Projects often face delays and added costs when critical information arrives too late. Traditional reporting struggles to keep pace with site activity, forcing teams to react to problems rather than prevent them.

Connected devices close that gap by providing real-time visibility into operations. The use of connected devices is expanding rapidly: in 2023, there were 15.7 billion IoT devices worldwide, a number expected to reach 31.2 billion by 2030[?]. Construction is part of this surge, with the IoT market for the industry projected to nearly quadruple by 2031.

This article explores how IoT can deliver real value in construction — from automation and predictive maintenance to safety and cost control. You’ll see how to unlock its full potential and apply it effectively in your own projects.

Common Efficiency Gaps When IoT and Software Aren’t Fully Integrated

IoT data is highly useful, but without proper integration, it creates gaps. Here are the ones to watch — critical for better risk management and smoother delivery.

Common Efficiency Gaps When IoT and Software Aren’t Fully Integrated

1. Manual Data Entry Creates Delays and Errors

When IoT devices like sensors or wearables collect data on a construction site, manually entering that information into project management systems is a significant bottleneck. Picture someone jotting down equipment usage or site conditions — it can take hours to get those updates into the system.

A typo or missed number can compromise project records, leading to bad calls, rework, or arguments over what’s actually done. Without automating how IoT data flows into software, teams are stuck wading through delays and errors, missing out on the quick, accurate insights these tools are supposed to deliver.

2. Disconnected Systems Lead to Poor Coordination Between Field and Office

IoT devices collect valuable data on construction sites. If they aren’t linked to project management software, that information stays isolated.

For instance, sensors tracking material deliveries or worker tasks in the field may not integrate with the office tools. This gap leads to miscommunication, such as when office teams create schedules without incorporating the latest field updates, resulting in delays or misallocated resources. Imagine materials arriving on-site but not showing up in the system — teams end up confused about what’s available.

3. Real-Time Alerts Are Underused Without Workflow Automation

IoT sensors can instantly detect problems such as safety risks or equipment issues. Still, those warnings often get ignored without being tied to construction software. For example, a wearable device could detect a worker’s dangerously high body temperature, or a sensor could indicate that a crane is operating beyond its safe limits.

If these alerts don’t automatically reach supervisors or connect to task systems, responses are slow. Manually checking alerts wastes time and increases errors. As a result, IoT becomes less effective at improving safety and preventing breakdowns.

4. Equipment Performance Data Isn’t Used for Preventive Maintenance

IoT sensors on machinery, such as excavators and bulldozers, collect usage, wear, and potential failure data. However, construction teams cannot implement preventive maintenance strategies without software to analyze this data.

For example, a sensor might indicate early signs of engine wear. However, if this data isn’t integrated into a maintenance scheduling system, the issue may go unnoticed until a breakdown occurs. Unexpected failures lead to downtime, repair costs, and project delays. Integrated software can process IoT data to predict maintenance needs, thereby extending equipment lifespan and keeping projects on track.

5. Unused IoT Data Leads to Missed Insights

IoT devices generate vast amounts of data on construction sites, including how materials are used and how productive workers are, but without software to analyze it, that information remains untapped.

For example, sensors might show you’re burning through resources too fast. Still, if that data isn’t fed into analytics tools, you can’t spot the problem. Or take project progress — data could help fine-tune schedules, but only if it’s pulled together and shown in real time. Without software to tap into this data, teams miss chances to streamline work, cut waste, and make smarter decisions that boost the project.

Key Benefits of Integrating IoT with Construction Management Software

In practice, the impact of IoT emerges across different areas of construction management — from how teams track progress to how decisions get made.

Real-Time Visibility Across Projects and Job Sites

IoT delivers real-time visibility at construction sites. Instead of stitching together scattered reports, integrated dashboards consolidate sensor feeds with schedules, budgets, and RFIs, so managers see actual conditions as they unfold.

The advantage grows when this data is tied to BIM models and cost codes. Issues are spotted earlier, and managers at the portfolio level can compare progress across sites, reallocate assets, and balance workloads with greater accuracy.

When this visibility is applied consistently, studies show it can reduce equipment downtime by up to 30%, lower overall project costs by 10–15%, and improve safety outcomes[?].

Workflow Automation That Reduces Delays and Manual Effort

Where dashboards provide visibility, automation ensures the right action follows. IoT sensors can trigger workflows that eliminate manual steps and speed up responses.

For example, when a dust sensor detects unsafe levels, it can automatically open a safety task, alert the supervisor, and log the action for compliance. Equipment that starts overheating generates a maintenance ticket instantly, while RFID tracking of materials can prompt procurement to reorder stock before shortages hit.

These automated workflows replace reactive monitoring with real-time responses, shaving hours or even days off reaction times and freeing teams to focus on higher-value work.

Predictive Analytics for Maintenance and Risk Prevention

Predictive analytics turns raw IoT data into foresight. By studying historical records alongside real-time sensor readings, software can detect subtle patterns like recurring vibration spikes or temperature fluctuations that often precede equipment failures.

Predictive analytics allows maintenance to be scheduled at the right moment, preventing surprise breakdowns and costly project delays. Beyond equipment, the same approach can highlight recurring safety risks or inefficiencies, helping teams eliminate problems before they escalate.

Enhanced Collaboration and Communication Across Teams

IoT platforms also act as a single source of truth, keeping everyone aligned. Instead of juggling updates from multiple channels, office teams, field staff, and subcontractors access the same live dashboards.

This transparency reduces miscommunication, ensures accountability, and helps decisions flow faster. When stakeholders share one accurate view of progress, coordination improves and disputes are minimized — especially on complex, multi-party projects.

Measurable Improvements in Cost, Safety, and Productivity

The payoff of integration shows up across the board. Projects run with fewer delays, assets last longer, and safety incidents decline as risks are addressed earlier. Field crews spend less time troubleshooting and more time executing.

For investors and contractors, this translates into steadier project delivery, stronger margins, and a higher degree of confidence that resources are being used effectively.

Digital tools help capture these gains in practice. Platforms such as ERP systems provide the structure to turn sensor data into actionable insights by linking it with budgets, schedules, and compliance requirements. For example, FirstBit ERP can connect site activity with financial tracking and project workflows, ensuring that efficiency improvements at the jobsite are reflected across the entire business.

Transform your business

Embrace innovation with FirstBit ERP

Request a demo

Features to Look For in IoT-Ready Construction Software

Getting value out of IoT isn’t just about attaching sensors to equipment. It comes down to the features your software provides to make that data usable. The right platform turns thousands of raw readings into insights you can actually act on in the field.

BIM Integration

Look for software that connects IoT feeds directly to your BIM models. This lets teams track progress in real time and spot issues before they escalate.

Studies show that linking BIM and IoT can cut rework costs by as much as 15%[?]. That’s a feature that directly impacts margins.

Digital Twin Capability

A digital twin is a feature that creates a live, virtual version of your project. When paired with IoT data, it helps teams monitor conditions, test scenarios, and optimize performance.

Research suggests digital twins could save up to $950 million in design and construction costs and another $400 million in operations for non-residential projects by 2025[?].

Cloud Accessibility

Accessibility is a must-have feature. Cloud-based platforms ensure sensor data, models, and schedules are available from anywhere — whether you’re in a site office, a client meeting, or halfway across the world. Instant access keeps decisions moving and reduces downtime caused by delays in communication.

Seamless Integration With Core Tools

Finally, prioritize software that ties IoT data to your existing workflows, schedules, budgets, procurement, and cost codes. Features like automated dashboards or instant alerts mean you spend less time chasing updates and more time managing the build.

In short, do not simply ask whether a platform “supports IoT”. Instead, inquire about the features it provides to connect this data with your daily operations. This is what transforms connected devices into actual project value.

How FirstBit ERP Supports IoT Integration for Construction Firms

IoT delivers the most value when its insights flow into the systems that teams already use to manage projects, costs, and resources.

FirstBit ERP provides that central framework. Its modules are designed to capture, organize, and act on real-time information — whether it comes from field teams, automated devices, or

connected systems. For example:

-

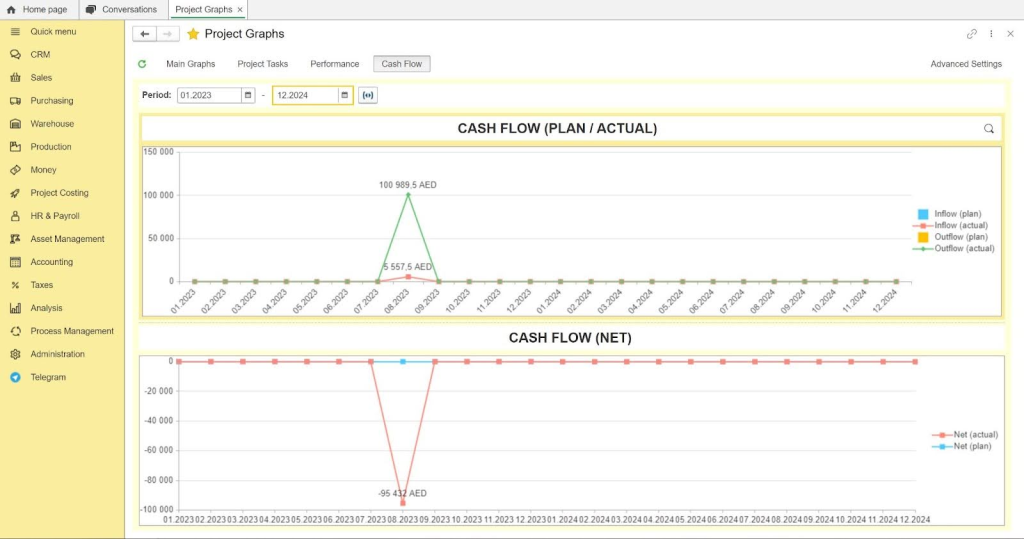

Finance and cost control. When equipment usage data or material consumption is captured by IoT devices, it can be pushed into FirstBit ERP through API connections. This can allow you to monitor allocation, P&L, and cash flow in real time without waiting for manual updates.

Project Graphs of Cash Flow in ERP

-

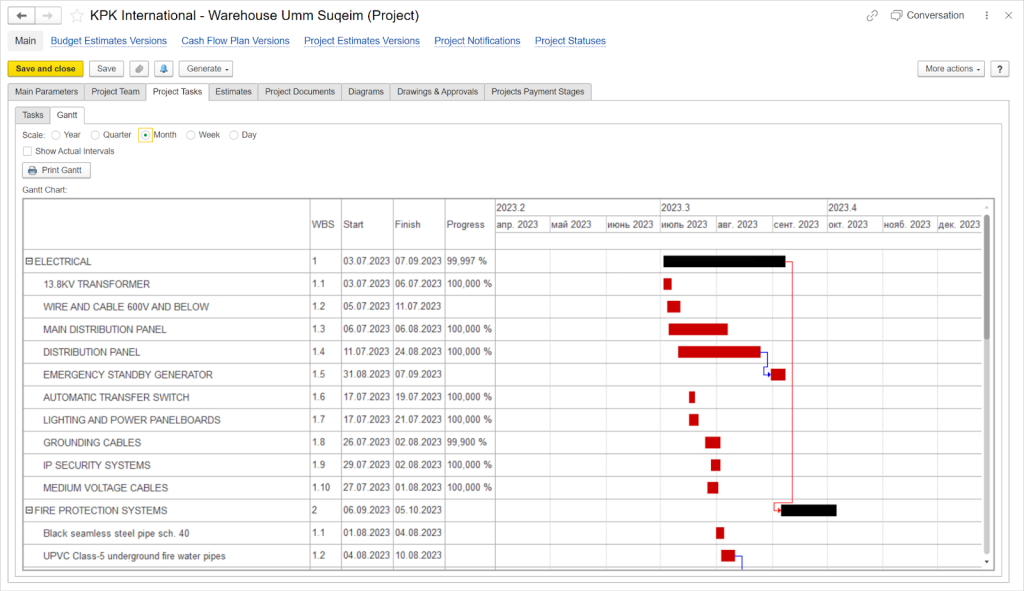

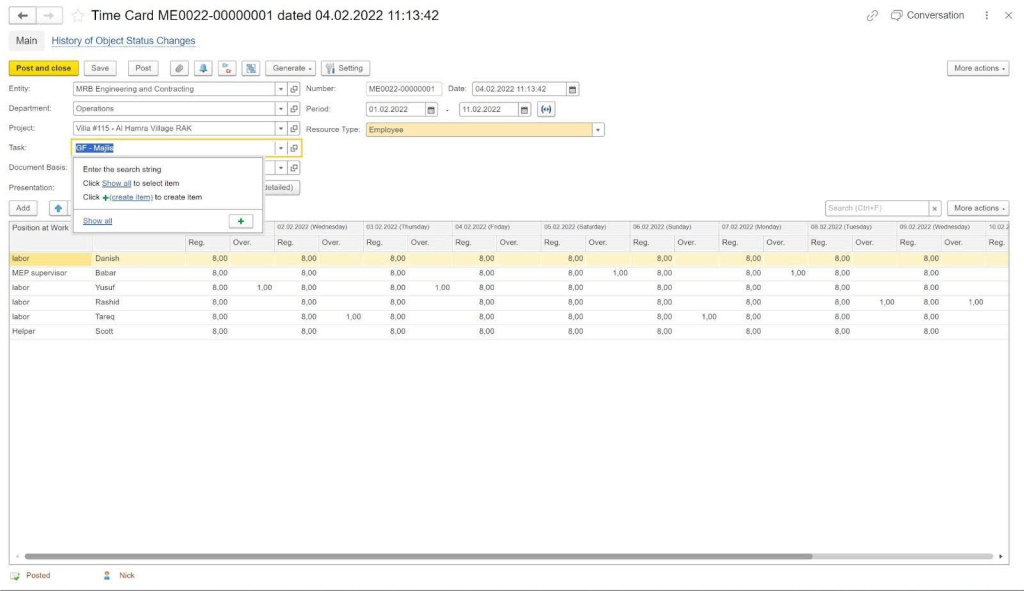

Project and resource management. To connect site activity with project schedules, you can link device signals (like equipment status or worker check-ins) to ERP task flows. That way, progress reports and Gantt charts reflect actual field conditions.

Gantt charts in FirstBit ERP

Time Card in FirstBit ERP

With this structure in place, IoT information becomes part of the bigger picture — helping firms connect costs, schedules, compliance, and performance inside a single system.

Deliver projects on time, every time

Request a demo

Final Thoughts

The real power of IoT in construction isn’t in the devices themselves; it's in what you do with the data they generate. For contractors, this means thinking beyond gadgets and focusing on workflows. Sensors, tags, and digital tools can’t replace experience, but they can give you sharper visibility, faster reactions, and more control over risks.

The firms that benefit most are those that build clear pathways for IoT data into their everyday systemsfinance, scheduling, payroll, and procurement. That’s where efficiency gains turn into real savings and safer sites.

The takeaway is simple: IoT isn’t just another technology trend. It’s a shift in how construction projects are managed from the ground up. Contractors who start aligning their processes with connected data today will be the ones setting the pace for productivity and profitability tomorrow.

F.A.Q.

1. What’s the difference between using IoT devices alone and integrating them with construction software?

IoT devices on their own collect valuable data, but without integration, that information often stays siloed. When connected to construction software, the data becomes actionable, linked to schedules, budgets, or procurement workflows, and teams can make faster decisions and reduce manual effort.

2. How difficult is it to integrate IoT devices with existing construction software?

The complexity depends on your setup. Many systems today support API-based connections, which makes linking IoT devices relatively straightforward. The main effort lies in mapping device data to the right workflows (such as cost control, inventory, or safety alerts).

3. Can IoT help with remote site management or multi-site projects?

Yes. IoT enables real-time visibility across multiple locations. Dashboards consolidate sensor inputs from different sites, so managers can monitor equipment, safety, and progress remotely without relying solely on on-site updates.

4. What kind of data security concerns should I consider when implementing IoT on construction sites?

The main considerations are securing device access, encrypting data transfers, and ensuring your software provider meets compliance standards. Without proper safeguards, IoT data could be vulnerable to breaches or misuse, so security should be built into your integration plan from the start.

5. Will I need to hire IT staff or consultants to manage IoT integration?

Not always. For many companies, integration can be handled by existing teams with support from the software provider. Larger or more complex projects may benefit from consultants during setup, but day-to-day use is often managed by project and site managers once the workflows are in place.

6. What’s the ROI timeline for IoT integration in construction projects?

Return on investment often depends on project scale and goals. Some benefits, like reduced equipment downtime or fewer delays, can appear within months. Larger savings, such as lower rework costs or improved resource allocation, typically become clear over 12–24 months as the system matures.

ERP that saves your money

Adopt FirstBit ERP to cut costs, boost ROI, and effectively plan future cash flows

Request a demo

Anna Fischer

Construction Content Writer

Anna has background in IT companies and has written numerous articles on technology topics.