On a construction project, money moves quickly, and so do materials. Without a clear process for ordering, it is easy to lose track of what was bought, at what price, and whether it matched the budget.

Purchase orders solve this by turning every purchase into a documented agreement on scope, quantity, price, and delivery terms before any work starts. In this article, we explain what a purchase order is in construction, how it differs from invoices and contracts, what it should include, and how project management tools can help automate the purchase order process and control the whole workflow..

What Is a Purchase Order in Construction?

A purchase order (PO) in construction is a formal document issued by the buyer to the seller, specifying the materials, services, or equipment needed for the project. It sets clear expectations for both parties, including the price, quantity, and delivery terms, ensuring everything is agreed upon before the work begins. This minimizes the chance of misunderstandings and helps both sides stay on the same page throughout the transaction.

Purpose of a Purchase Order in Construction

In construction, a purchase order helps both the buyer and seller confirm exactly what is being bought and at what price. It prevents confusion by outlining agreed-upon quantities and delivery schedules. The PO also protects both parties by providing a clear record of the terms, so everyone knows what to expect, and it can be used to resolve any disputes that might arise later.

Who Issues and Receives a Purchase Order

Typically, the project owner or general contractor issues the purchase order. The buyer clearly outlines what is needed and sends the PO to the supplier or subcontractor. Once the order is placed, the contractor reviews it to confirm they can meet the terms, including quantities and delivery deadlines.

Key Components of a Construction Purchase Order

A construction PO needs enough detail for both parties to clearly understand what is expected. These components help keep the order complete, accurate, and easy to verify.

Detailed List of Deliverables

The PO should list every material, piece of equipment, or service being ordered. This often includes specifications such as size, grade, brand, or performance requirements. Clear descriptions reduce the chance of receiving the wrong product and make it easier for the supplier to prepare the order correctly.

Quantity of Deliverables

Each line item must show the exact quantity required. Accurate quantities help with inventory planning on the buyer’s side and production or stock checks on the supplier’s side. This prevents shortages, oversupply, and last-minute adjustments.

Price Agreement

The price agreement outlines the cost for each item or service. It may also include bulk pricing, taxes, or additional charges. By documenting the final agreed price, both sides avoid billing disputes and have a clear reference when the invoice arrives.

Payment Terms

Payment terms explain how and when the supplier will be paid. This might include deadlines such as Net 30, accepted payment methods, or conditions for partial payments. Clear terms help align expectations and keep the payment process predictable.

Delivery Deadlines

Construction schedules depend heavily on timely deliveries. The PO specifies when materials or services must arrive so work can proceed without delays. This section helps the supplier plan transportation and ensures the buyer receives materials when they are actually needed.

Delivery Method

The PO should also clarify how the materials will be shipped and who is responsible for transportation costs and risks. Terms like FOB Origin or FOB Destination determine at which point the responsibility for the shipment transfers from the supplier to the buyer.

Tracking Numbers

Tracking numbers make it easier for both sides to monitor shipments as they move through the supply chain. Having these identifiers on the PO helps the project team spot delays early and quickly address missing or incorrect items.

Reduce costs and avoid shortages

Optimize procurement with FirstBit

Request a demo

Difference Between a Purchase Order, Invoice, and Contract

Purchase orders, invoices, and contracts work together in construction. However, they each play a different role in the project’s paperwork and cash flow.

Purchase Order vs. Invoice

A purchase order comes first. The buyer issues it to confirm:

- What they want to buy

- In what quantity

- At what price

It is an internal control tool for the buyer and a formal request for the supplier.

An invoice comes later. The supplier issues it after delivering materials or completing work. It is a request for payment that refers back to the PO. On a well-run project, the site team, procurement, and accounts all match the invoice to the original purchase order and delivery notes before releasing payment.

Purchase Order vs. Contract

A contract sets the overall terms of the relationship between parties.

Contract covers:

- Scope

- Pricing structure

- Risk allocation

- Timelines

- Legal obligations for the project as a whole

Purchase orders sit inside that framework. Each PO authorizes a specific package of work, materials, or services under the rules already set by the contract.

On most jobs, the contract answers “how we work together,” while the PO answers “what we are buying this time.”

Benefits of Purchase Orders in Construction

When purchase orders are used consistently, they become a practical tool for cost control and coordination rather than just another document to file.

Clear Scope and Cost Control

A structured PO process forces the team to define quantities, specifications, and prices before committing to a supplier. This reduces “off-the-cuff” purchases, limits scope creep, and gives project managers a clearer picture of committed costs versus budget at any point in time.

Legal and Financial Protection

Because a purchase order records what was ordered, at what rate, and on which terms, it gives both sides something solid to lean on if there is a dispute about quality, quantity, or price. It also creates a clean audit trail for internal reviews, external auditors, and lenders who want to see how project money is being spent.

Project Tracking and Accountability

With purchase orders in place, it becomes much easier to track what has been ordered, what has been delivered, and what is still outstanding. Site teams can plan work around confirmed deliveries, finance can forecast cash needs based on committed POs, and management can see which suppliers perform reliably. Over time, this improves accountability across the entire project supply chain.

Build reliable partnerships with suppliers

Request a demo

How First Bit Automates the Entire Purchase Order Cycle for Construction Projects

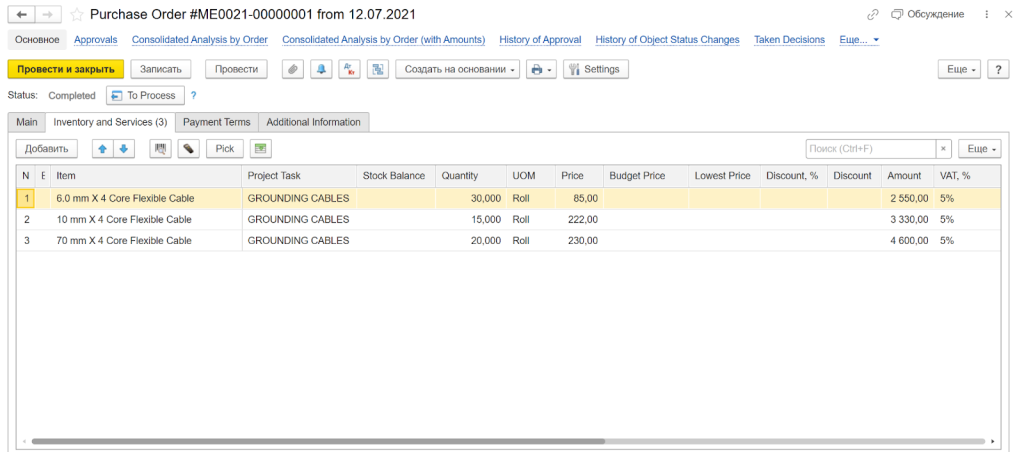

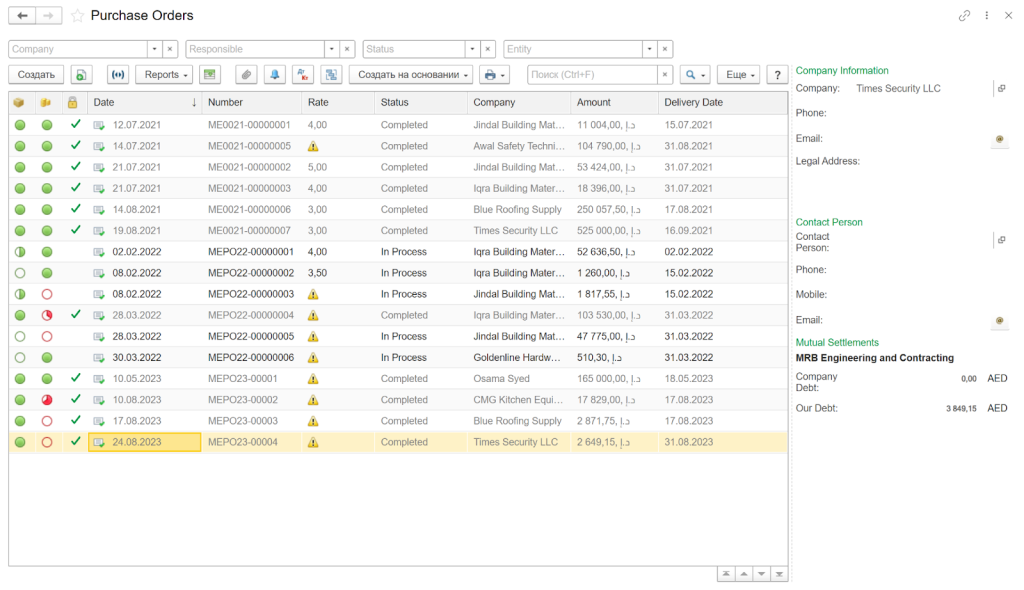

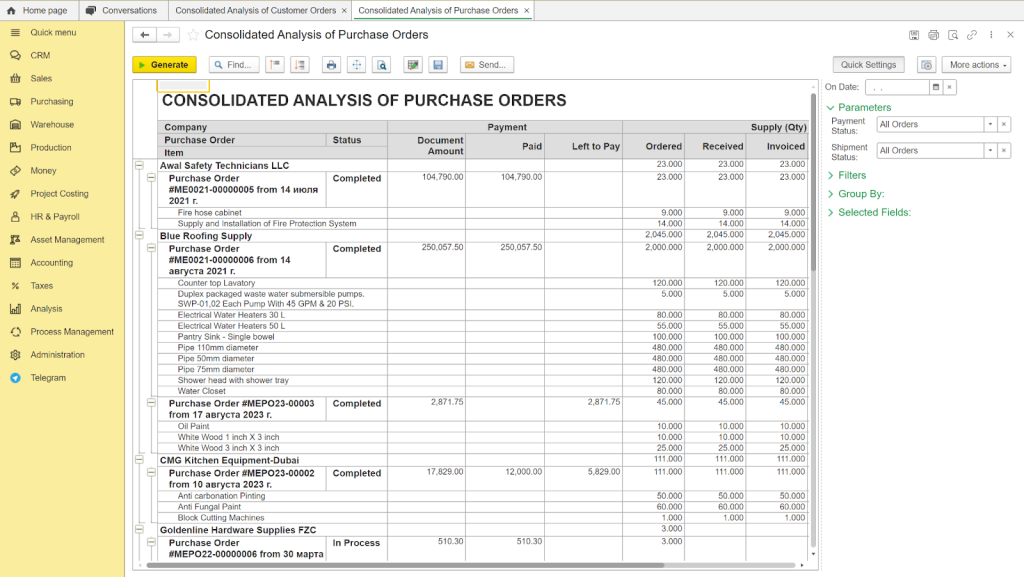

FirstBit ERP connects every stage of the purchase order workflow so project teams can manage procurement without jumping between spreadsheets, messages, and paper forms.

- Streamlined PO creation and approvals. That’s how project managers can build purchase orders directly from estimates, BOQs, or material requests. Quantities and prices pull in automatically, reducing manual entry.

- Real-time delivery and status tracking. This means that once a PO is issued, FirstBit ERP tracks every step: confirmations from suppliers, shipment details, delivery notes, and partial receipts. Site teams can log received quantities on the spot, while office staff see updates instantly.

- Full integration with budgeting and cost control. Every purchase order updates the project budget in real time. Committed costs, delivered quantities, and remaining balances are visible across the system.

The approval chain is built into the system, so supervisors or finance teams review and sign off digitally before the order goes out to the supplier.

This helps project managers avoid overspending, improves cash-flow planning, and gives company leadership a clear view of financial exposure across all active jobs. This minimizes errors and prevents materials from arriving unannounced or going missing.

Conclusion

A purchase order may seem like a simple document, but in construction, it plays a bigger role than most people realize.

When used consistently and supported by the right digital tools, POs become a backbone for cost control, scheduling, and supplier coordination. Clear documentation removes guesswork, real-time tracking reduces delays, and automated workflows keep teams aligned even when project pressure rises.

As the industry moves toward more structured, data-driven management, companies that build disciplined PO processes today will run smoothly, reduce waste, and deliver stronger results across every project.

Align every purchase with project goals

Track supplier performance and control costs

Request a demo

F.A.Q.

Why are purchase orders important in construction?

What information should be included in a construction purchase order?

How is a purchase order different from an invoice?

Anna Fischer

Construction Content Writer

Related terms

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.