, frustrating clients and damaging your reputation.

-

Cost overruns. Reactive responses and inefficiencies — such as unplanned overtime or redundant tasks — consistently drive up costs, often exceeding the original budget.

-

Quality issues. Lower quality work and dissatisfied clients are common results of poor planning, leading to rework, material waste, and ultimately, reduced profitability.

-

Team conflict. Poor time management frequently causes conflict between teams, harming morale and ultimately leading to project overruns, highlighting the need for a structured and proactive approach.

Achieve peak productivity on site

Manage teams, equipment, and materials in FirstBit

Request a demo

Common Time Management Challenges in Construction

Construction projects are complex ecosystems where time management can quickly unravel. Understanding the most frequent obstacles is the first step in developing robust strategies to overcome them:

5 time management challenges in construction

1. Unclear Project Objectives

When project goals lack clarity, teams can misinterpret priorities, leading to wasted effort. For example, if a client requests a "modern office building" without specifying the number of floors or design standards, architects might draft a glass-heavy structure while contractors prepare for a brick facade, causing rework and timeline setbacks.

2. Ineffective Scheduling and Planning

Poorly designed schedules disrupt workflows by ignoring task dependencies or resource availability. Imagine scheduling the drywall installers to arrive before the plumbing and electrical inspections are complete. The result is a paid crew sitting idle, a project thrown off schedule, and a chain reaction of delays for the painters and flooring teams to follow.

3. Poor Communication Between Teams

Miscommunication between teams, like architects and subcontractors, can stall progress. Picture electricians installing wiring based on an outdated blueprint because the design team failed to share updates, resulting in rework that delays other trades.

4. Underutilized Resources

Poor

equipment management inflates costs and slows projects. For example, a rented crane sits unused for days because site preparation lags, racking up expenses without advancing the build.

5. Lack of Real-Time Visibility

Without up-to-date information, managers can’t efficiently adapt to sudden changes, such as weather disruptions or supply issues. For example, imagine a supervisor assigning tasks based on outdated reports without knowing that an excavation unexpectedly hit bedrock, triggering a series of delays.

Maintaining that level of coordination requires real-time visibility across the entire project. This is where modern management tools are essential, giving managers the actionable data they need to navigate challenges on the fly.

An ERP system like FirstBit, for example, provides this live insight, allowing teams to respond swiftly and maintain project momentum without missing a beat.

Best Time Management Strategies in Construction

To achieve project efficiency, focus on these critical strategies:

Set Clear Project Goals

Every successful project starts with a clear destination. When your entire team — from the site supervisor to the newest crew member — understands the specific goals for the week, the month, and the overall project, they can align their efforts and focus on what truly matters, preventing wasted motion and keeping the project on track.

Pro tip

Define deliverables, KPIs, and timelines for each phase to align the team.

Use project management software to create a clear, visual workflow. This allows you to track tasks in real time as they move from one stage to the next, giving you instant oversight and simplifying project management.

Create a Detailed Outline

With your goals set, it's time to draw the map.

Pro tip

Use a Work Breakdown Structure (WBS) to map tasks and dependencies.

Effective planning begins by translating your high-level goals into an actionable roadmap. This goes beyond a simple to-do list; it means defining the full project scope, breaking down large objectives into manageable tasks, and anticipating risks before they can disrupt your timeline.

A critical part of this process is paying close attention to task dependencies — the sequence in which tasks must be completed[?]. You can’t install plumbing fixtures until the drywall is up, and you can’t hang drywall before the electrical and in-wall plumbing are inspected.

Mismanaging these dependencies is a primary cause of on-site delays. This is precisely why modern tools are essential.

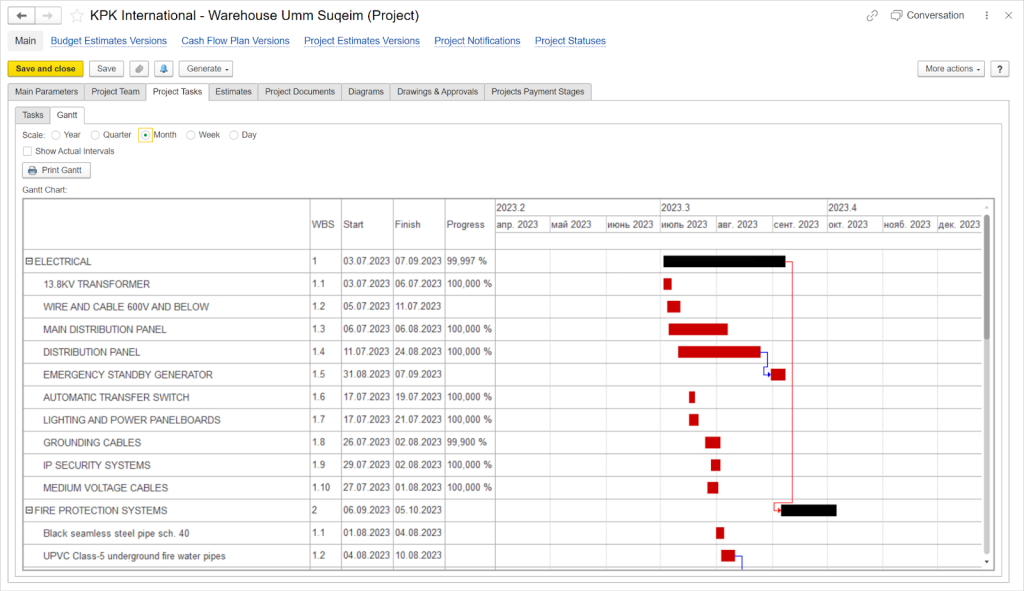

For example, FirstBit’s integrated Gantt charts allow you to visually map out these complex relationships, ensuring that tasks are scheduled in the correct order and that a delay in one area automatically flags potential impacts down the line.

Streamline Communication to Prevent Delays

Poor communication is the friction that grinds a project to a halt. To keep things moving smoothly, establish and enforce clear communication channels.

Pro tip

Hold daily huddles and use digital tools for real-time updates.

Regular, transparent updates for all stakeholders — including clients, subcontractors, and suppliers — ensure everyone is on the same page, preventing the misunderstandings and misalignments that lead to costly rework and delays.

Build and Maintain a Comprehensive Project Schedule

Your project schedule should not be a static document created once and filed away. In construction, it must be a living, breathing tool that adapts to changing conditions on the ground. Weather, supply chain disruptions, and unexpected site conditions are inevitable.

Pro tip

Build a flexible project schedule using digital tools like Primavera or MS Project. Set clear timelines, track progress, and quickly adjust your plan as challenges emerge, ensuring your project remains on course despite unexpected changes.

Systems like FirstBit are invaluable here, helping you track project progress against deadlines in real-time and make data-driven adjustments on the fly to keep the project moving forward.

Allocate Labor and Equipment Based on Demand

Having a crew stand around waiting for a cement mixer or sending machinery to a site before it’s needed are both expensive wastes of time.

Pro tip

Map out project phases in advance and strategically allocate resources. Schedule labor, tools, and equipment exactly where and when they're needed most, minimizing downtime and maximizing productivity. Use project management software to visualize and optimize resource distribution.

Teach Your Team Time Management Skills

Time management shouldn't just be a concern for the project manager. When you empower your entire crew with time management knowledge, you create a culture of efficiency.

Provide formal training on best practices and encourage your foremen and team leads to develop their on-the-spot problem-solving skills. An empowered crew that understands the schedule and their role in it is more likely to identify and resolve minor issues themselves before they escalate into major delays.

Collect Accurate Data During the Project

To find and eliminate your biggest time sinks, you first need to measure where every hour is spent.

Pro tip

Use construction management software to track project data and key performance indicators like labor productivity, resource utilization, and daily worker hours. Set up alerts to quickly identify and address tasks falling behind schedule, enabling immediate corrective actions.

A centralized dashboard gives you an instant, accurate picture of your project’s health. A system like FirstBit ERP, for example, consolidates all key metrics in one place, helping you make timely adjustments to stay perfectly aligned with your goals.

Resolve On-Site Issues Quickly

No matter how well you plan, disruptions are a fact of life on a construction site. The difference between a minor hiccup and a major delay is how fast you can react. The key isn't just hoping for the best, but establishing a clear playbook for when things go wrong.

Pro tip

Develop clear, pre-defined procedures for each team member's role and emergency responses. Create a protocol handbook that outlines exact steps for common on-site challenges, enabling quick and decisive action when issues arise.

Here’s what that looks like in action:

-

For a minor snag, like a misplaced tool, the action chain is simple: a worker informs their foreman, who resolves it directly.

-

For a major subcontractor or material issue, the chain is clear: the foreman escalates to the site superintendent, who coordinates with the project manager for a decision that protects the budget and schedule.

-

For a conflict in the blueprints, the process is formal: the project manager submits a

Request for Information (RFI) to the architect, ensuring the solution is documented and approved.

-

For immediate safety hazards, empower every worker with a "Stop Work Authority" to halt the task instantly and alert their supervisor

[?].

Analyze Project Data to Identify Efficiency Gaps

Regularly review your key performance indicators (KPIs) throughout the project lifecycle. Are your framing crews consistently taking 10% longer than estimated? Is a specific piece of rental equipment sitting idle more often than not?

Pro tip

Compare your planned progress against actual performance weekly using project management dashboards. Quickly identify efficiency gaps and take immediate action: adjust workflows, reallocate resources, or provide targeted support to keep the project on track.

Then, when the project is complete, you can conduct a final, comprehensive review. A thorough post-mortem using all the project data will help you uncover larger, systemic bottlenecks. The insights you gain from both the ongoing and final analysis become the foundation for more accurate bids, tighter schedules, and greater profitability on every job that follows.

Boost project performance

Request a demo

How FirstBit helps Master Your Project Schedule

FirstBit ERP is designed to be the central nervous system for your construction projects, turning time management strategies into reality.

With mobile access, your field team can instantly pull up the correct version on a tablet, eliminating costly rework from outdated plans and ensuring everyone works from the same page.

It provides a single, unified platform that addresses the industry's biggest time-wasters, tackling the miscommunication, material delays, and scheduling errors that derail timelines and budgets.

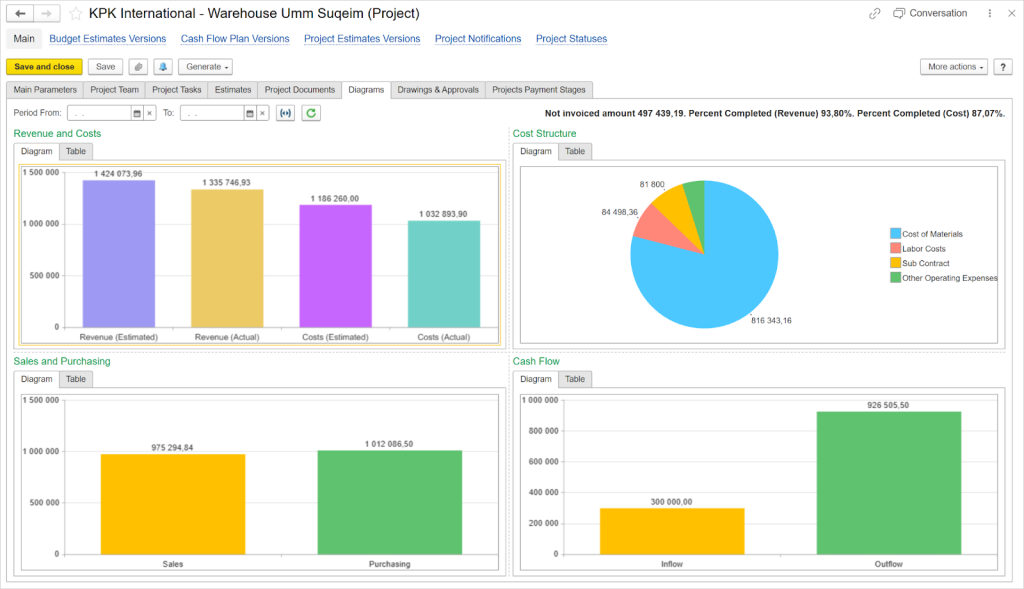

The platform gives you a real-time view of project health, eliminating guesswork. With customizable dashboards and Gantt charts, you can track your most important KPIs and tasks in one place. Here, you can see accurate data as it happens and make preemptive adjustments to keep the project on schedule.

Project diagrams in FirstBit ERP

Gantt charts in FirstBit ERP

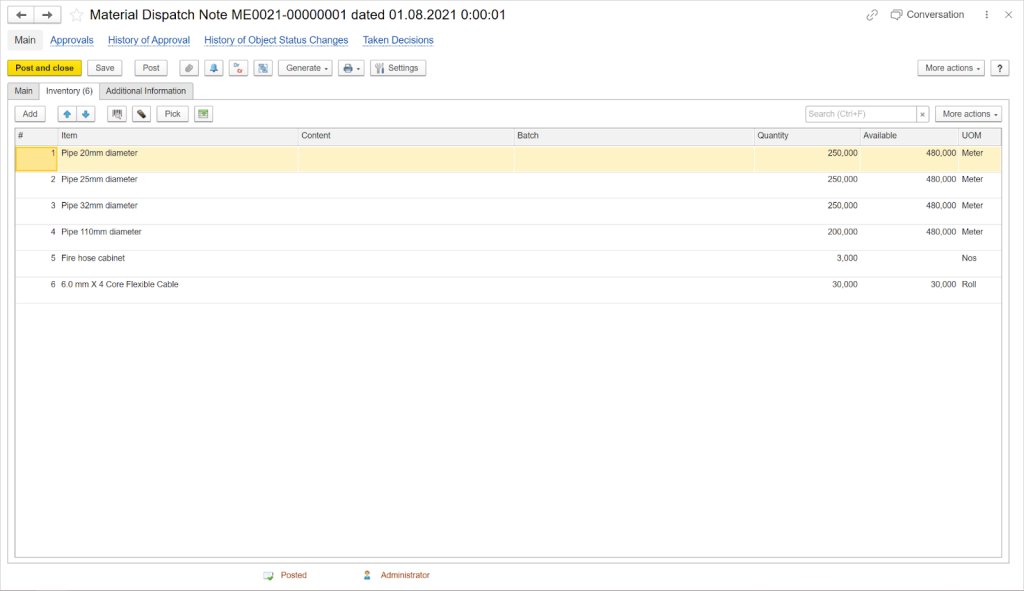

FirstBit’s

inventory management module enhances time management by systematically preventing the single biggest cause of on-site delays: material-related issues. It does this by linking your project schedule directly to your material flow.

Material dispatch note in FirstBit ERP

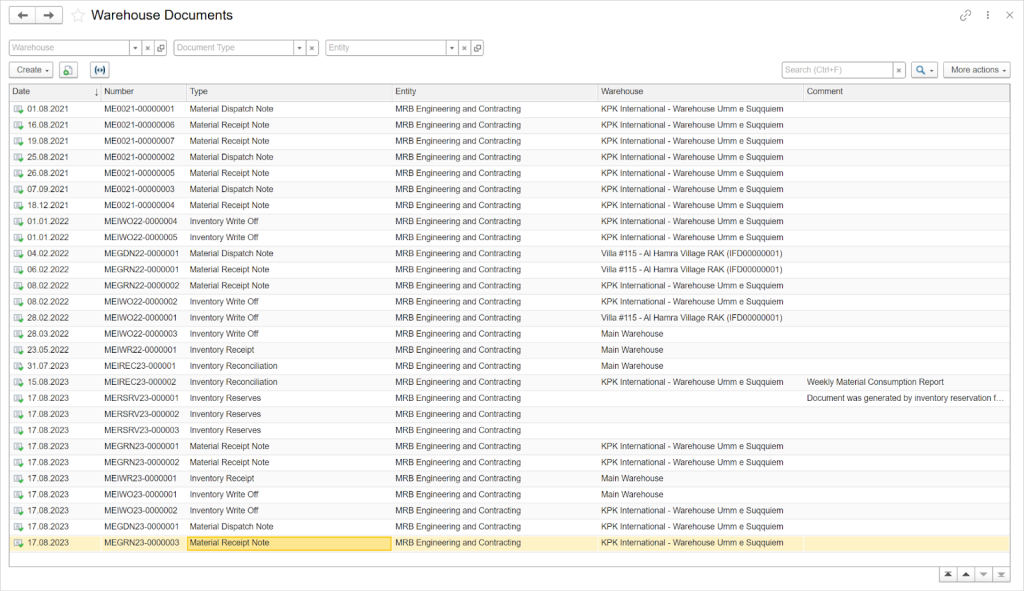

FirstBit puts all your project documents — from the latest blueprints to RFIs and warehouse documents — in one central hub.

Warehouse documents in FirstBit ERP

FirstBit connects every part of your project, from start to finish. This gives you control over your schedule and helps you deliver jobs on time and budget.

Final Thoughts

Mastering time management in construction requires a fundamental shift from reactive firefighting to forward-thinking orchestration. It’s about building a reputation for reliability and precision that extends far beyond a single project's timeline.

Investing in integrated tools like FirstBit ERP is central to this evolution. They provide the foresight needed to meet today's deadlines while building a foundation for continuous improvement. Ultimately, this proactive approach is what fosters deep client trust and paves the way for sustainable success in an increasingly competitive field.

Achieve flawless teamwork

Coordinate roles and schedules through FirstBit ERP

Request a demo

F.A.Q.

1. How can construction managers create realistic project schedules?

To create an effective schedule, break the project down into smaller tasks and estimate how long each will take based on past job data. Always pad the timeline for risks like rain or late deliveries.

For example, add a few extra days for window installations on a high-rise since suppliers often run late. Get input from subcontractors upfront to determine realistic durations, and check in weekly to adjust the plan as the project evolves.

2. How can construction management software streamline time management?

Construction management software is useful for keeping everyone in the loop with real-time updates. Tools like FirstBit ERP allow you to track tasks, hours, and delays in real time.

For instance, if drywall materials are stuck in transit, you will know before the crew shows up empty-handed. This reduces downtime and keeps the team aligned, unlike old-fashioned paper logs that might not be updated for days.

3. How does automation reduce time wastage on construction sites?

Automation minimizes repetitive tasks and errors, saving time across operations. For example, automated drones can survey a site in hours, providing precise measurements that would take a team days to complete manually.

Similarly, automated scheduling tools can instantly adjust timelines when a task runs over, preventing cascading delays without human intervention.

4. What role does resource allocation play in time management for construction?

Effective resource allocation ensures labor, equipment, and materials are available exactly when needed, avoiding idle time.

For example, The Shard’s construction, completed on time in 2012, demonstrates effective resource allocation by scheduling concrete pours with adequate workers and mixers, preventing idle time and delays.[?] Strategic mapping of resources to critical tasks ensured smooth trade handoffs and prioritized high-impact activities, keeping the £435 million project on track.

Anna Fischer

Construction Content Writer

Anna has background in IT companies and has written numerous articles on technology topics.