Managing a growing construction business brings unique challenges, particularly when it comes to tracking materials, equipment, and resources across multiple job sites. While spreadsheets and basic software might suffice for smaller operations, they quickly become inadequate as businesses scale.

In fact, industry research shows that 98% of construction projects exceed their planned budgets, with poor materials management being a key contributor.[?]

This is where Enterprise Resource Planning (ERP) and Warehouse Management Systems (WMS) come into play, offering sophisticated solutions to streamline these complex operations. While both ERP and WMS share some features, they serve different primary purposes and can be used independently or in conjunction, depending on your specific needs.

To help you invest wisely, we'll break down the core capabilities of each system in the WMS vs ERP comparison. We’ll show you how to evaluate which solution aligns best with your business requirements.

This way, you can choose between a WMS and ERP, selecting the best option for you.

What is ERP?

ERP is a software solution that manages various business processes across multiple departments. ERP integrates a database that enables sharing of real time streaming data and collaboration.

The global market size of the resource planning ERP was valued at USD 50.57 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 10.7% from 2022 to 2030.

[?]Along with this, ERPs have long been a favorite of manufacturers and distributors because the software assists with supply chain management.

Today, 90% of businesses in the distribution and manufacturing industries have achieved full benefits realization regarding interactions with suppliers.[?]

Key features of a resource planning ERP system usually include:

-

Financial management. ERP systems offer robust financial management tools, such as general ledger, accounts payable and receivable, and financial reporting.

-

Human resources management. ERP solutions often include HR modules that handle employee records, payroll, benefits administration, and performance management.

-

Supply chain management. ERP systems provide tools for managing procurement, inventory, and logistics processes.

-

Customer relationship management (CRM). Many ERP systems include CRM functionality to manage customer interactions, sales, and marketing activities.

What is WMS?

WMS is a software application designed to optimize and manage the day-to-day operations of a warehouse. It focuses on controlling and coordinating warehouse activities, from the moment goods arrive until they are shipped out to customers.

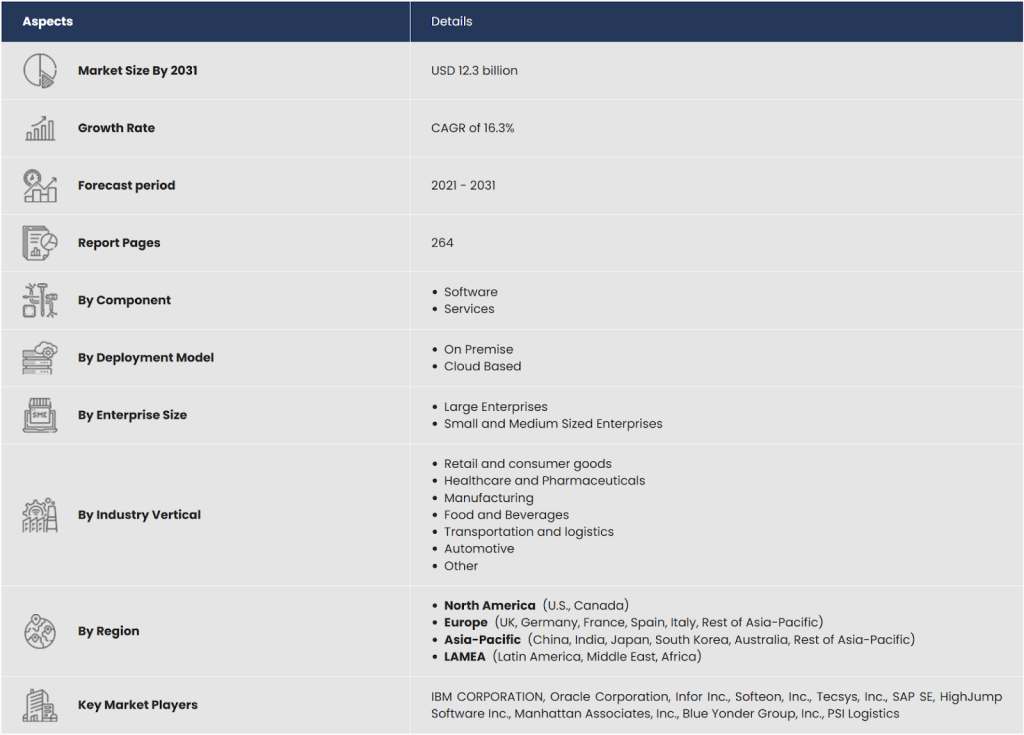

The global market of warehouse management systems is experiencing significant growth, driven by the increasing demand for efficient inventory management and the rise of e-commerce. According to market research, this industry was valued at $2.1 billion in 2020 and is projected to reach $6.1 billion by 2030, growing at a CAGR of 11.2% from 2021 to 2030.[?]

-

Inventory management. WMS helps track inventory levels, locations, and movements in real time data, ensuring accurate stock counts and reducing the risk of stockouts or overstocking.

-

Order processing. WMS enables efficient order processing, from picking and packing to shipping, helping warehouses fulfill orders quickly and accurately.

-

Barcode scanning and RFID tracking. WMS systems often integrate with barcode scanners and RFID technology to enable real time data tracking of goods and assets within the warehouse.

-

Labor management. WMS can help optimize workforce allocation and productivity by tracking employee performance and assigning tasks based on workload and skill levels.

As e-commerce continues to grow and supply chains become more complex, the role of Warehouse Management Systems (WMS) in ensuring efficient and accurate warehouse operations will only become more critical. In fact, a survey by Zebra Technologies found that 74% of respondents reported improved inventory accuracy after implementing a WMS.

[?]

Managing your business becomes simpler when your WMS works as part of your ERP system. For example, FirstBit ERP offers a complete platform that connects your construction projects and warehouse operations, making it easy to manage multiple storage locations from one place.

Keep all supplies organized

Manage warehouses via FirstBit ERP

Request a demo

ERP vs. WMS: Key Differences

While ERP and WMS both aim to optimize operations, they cater to different aspects of a business and are often used in tandem. Understanding their unique roles and how they intersect can help organizations prioritize investments based on their operational needs.

1. Scope of Functionality

-

Resource planning ERP acts as a central hub for managing cross-departmental workflows, including finance, HR, sales, procurement, and supply chain.

-

WMS specializes in warehouse-specific operations, such as inventory tracking, order fulfillment, and labor management.

2. Depth vs. Breadth

-

ERP provides broad but relatively shallow coverage across many business functions, offering basic to intermediate capabilities in each area without diving too deep into specifics.

-

WMS offers deep, detailed control over warehouse operations, with sophisticated features like slotting optimization, wave planning, yard management, and advanced picking algorithms that wouldn't be found in an ERP system.

3. Implementation Complexity

-

ERP implementations usually take longer and are more complicated because they affect the whole organization. It takes between 18 and 24 months to implement all the key parts of an ERP system in a traditional way.

[?]

-

WMS deployments are faster and more focused, often requiring only a few weeks, depending on the complexity, as they target a single operational area.

4. Scalability

-

ERP scales with the entire organization, supporting growth across departments, geographies, and regulatory environments. It can flexibly expand both horizontally (adding new business units or locations) and vertically (deepening functionality within departments), making it ideal for organizations with global ambitions.

-

WMS scales within warehouse operations, adapting to increased inventory volumes, SKU counts, or order fulfillment demands.

5. Integration Capabilities

-

ERP can integrate with external systems, including WMS, CRM, or e-commerce platforms, to create a unified real time data ecosystem.

-

WMS often functions as a standalone system but may connect to ERP for inventory or order data sharing.

6. Cost Considerations

-

ERP requires a larger upfront investment due to its complexity and scope. It can cost anywhere from $20,000 to $500,000+, factoring in licensing, implementation, training, and ongoing support. Costs rise quickly with modules, customizations, and integrations. Add-ons like mobile access or industry-specific tools often come at a premium.

-

WMS is generally more budget-friendly for businesses needing to optimize warehouse operations without overhauling their entire IT infrastructure. They start at $5,000 or as low as $300/month for cloud options. However, features like barcode scanning, multi-site support, or API access may incur extra fees. It's budget-friendly upfront, but less scalable long term.

For businesses with large-scale operations, such as construction projects, integrating WMS into an ERP system can be particularly advantageous. While ERP manages project timelines, budgets, and cross-departmental coordination, a specialized WMS ensures materials, equipment, and inventory are tracked and allocated efficiently on-site.

Benefits of Integrating WMS into ERP for Construction Projects

Construction businesses can face unique challenges in managing resources, inventory, and project timelines. An integrated ERP WMS solution addresses these challenges while streamlining operations across all project stages.

1. Enhanced Inventory Visibility and Control

When you bring ERP WMS capabilities together, you get a clear picture of what's happening with your inventory across all construction sites and warehouses in real time.

The system automatically collects data using practical tools like barcode scanners and RFID tags, then organizes everything in one easy-to-access platform. This means your managers can see exactly what's available, where it's located, and how it's moving – helping them make better decisions with confidence, knowing they're

managing materials with the latest information. It is one of the main advantages of integration.

2. Improved Resource Allocation and Utilization

Connecting your WMS and ERP systems helps you make the most of every resource on your construction projects.

The combined system looks at all your data to show you exactly what materials you need and which equipment is available. You'll see everything laid out clearly in dashboards and reports that make sense at a glance. This means your managers can quickly spot trends, adjust their plans, and make smarter decisions.

Plus, the system learns from your past projects to suggest the best ways to distribute resources, taking into account both your current needs and what's worked well before. In this way, ERP WMS integration becomes a driver for improved allocation.

3. Streamlined Procurement and Supply Chain Management

When you bring your WMS and ERP systems together, managing purchases and supplies becomes much smoother. While your ERP system takes care of purchase orders and approvals, your WMS keeps track of deliveries and makes sure materials reach your construction sites on time.

You won't need to enter the same information multiple times – the system handles data sharing automatically between purchasing, inventory, and project teams. This means fewer mistakes, less paperwork, and better relationships with your suppliers. You'll avoid costly delays, keep your spending in check, and maintain a reliable supply chain that keeps your projects moving forward.

4. Increased Collaboration and Communication

Having your WMS and ERP systems work together creates a unified platform where your entire team can collaborate effectively. Everyone can easily access the documents, data, and updates they need, while the system ensures each team member sees only the information relevant to their role.

Need to know what's happening on your project right now? The system keeps everyone informed with instant updates about progress, changes, or potential issues. Your team can share calendars, assign tasks, and coordinate their work seamlessly – making it easier for everyone to stay aligned and work together efficiently with ERP WMS connectivity.

5. Enhanced Reporting and Analytics

When you combine your WMS and ERP systems, you'll get valuable insights from all your project data in one place. The system pulls information from across your operations and organizes it so you can easily analyze what's happening in your business.

You'll get both ready-to-use and custom reports that show you exactly how your projects are performing, what's happening with your inventory, and how well you're using your resources.

The system's advanced analytics help you spot trends early, predict what you'll need in the future, and find smarter ways to work. You can make confident decisions based on solid data, rather than guesswork, and continuously improve your operations. You can make confident decisions based on solid data, rather than guesswork, and continuously improve your operations with the support of ERP WMS integration.

6. Improved Compliance and Risk Management

When you integrate your WMS and ERP systems, staying compliant and managing risks becomes much easier. The system automatically collects and stores all your important records, so you'll always have accurate data ready for compliance reports. You can set up the system to follow your specific compliance requirements, including safety protocols and quality inspections.

The system watches for compliance concerns and alerts you before they become problems, letting you address them quickly. Plus, you'll have a complete record of all activities and transactions, making audits straightforward and helping you avoid penalties. This means you can focus more on running your projects and less on paperwork and compliance worries.

Always have the right materials on site. Track inventory in FirstBit ERP.

Request a demo

Case Study: The Importance of WMS in ERP for Moon Link Building Contracting LLC

Moon Link Building Contracting LLC, a construction company based in the United Arab Emirates, faced challenges in managing its warehouse operations efficiently. The company needed a comprehensive ERP system to streamline processes, strengthen its supply chain, and improve construction efficiency.

Before implementing FirstBit ERP, Moon Link Building Contracting LLC encountered several difficulties in their warehouse management:

- Difficulty in inventory management across multiple warehouses

- Inefficient manual processes for material requisitions and transfers

- Lack of real time visibility into stock levels and material availability

- Challenges in managing and tracking assets across construction sites

The WMS module within FirstBit ERP provided essential features to enhance warehouse operations. The system improves inventory management due to the real time inventory tracking. It gives accurate visibility of inventory levels, locations, and movements. Through barcode scanning technology, the process of receiving, storing, and issuing materials became streamlined, reducing manual errors and increasing efficiency.

The WMS also improved material allocation and tracking, ensuring proper delivery of materials to specific construction projects at the right time. Additionally, the system automated various warehouse processes like picking, packing, and shipping, which reduced manual intervention and improved overall productivity.

The case study of Moon Link Building Contracting LLC highlights the importance of WMS in ERP for construction companies. This case study demonstrates how a well-integrated WMS within an ERP system can significantly contribute to the overall efficiency and success of construction projects, , particularly through better supply chain coordination.

ERP vs. WMS Comparison

Before making a decision between ERP and WMS systems, it's crucial to understand their distinct capabilities, limitations, and how they address different business needs.

Pros and Cons of ERP

ERP systems integrate finance, HR, manufacturing, and supply chain operations into a unified system, enabling real time data sharing and informed decision-making across the organization.

The nature of ERP systems does present challenges. Implementation requires substantial time and financial investment. Organizations must commit to extensive staff training and adapt to new processes. While ERPs include warehouse management capabilities, these features may not match the depth of specialized WMS solutions.

Pros and Cons of WMS

WMS focuses exclusively on optimizing warehouse operations. They provide detailed control over inventory movement, storage optimization, and order fulfillment processes. WMS platforms offer space utilization, and maintaining accurate inventory levels. Like ERP, WMS provides the information in real time.

Implementation of WMS is typically faster and less expensive than ERP systems. However, WMS functionality is limited to warehouse operations. It doesn't address broader business needs such as financial management, customer relationships, or manufacturing processes. Organizations often need additional software solutions to manage these aspects of their supply chain.

Gain full control of your business

Get a 360° project view with FirstBit ERP

Request a demo

How to Choose Between ERP and WMS for Your Business

The choice between ERP and WMS depends on your organization's operational focus and complexity. Businesses primarily concerned with warehouse operations may find a dedicated WMS sufficient. Organizations managing complex operations across multiple departments typically require the comprehensive capabilities of an ERP system.

Key decision factors include:

-

Identify specific issues your organization faces daily. For example, if you struggle with inventory accuracy or order fulfillment delays, these problems will guide your software choice - start with a WMS. It will solve these immediate warehouse challenges faster and more cost-effectively than a full ERP implementation.

-

Consider the number of employees, locations, and daily transactions you manage. For organizations with 20 or fewer employees in a single location, WMS is typically sufficient. However, if you manage multiple locations with complex inter-departmental workflows, ERP becomes necessary to maintain operational cohesion.

-

Calculate not just the initial software cost, but also implementation, training, and ongoing maintenance expenses. Include potential hardware upgrades and additional IT staff requirements in your budget planning.

-

Determine how quickly you need the system operational. Implementations of ERP systems typically take 6-12 months, while WMS can be deployed in a few months, depending on complexity.

-

When multiple existing systems need integration (accounting, CRM, e-commerce), ERP becomes the more practical choice as it provides built-in integration capabilities and eliminates data silos.

-

For businesses planning significant expansion in the next 3-5 years, investing in ERP systems now can prevent costly system changes later. However, if growth plans focus mainly on warehouse operations, a scalable WMS might be sufficient.

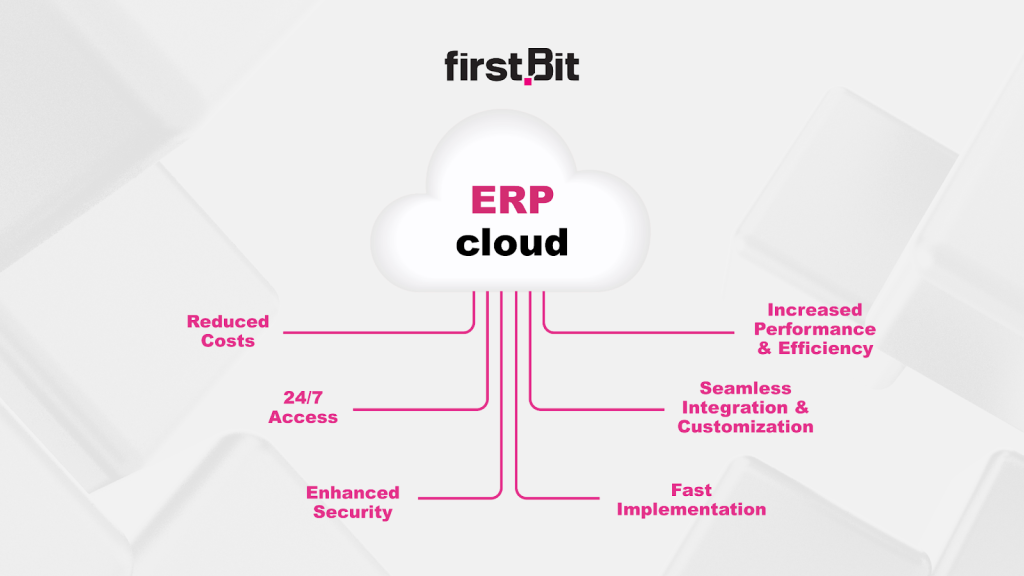

Why FirstBit ERP Is the Ideal Choice for Your Business

When managing both business operations and warehouse activities becomes challenging, FirstBit ERP offers a practical solution. The system brings warehouse management and business operations together in one platform, making it easier to control multiple warehouses. Organizations can track inventory automatically, manage batches, and monitor serial numbers while maintaining real-time visibility across all locations and warehouses..

The system's warehouse management functionality includes:

-

Automated purchase planning based on stock levels

-

Multi-location inventory tracking and transfer management powered by ERP system

-

Stock valuation through FIFO, LIFO, and weighted average methods

-

Batch and serial number tracking for precise inventory control

-

Minimum and maximum stock level monitoring

-

Automated reorder point calculations in ERP system

-

Multiple units of measure support

-

Barcode scanning integration

-

Real-time inventory reporting and analytics

The platform streamlines supply chain operations by automating stock transfers, monitoring goods in transit, and maintaining accurate cost calculations. Built-in analytics tools provide insights into inventory turnover and stock aging, enabling data-driven inventory management decisions.

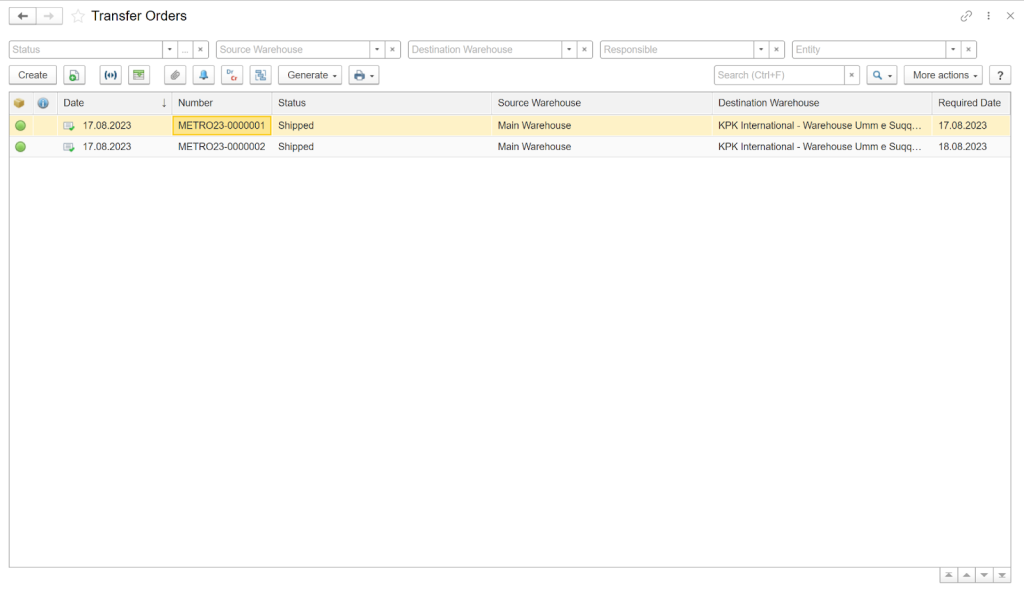

Transfer Orders in FirstBit ERP

FirstBit's warehouse management capabilities integrate seamlessly with other business processes, ensuring consistent data flow between procurement, sales, and financial operations.

This integration eliminates manual data entry and reduces the risk of errors while providing comprehensive business visibility across the supply chain. For growing companies, such ERPs deliver the scalability needed to adapt and thrive in competitive markets.

Explore efficient ERP solutions for your construction business

Request a demo

FAQ

1. What is the difference between ERP and WMS?

A WMS (Warehouse Management System) is a specialized tool focused on optimizing and managing warehouse-specific operations like real-time inventory tracking, order picking, and bin organization, while an ERP (Enterprise Resource Planning) system is a broader, organization-wide platform integrating functions such as finance, HR, procurement, and supply chain management.

2. What is the difference between ERP and inventory management system?

An ERP (Enterprise Resource Planning) system is a comprehensive, organization-wide platform that integrates core business functions like finance, HR, supply chain, and inventory management into a single real-time system, while an Inventory Management System (IMS) is a more narrowly focused tool dedicated solely to tracking, managing, and controlling stock levels, orders, and inventory flows.

3. What is the difference between ERP and data warehouse?

A data warehouse is a centralized repository designed for reporting and analyzing historical and aggregated data from various systems to support strategic decision-making, whereas an ERP (Enterprise Resource Planning) system manages and integrates real-time, operational business processes across departments like finance, procurement, and HR.

4. What is the difference between ERP and MDM?

A Master Data Management (MDM) system focuses on standardizing, governing, and maintaining a single, consistent "source of truth" for critical enterprise data (like products, vendors, or customers), whereas an ERP (Enterprise Resource Planning) system is designed to execute and streamline core business processes across finance, HR, supply chain, and more.

5. Do I need both ERP and WMS for my business?

Most businesses don't need both systems separately. Modern ERP solutions, like FirstBit, include robust WMS functionality, providing a single integrated platform that manages both warehouse operations and broader business processes efficiently.

6. What are the key benefits of using an ERP over a WMS for the construction industry?

For construction companies, ERP systems offer comprehensive project management, financial control, and warehouse management in one platform. This integration ensures better cost tracking, streamlined procurement, and efficient material management across multiple construction sites while maintaining full visibility of business operations.

7. Can an ERP and WMS work together?

Yes, ERP and WMS systems can be integrated, but this creates unnecessary complexity and additional costs. Choosing an ERP system with built-in WMS functionality, like FirstBit, provides a more efficient and cost-effective solution while ensuring seamless data flow between warehouse operations and other business processes.

Anna Fischer

Construction Content Writer

Anna has background in IT companies and has written numerous articles on technology topics.