Equipment downtime affects productivity, budgets, and client trust. A single breakdown can stall a project, delay schedules, and lead to costly emergency repairs. At the same time, preventive maintenance can feel like an unnecessary expense.

It's essential to understand the difference between breakdown and preventive maintenance since not every machine requires frequent servicing, and not every failure can be avoided.

In this article, we discuss each approach in detail and provide steps for better application in construction projects. The piece also explores real-life examples of both approaches in construction and the consequences contractors faced.

Preventive Maintenance

Construction projects depend on machines that can’t afford unexpected breakdowns. A preventive maintenance system sets the foundation for reliability and safety.

Preventive Maintenance Meaning

The meaning of preventive maintenance lies in its proactive nature: inspections, servicing, and replacements are carried out before problems arise. The principle is straightforward — plan repairs in advance rather than stop work for emergencies.

In fact, predictive maintenance can reduce equipment downtime by 30-40%, and increase equipment life by 20-40%[?].

Types of Preventive Maintenance in Construction

A preventive maintenance system can be structured in different approaches, depending on asset use and risk profile. The most common methods are:

Time-based maintenance is scheduled at fixed intervals such as weekly, monthly, or yearly, regardless of the machine’s current condition.

Usage-based maintenance is triggered after a defined number of operating cycles, hours, or mileage, making it ideal for heavy-duty equipment.

Condition-based maintenance is initiated by monitoring tools or sensors that detect wear or performance anomalies, prompting timely intervention.

Typical Tasks in Preventive Maintenance

On a construction site, preventive maintenance shows up in simple but critical routines that keep equipment working day after day. Skipping these steps may save minutes in the short term, but can lead to costly repairs when machines break down.

Typical tasks include:

Visual checks for leaks, cracks, or wear that could escalate if ignored

Applying grease or oil to keep moving parts from grinding down

Swapping belts, filters, or seals before they fail under heavy loads

Every task in a preventive maintenance system extends the lifespan of equipment and avoids the steep expense of emergency fixes, turning routine service into real savings.

Breakdown Maintenance: Meaning

Unlike preventive maintenance, which prevents issues before they occur, breakdown maintenance is reactive and performed only after an asset fails. Although it may seem risky, this run-to-failure approach can be the most practical and cost-effective option when failure is acceptable.

When It’s Used in Construction

In construction, breakdown maintenance applies only to low-cost or non-critical equipment where failure does not affect operations, safety, or compliance. Rather than scheduling regular service, the asset is repaired or replaced once it stops working.

Common examples include:

Light fixtures in temporary or low-traffic site areas

Small printers or scanners in site offices

Non-structural door mechanisms

Low-cost pumps or valves with a short expected lifespan

This approach is practical when routine maintenance costs more than replacement. However, using it for critical systems such as load-bearing machinery, safety gear, or ventilation can turn small savings into major downtime or compliance risks.

Hidden Risks in Equipment Failure

Even small components can trigger major accidents if maintenance is overlooked.

At one construction site, a mini-excavator developed a leak in a hydraulic fitting on the boom. When the fitting gave way, the boom lost pressure and dropped suddenly, striking a nearby worker[?].

Cases like this highlight why relying on breakdown maintenance for critical equipment is risky.

Keep equipment in the best condition

Monitor equipment warranties and certifications

Request a demo

Difference Between Breakdown and Preventive Maintenance

Comparing types of maintenance at-a-glance

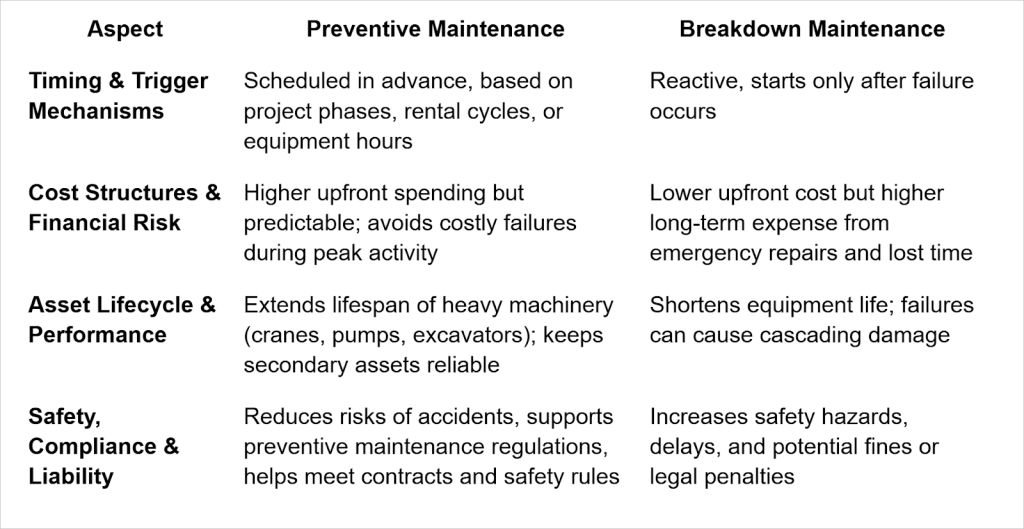

Timing & Trigger Mechanisms

Preventive maintenance involves scheduling tower crane inspections every 500 operating hours to avoid sudden failures mid-lift.

In a breakdown model, the crane would only be serviced after a fault occurs, which could happen during a critical lift and halt operations for days.

Cost Structures & Financial Risk

Routine servicing of concrete pumps during off-hours spreads costs evenly and prevents emergency callouts. The difference between breakdown maintenance and preventive maintenance here is financial stability.

If a pump line bursts mid-pour, the contractor not only pays for urgent repairs but also for wasted materials and possible demolition of defective sections.

Asset Lifecycle & Performance

Excavators that receive regular track and hydraulic maintenance last years longer and remain productive across multiple projects.

Under breakdown maintenance, running components to failure shortens equipment life and leads to expensive overhauls. The difference between these two approaches directly affects how long a machine remains profitable.

Safety, Compliance & Liability

Preventive care ensures that site generators and fire suppression systems meet inspection requirements.

A breakdown approach, on the other hand, risks power loss during peak operations or non-compliance with safety standards, exposing contractors to fines or legal action. Understanding the difference between breakdown maintenance and preventive maintenance can be the deciding factor between a safe, compliant site and a costly incident.

8 Steps of Preventive Maintenance

Creating a preventive maintenance system means breaking it down into practical steps. These 8 steps of preventive maintenance build on the previous one to make the program clear, measurable, and workable on-site.

Step 1: Inventory and Categorize Assets

The first step of preventive maintenance is to

list every piece of equipment you plan to maintain. This is your foundation. Once you know what you’re dealing with, group the assets into categories based on type or function. For example: cranes, pumps, HVAC, generators. Clear categories keep the scope realistic and stop critical assets from being overlooked.

What to do

Walk through the site, record all assets in a register, and tag them by category so you know exactly what’s on your list. Capture details in a central log to make future planning easier.

Step 2: Prioritize by Criticality, Cost, Risk

Not every asset deserves equal attention. Preventive maintenance management starts by ranking them. Aspects you should look at:

Criticality. Look what happens if this asset fails during operations

Cost. Pay attention to both repair cost and downtime cost

Risk. Monitor safety, compliance, or contractual impact

This way, you focus your resources where they matter most. A tower crane or fire suppression system gets top priority; a small site printer does not.

What to do

Run an asset criticality assessment, assign scores, and create a tiered priority list so the most important equipment is always maintained first.

Step 3: Define Maintenance Triggers

Once priorities are clear, set the triggers that decide when maintenance happens. These can be:

Time-based: inspections every month or after a set number of days.

Usage-based: checks after a number of cycles, hours, or miles.

Condition-based: actions triggered by sensor readings or performance thresholds.

What to do

Defining triggers keeps the preventive maintenance system consistent instead of waiting for random failures.

Step 4: Develop Task Lists, SOPs, Checklists

With triggers in place, create structured task lists and standard operating procedures. This means writing down what must be done for each inspection or service. Typical checklists include:

Visual inspections for leaks, cracks, or wear

Lubrication points and intervals

Replacement parts such as filters, belts, or seals

A clear list ensures every technician knows what to do, how to do it, and when. This consistency supports compliance with preventive maintenance regulations and helps cut costs by catching issues before they escalate.

What to do

For each critical asset, write down the exact interval or usage measure when checks must be performed and link it to your maintenance schedule.

Step 5: Schedule Recurring Preventive Tasks

Once the right triggers are set, the next step is to build them into a recurring schedule. These intervals must reflect equipment type, usage, manufacturer recommendations, and actual performance data. In construction, scheduling can’t be random — equipment downtime must align with project phases and site activity. Variables to consider include:

Manufacturer’s service guidelines

Performance history of the asset

Criticality to ongoing operations

Cost of repair vs. routine service

Projected workload

Root cause analysis (RCA) after failures also helps refine future schedules by eliminating repetitive mistakes.

What to do

Document the frequency for each task, log it into your central maintenance calendar, and link it with work order creation. If you use project management software, automate reminders so recurring preventive maintenance tasks appear in technicians’ task lists on time.

Step 6: Allocate Resources, Parts, and Labor

A preventive maintenance plan is only effective if resources are ready when needed. That means assigning the right people, stocking parts, and making sure tools are on hand before a task is due. In construction, this often means preparing spares for pumps, belts, or filters before a heavy-use phase begins.

What to do

Create a resource plan that links each scheduled task to required parts and labor hours. Review inventory so spares are available, and assign tasks to technicians with the right skills. Digital resource allocation tools can help you balance workload across teams.

Step 7: Execute Inspections, Servicing, Calibration, Testing

Once resources are in place, inspections and servicing must be carried out exactly as planned. These aren’t just visual checks but also include lubrication, calibration of instruments, testing safety systems, and verifying performance thresholds. On a construction site, this can mean checking crane cables for wear, calibrating concrete batching equipment, or testing backup generators.

What to do

Perform each task using a checklist or Standard Operating Procedure (SOP) so nothing is overlooked. Record results immediately after completion, whether on paper or in a mobile app. Supervisors should spot-check key assets to ensure consistency across the team.

Step 8: Monitor Performance, Record Results, and Refine Frequencies

Preventive maintenance is not static. Every inspection, repair, or calibration generates data that must feed back into the system. Monitoring results allow you to confirm whether downtime is being reduced and assets are performing as expected. Over time, these records reveal whether intervals are too frequent, too long, or just right.

What to do

Track results against your KPIs, review variances with the team, and adjust schedules where necessary. Use digital dashboards to visualize trends, then refine preventive maintenance task frequencies so they reflect real operating conditions rather than assumptions.

Keep your equipment running smoothly

Request a demo

Steps of Breakdown Maintenance

When equipment fails, follow this sequence to move from detection to safe repair and capture data for future prevention.

Step 1: Detect or Receive Report of Failure / Downtime

The process begins when equipment fails or shows signs of malfunction. Failures are often reported by operators, safety staff, or monitoring systems on site. Quick detection is essential to minimize downtime.

What to do

Record the time, location, and nature of the issue as soon as it is noticed.

Step 2: Initiate Work Order and Notify Maintenance Team

Once the failure is identified, a work order should be created and assigned. The right team members must be informed immediately to reduce delays.

What to do

Log the problem in your maintenance system and notify the responsible technician or crew leader.

Step 3: Diagnose Fault (Inspection, Root Cause Analysis)

Before any repair begins, the asset must be inspected to confirm the nature of the failure. This step also includes identifying the root cause so future issues can be prevented.

What to do

Carry out a detailed inspection, check recent performance records, and document what caused the downtime.

Step 4: Determine Repair vs Full Replacement

Not every failure can be fixed with a small repair. Sometimes, parts or the whole unit need replacing. The decision depends on cost, time, and availability of spares.

What to do

Evaluate whether the repair will restore reliability or if replacement is more efficient in the long run.

Step 5: Secure Necessary Parts, Tools, and Safety Measures

Once the path is chosen, all required parts, equipment, and safety measures must be prepared before work begins. This ensures the repair team can work without interruptions.

What to do

Check spare parts inventory, gather the needed tools, and put safety measures in place before touching the asset.

Step 6: Perform Repair or Replacement

The actual work is carried out based on the diagnosis and chosen action plan. This may involve mechanical repair, part swaps, or full equipment replacement.

What to do

Execute the task according to standard operating procedures while documenting each action.

Step 7: Test and Validate Restored Operation

Repairs must always be verified to ensure the asset is safe and fully functional before returning it to service.

What to do

Run an operational test under normal load and confirm the equipment works as expected.

Step 8: Document the Repair

All information about the failure and the repair must be recorded. This creates a reference for future breakdowns and helps track maintenance costs.

What to do

Update logs with fault details, parts replaced, hours worked, and downtime duration.

Step 9: Review Failure Trends; Feed Data into Preventive Planning

Every breakdown provides insights into how maintenance can be improved. Reviewing trends helps shift from purely reactive fixes to preventive planning.

What to do

Analyze recurring faults and use the data to adjust preventive maintenance schedules, reducing the chance of similar failures.

Best Practices for Breakdown and Preventive Maintenance Management

Both preventive and breakdown maintenance play a role in construction, but they require different approaches. Preventive practices focus on planning, monitoring, and extending equipment life, while breakdown practices deal with fast, organized responses when failure occurs.

Best Practices for Preventive Maintenance Management

Preventive maintenance is most effective when it combines technology, priorities, training, and continuous improvement. Here are the core practices construction managers should follow:

1. Use a CMMS or ERP system

A CMMS or ERP platform centralizes schedules, reminders, and inspection records. Automated alerts ensure recurring tasks aren’t missed, while history logs help managers see patterns and improve decision-making.

2. Prioritize by asset criticality

Not all assets need the same level of attention. Focus first on cranes, concrete pumps, and generators where downtime is most costly. Lower-priority tools can be handled on simpler schedules, freeing resources for critical equipment.

3. Invest in staff training

Well-trained technicians spot issues earlier and complete tasks more efficiently. Regular workshops on inspection, lubrication, and calibration reduce errors and keep the preventive maintenance system consistent across teams.

4. Use performance data to refine intervals

Install monitoring devices or review sensor data to adjust maintenance frequency. Instead of relying only on manufacturer intervals, managers can track wear patterns and schedule service just before failure risks increase.

5. Continuously review and adjust

Compare downtime, cost, and failure trends against your preventive maintenance goals. If inspections take too long or certain assets fail more often than expected, refine schedules and update checklists to close the gaps.

Best Practices for Breakdown Maintenance Management

Breakdown maintenance has its place, but only when it’s carefully managed and applied to the right assets. These practices help construction teams use it effectively:

1. Keep a spare parts inventory

Having critical spares like belts, seals, or small pumps on hand reduces downtime when failures occur. Without stock, a simple breakdown can hold up an entire site until parts are sourced.

2. Define roles and response protocols

When equipment fails, every minute counts. A clear chain of responsibility — who inspects, who authorizes repairs, who orders parts — ensures rapid response instead of confusion on site.

3. Document every breakdown

Log details such as the failure cause, repair method, duration of downtime, and costs. This record provides insight into recurring weak points and supports both budgeting and future preventive maintenance planning.

4. Use failure data to adjust strategy

If certain assets fail repeatedly, they may no longer be suitable for a run-to-failure approach. Analyzing patterns helps managers decide when to shift those items into a preventive maintenance schedule.

5. Apply breakdown maintenance only to low-impact assets

This model should be reserved for items where failure does not halt operations or compromise safety, such as light fixtures, non-critical pumps, or small office equipment. Using it on high-value or safety-critical machinery creates unacceptable risks.

Extend equipment lifecycle

Schedule maintenance and avoid downtime with FirstBit

Request a demo

Strategic Application on Construction Projects

Putting maintenance into practice on site means matching the method to asset risk, mixing strategies where it makes sense, using data for timing, and working within real constraints.

Strategic application on construction projects

Assess Asset Criticality

Start by determining which assets cannot fail during operations. Assess each one using three simple criteria: impact on timeline, cost, and safety.

Based on these criteria, you can ask yourself the following questions:

Impact on timeline: Will a failure stop a critical path activity?

Impact on cost: Will downtime idle crews or waste materials?

Impact on safety: Could a failure create a safety incident or breach permits?

Once scored, tier your assets accordingly:

Critical: tower cranes, hoists, concrete pumps, primary generators, fire suppression systems.

Non-critical: temporary site lighting, small office printers, non-load-bearing door gear.

This ranking clarifies what needs preventive attention first and what can operate until failure without major risk.

Hybrid Approach & Mixed Strategies

Most construction projects benefit from a blend of preventive and breakdown maintenance. Apply preventive maintenance to equipment that directly affects schedule and safety, and use breakdown maintenance where failure has minimal impact.

Preventive strategy for assets, such as tower cranes, material hoists, and concrete pumps.

Run-to-fail strategy for assets, such as corridor lights, small fans, and temporary signage power.

Set this balance at the start of the project, review it at every phase change, and adjust as the risk profile evolves.

Use of Technology & Data

Preventive maintenance software for manufacturing makes it easier to manage and scale maintenance programs. A CMMS or ERP system, such as

FirstBit ERP, centralizes schedules, work orders, and asset history, while connected sensors enhance insight and timing.

The special constructor software will allow you to monitor, get alerts, and watch over predictive insights.

Telematics and IoT sensors track hours, vibration, temperature, and hydraulic pressure, while automatically notifying when thresholds or service hours are reached. Trend data indicating when components such as bearings, lines, or seals are likely to fail, allowing service to be planned during off-hours.

Using uniform asset IDs and checklists keeps maintenance organized and consistent across all sites. It means that when every piece of equipment has the same kind of identification code and follows the same inspection checklist, maintenance teams can work in a unified way across all sites.

In other words, standardized asset IDs and checklists help keep maintenance records organized, avoid confusion between similar machines, and ensure that the same quality and procedures are applied everywhere.

Practical Constraints & Challenges

Every site faces limits that shape maintenance planning. Labor and scheduling can be difficult with limited technicians, night pours, and narrow access windows. Budget trade-offs often arise between holding spare parts, arranging rentals, or paying for emergency call-outs. Harsh conditions such as heat, dust, humidity, and shock loads accelerate wear and make generic intervals unreliable.

Document these constraints early so that service windows, parts stocking, and technician schedules align with site realities.

How FirstBit Transforms Breakdown and Preventive Maintenance Management in Construction

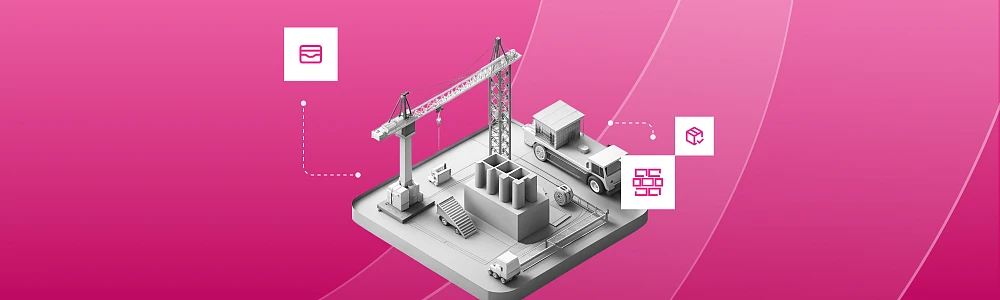

FirstBit ERP serves as a centralized system for preventive maintenance software for manufacturing and construction. It’s managing all construction equipment data in one place. This digital support will help you monitor asset usage, track maintenance schedules, and prevent unplanned downtime through clear visibility and timely alerts.

From a single dashboard, project managers can see who is using each machine, how long it has been in operation, and when the next inspection is due. Automated reminders ensure that servicing,

document renewals, and safety checks happen on time, reducing the risk of sudden failures.

Equipment management Gantt chart in FirstBit ERP

The system also makes it possible to track maintenance costs, depreciation, and equipment performance over time. This data supports better decisions about repairs, replacements, and fleet optimization, keeping machines reliable and projects on schedule.

Fixed assets document expiration dates in FirstBit ERP

By turning equipment management into a structured, data-driven process,

FirstBit ERP allows teams to move from reactive maintenance to proactive control of their assets. This shift reflects the same principle seen across successful maintenance strategies: preventing failures before they happen is always more efficient than responding after they occur.

With the right tools and visibility, construction companies can reduce downtime, extend equipment life, and keep every project running on schedule and within budget.

Get maximum results from your assets

Request a demo

Conclusion

Whether it is a crawler crane on a barge or a fleet of loaders on a construction site, every case leads to the same insight: maintenance choices directly influence project performance. Reactive repairs may restore operations, but they do not prevent future failures or address underlying issues. Preventive strategies, supported by accurate data and digital tools, enable construction companies to plan, safeguard their assets, and maintain consistent productivity.

By combining structured maintenance planning with intelligent systems like

FirstBit ERP, construction teams can connect day-to-day operations with long-term reliability, achieving both efficiency and sustainability across their projects.

F.A.Q.

What is the real difference between breakdown and preventive maintenance?

Breakdown maintenance, also called reactive maintenance, happens when equipment is repaired only after it fails. It often means unplanned downtime, urgent repairs, and disrupted schedules.

Preventive maintenance, on the other hand, is planned in advance. It involves regular inspections, servicing, and part replacements to keep equipment running smoothly and avoid sudden failures.

In construction, the difference is clear: one stops work unexpectedly, while the other keeps projects moving without interruptions.

How does preventive maintenance management improve project profitability?

Preventive maintenance turns maintenance from a cost into a safeguard for profit. It reduces expensive emergency repairs, helps equipment last longer, and keeps projects running on schedule. For example, a well-maintained excavator can operate two to three times longer, while timely servicing can cut parts and labor costs by up to half.

It also improves future planning. With accurate maintenance records, contractors can estimate equipment costs more precisely when bidding for new projects, protecting margins and reducing financial surprises.

Can FirstBit ERP help me implement a preventive maintenance system?

Yes. FirstBit ERP is built to simplify preventive maintenance for construction equipment. You can automate service schedules based on time, usage, or project milestones, and assign tasks directly to mechanics or subcontractors when maintenance is due.

The system also tracks spare parts, costs, and inventory, linking every maintenance activity to your project budget. With built-in reports, you can see which machines are the most expensive to maintain and understand the reasons behind them.

In short, it replaces scattered spreadsheets and missed reminders with a clear, organized maintenance process that keeps your equipment reliable and your projects on track.

Which one actually costs more: breakdown or preventive maintenance?

Breakdown maintenance typically costs three to five times more than preventive maintenance. Emergency repairs often mean paying higher labor rates, working overtime, and facing project delays that can lead to penalties or lost revenue. In some cases, a single equipment failure can stop an entire site.

Preventive maintenance might look like an added expense, but in reality, it is an investment. Regular servicing prevents costly breakdowns, keeps schedules on track, and pays for itself through reduced downtime and smoother operations.

Keep equipment in the best condition

Monitor equipment warranties and certifications

Request a demo

Anna Fischer

Construction Content Writer

Anna has background in IT companies and has written numerous articles on technology topics.