What if you could monitor every aspect of your construction site—from structural integrity and equipment usage to project progress—in real time, without ever needing to visit the location? Digital twin technology in construction makes this possible.

In today’s fast-paced world, delays, miscommunication, and rework can cost projects thousands—sometimes millions. To stay competitive, leading construction firms are adopting digital twins: real-time, data-driven virtual replicas of buildings and infrastructure.

In this article, you’ll learn about the benefits of digital twin in construction, how digital twin technology is different from BM, and why it can improve the outcomes of your construction project. You’ll also find out about potential challenges you can face while adopting a digital twin in building construction.

What Is a Digital Twin in Construction?

A digital twin in construction is a dynamic, real-time virtual replica of a physical building or infrastructure system. Unlike static 3D models, digital twins continuously update by integrating data from IoT sensors, Building Information Modeling (BIM), cloud platforms, and AI algorithms.

Digital twin technology simulates how a construction project performs throughout its lifecycle: from planning to post-completion maintenance. By reflecting real-world conditions in real time, digital twins help project managers visualize outcomes, reduce errors, and make smarter decisions.

Now that we’ve defined what a digital twin is, let’s explore how it differs from BIM, a concept many teams already use during preconstruction.

How Digital Twin in Construction Differs From BIM

At first glance, a digital twin in construction and BIM may appear similar: both involve 3D representations of construction projects. But their roles are distinct.

BIM is a static model primarily used during the design and preconstruction phases. It’s excellent for coordination among architects, engineers, and contractors, but doesn’t evolve once the building is constructed. While BIM serves as a key data input for any Digital Twin, it alone cannot answer the operational questions facility managers may have about optimizing building operations.

Digital twin technology in construction is dynamic. It’s built on top of BIM but enhanced with real-time data feeds from sensors, smart devices, and ERP systems. This constant feedback loop turns the digital twin model into a living simulation of the building’s current state, making it useful for ongoing operations, performance tracking, and predictive maintenance.

A compelling example of this contrast is the Elizabeth Line project in London. Crossrail, the organization behind it, initially implemented a hybrid digital model that began as a BIM-based “virtual version”. Then it evolved into a digital twin by incorporating real-time data integration and operational coordination[?].

Where a BIM constructs and designs, a twin manages and maintains; like a real-life asset, it never stops being affected by what’s around it.

Malcolm Taylor

Crossrail’s head of technical information

Transform your business

Embrace innovation with FirstBit ERP

Request a demo

Top Benefits of Digital Twin Technology in Construction

The construction industry has always relied on blueprints, spreadsheets, and static models to guide projects. But as buildings and infrastructure become more complex, so do the challenges of managing them efficiently. That’s where digital twin technology in construction comes in.

By creating a continuously updated, virtual version of a construction site or asset, digital twins provide unparalleled visibility, control, and predictive insight. They also improve productivity, accuracy, and stakeholder confidence across construction projects of all sizes.

Let’s look at how this technology is reshaping real-world construction outcomes across every phase of a project.

Enhanced Visualization

Digital twins offer immersive, interactive 3D models that go far beyond traditional blueprints or BIM visuals.

Using VR or AR headsets, stakeholders can walk through a virtual construction site to identify accessibility issues or layout inefficiencies before a single wall is built.

Increased Efficiency and Reduced Rework

Rework is one of the most expensive issues in construction. Digital twins help minimize it by:

-

Printing accurate on-site layouts

-

Detecting design issues before execution

-

Enabling remote monitoring for early problem detection

Reducing rework doesn’t just save time; it also enhances cash flow management and payment accuracy.

Real-Time Asset Tracking and Site Progress

Digital twins integrate with GPS trackers, RFID tags, and IoT sensors. Because of this, they can track the movement of equipment, materials, and workers across the site.

This is what this visibility does:

-

Improves site logistics

-

Prevents bottlenecks

-

Enhances worker safety

-

Enables better forecasting

Stronger Handover Documentation

Digital twins simplify project closeout by uniting all asset details in a single virtual model.

Among them are:

-

Asset tags

-

Serial numbers

-

Warranty data

-

Mechanical/electrical/plumbing (MEP) layouts

This ensures easy access to complete documentation in one convenient location.

Facilities management teams can step into their role with confidence, using a fully informed virtual twin for ongoing maintenance and optimization.

How Digital Twins Improve Construction Outcomes

Digital twins aren’t just technical add-ons; they create measurable results across every phase of construction.

Planning and Design Optimization

By simulating multiple design scenarios, digital twins allow project teams to:

-

Test energy performance. This includes HVAC behavior, thermal dynamics, and building envelope impact. This helps reduce consumption and enhance sustainability.

-

Evaluate structural integrity. Digital twins use virtual stress and load testing to ensure safety before construction begins.

-

Predict traffic flow or HVAC efficiency. DT can do it through simulations of mobility patterns, ventilation systems, and environmental conditions.

-

Optimize material usage. Digital twins help you compare building materials, delivery plans, and layout alternatives. This minimizes waste and cost.

Real‑Time Project Monitoring

Digital twins offer construction teams a continuously updated, real-time overview of site activity and performance.

This is how they do it:

- Live data. First, IoT sensors are embedded into concrete, equipment, and structures. These sensors continuously capture measurements such as structural loads, temperatures, humidity levels, and power usage. The digital twin receives and integrates this information in real time, ensuring its virtual model always accurately reflects the actual site.

- Drone and LiDAR imaging. Aerial drones and laser scanners generate high-resolution orthophotos, as well as 3D point cloud models. They are sent to the digital twin. It uses this data to come up with real-world status updates.

- Safety alerts. When sensor data deviates from expected norms, the system flags potential issues early, before they escalate into structural problems or safety risks.

- Predictive insights with analytics. Integrated AI analyzes triggered sensor and imaging data. Then, depending on the result, it forecasts equipment failures, environmental risks, or workflow bottlenecks.

- Remote oversight. Team members—including off-site stakeholders—can review dashboards, annotated models, and project status via the digital twin. It eliminates the need for constant on-site presence.

You can flag risks early using real-time feedback from your digital twin, avoiding costly repairs or delays.

Improved Collaboration and Decision-Making

One of the major challenges in construction is fragmented communication. With digital twins:

-

Everyone, from architects to electricians, works from the same real-time model

-

RFIs (Requests for Information) are reduced

-

Errors are caught early

-

Decision-making becomes faster and more informed

Choose the right technology for your construction business

Request a demo

Common Challenges With Using Digital Twin in Building Construction

As promising as digital twins are, they face several challenges, particularly during the adoption phase.

Data Overload and Integration Complexity

Digital twins use data from a wide range of sources: BIM models, IoT sensors, drones, and operational systems. This creates serious integration challenges in construction environments.

Construction projects generate massive volumes of data in varied formats:

-

Structured (e.g., BIM, CSV)

-

Semi‑structured (e.g., XML, spreadsheets)

-

Unstructured (e.g,. site photos, documents)

Add high volume or velocity, and you realize why handling this is so difficult. For example, when synchronizing live sensor feeds and static BIM datasets.

Different systems often use inconsistent schemas or naming conventions. For instance, one platform might label an element as “Asset ID” while another uses a completely different identifier. This makes automated alignment prone to errors.

To solve this problem, you need to use standardized models or frameworks, such as IFC-based schemas. This will ensure semantic alignment across diverse systems.

Industry Foundation Classes (IFC) provide a structured way to represent information about buildings and infrastructure, making them suitable for integration into digital twin models.

Security and Privacy Concerns

Digital twins integrate real-time data into a dynamic virtual environment.

This introduces serious security and privacy risks:

-

Multiple entry points for an attack. Every connected device—sensor, camera, cloud service—serves as a potential entry point for attackers. A compromised IoT sensor or unsecured API could allow attackers to infiltrate the entire system.

-

Risks of corrupted data. Malicious actors can manipulate real-time data streams or simulation inputs—such as falsifying sensor readings—resulting in corrupted twin behavior and misguided decisions.

-

Exposure of proprietary data. Construction twins may contain confidential design, operational, or facility data, making them attractive targets for IP theft or industrial espionage.

This is why you need to put strong protection measures in place:

-

Role-Based Access Control (RBAC). Limit who can access, modify, or manage parts of the digital twin based on clearly defined roles and responsibilities. Regularly review and update permissions.

-

Multi-Factor Authentication (MFA). Require MFA to prevent unauthorized access, particularly for users handling sensitive data or system configurations.

-

Data encryption. Encrypt data both at rest and in transit using strong cryptographic standards. Regularly change keys and passwords. Regular privacy audits. Conduct both internal and external audits to uncover vulnerabilities. Verify encryption and ensure adherence to regulations like GDPR, ISO 27001, or sector-specific standards.

Resistance to Change and Skills Gaps

Adoption of digital twin technology requires a lot of effort from leadership and field workers. That’s why it often encounters these challenges:

-

Lack of familiarity with the concept. Many stakeholders don’t understand digital twins, including their differences from BIM and the value they offer. This leads to mistrust and unrealistic expectations.

-

Lack of skilled professionals. There’s a shortage of workers fluent in cross-domain fields such as data science, IoT, AI/ML, and construction. Without those, it’s hard to adopt digital twin technology.

-

Unrealistic expectations. Teams struggle to define a clear scope and responsibilities for digital twins. Without shared understanding and strategy, internal coordination falters, and as a result, pilot projects often fail.

Here is what you can do to solve these problems:

-

Invest in education. Develop targeted training for AEC professionals on digital twin concepts, tools, and goals. This includes video presentations and showcases to demonstrate functionality.

-

Hire or develop interdisciplinary teams. Combine professionals who have digital expertise (data science, AI/ML, systems integration) with those who possess deep knowledge of construction.

-

Clarify roles and scope early. Use workshops or cross-functional meetings to define what the digital twin will and won’t do.

-

Reduce risk. Begin with one small local project to build trust and data maturity before scaling across larger projects.

Upfront Costs and Infrastructure Setup

Full-scale digital twins demand considerable investment in sensors, cloud storage, data analytics platforms, and staff training. Implementation costs can reach up to $500,000, depending on the scale and complexity.

That’s why smaller and mid-sized construction firms often look for alternatives that provide many of the same benefits without requiring six‑figure budgets.

Get a 360° View of Your Projects With FirstBit ERP Software

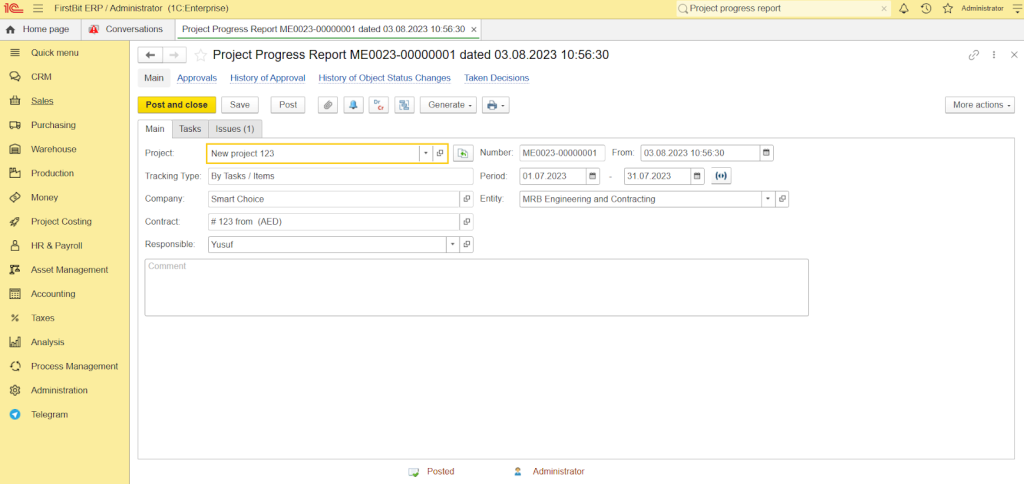

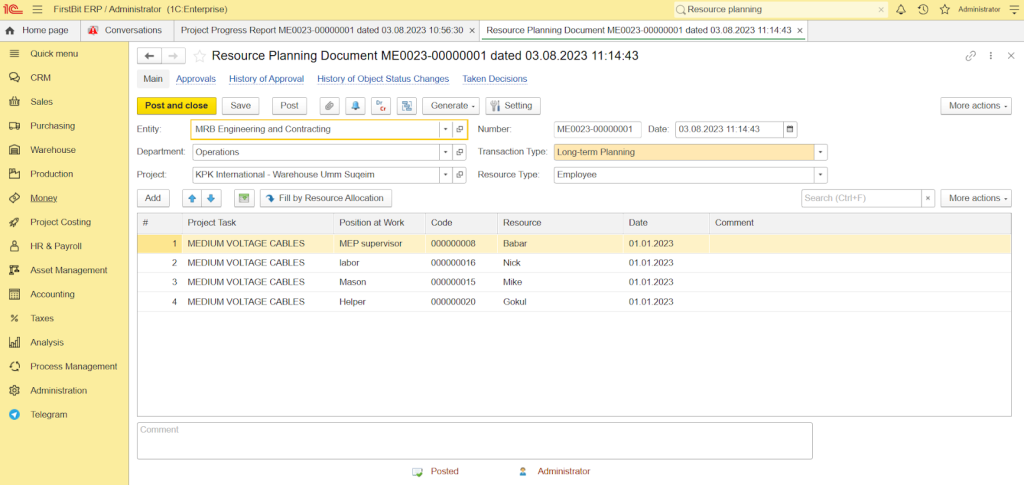

Implementation of digital twin technology delivers remarkable benefits. But it also carries significant upfront costs, complexity, and infrastructure demands. In contrast, FirstBit ERP offers a cloud‑based, ready‑made solution tailored to UAE construction firms.

This software allows you to manage project progress, control its costs, oversee the procurement process, calculate payroll, and track equipment over multiple job sites. FirstBit also includes modules that most digital twins don’t offer—namely, CRM, sales, and production.

It has all the features that construction teams need:

-

Project progress report. Get reports for every BOQ line to ensure your actual progress matches planned schedules.

-

Project performance dashboard. Gain instant, real‑time insight into cost tracking, schedule milestones, and task completion right when you need it.

-

Equipment time tracking. Monitor who’s using your tools and where they are. This will ensure efficient deployment and accountability. Track usage hours and maintenance needs to extend equipment lifespan and ensure compliance.

-

Resource planning. Strategically allocate and manage all project resources, from labor to materials.

-

Time cards. Digitally record labor and equipment hours right from the construction site to improve cost control.

-

Cash flow dashboard. Track current and projected liquidity by analyzing real-time cash inflows with outflows for more effective financial planning.

-

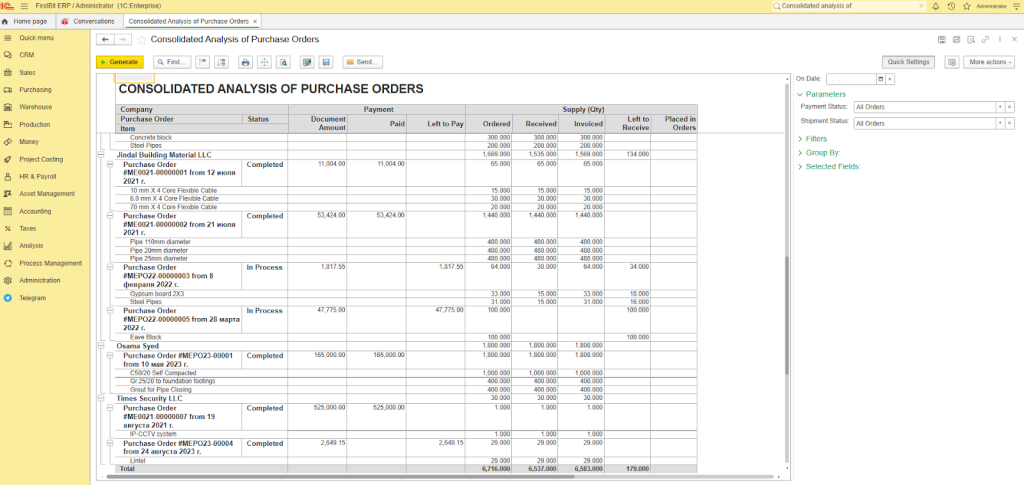

Consolidated analysis of POs. Gather and review purchase order data across projects to track costs and maintain procurement control.

-

Automated payroll calculation. Calculate salaries, overtime, leave pay, and deductions —all within a system aligned with UAE labor regulations.

ERP that saves your money

Adopt FirstBit ERP to cut costs, boost ROI, and effectively plan future cash flows

Request a demo

Final Thoughts

Digital twin technology is transforming the construction industry through real‑time insights, improved cross‑team collaboration, and powerful predictive analytics. All of them can drive better project outcomes and long‑term efficiency.

However, widespread adoption of digital twins in construction projects comes with significant challenges. Among them are security vulnerabilities, integration complexities, and high upfront costs. For organizations seeking more accessible, data-driven management alternatives today, FirstBit ERP offers a robust, industry-focused solution.

FAQ

How does digital twin technology improve construction outcomes?

Can digital twins be used for all types of construction projects?

How does a digital twin work with BIM and ERP systems?

Is a digital twin just a part of smart construction, or is it a full project solution?

Transform your business and lead the industry

Request a demo

Rafaella Dovlatyan

Contributing Author

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.