Construction is one of the largest capital-intensive industries on earth. It’s valued at $11.39 trillion in 2024 and forecast to hit $16.11 trillion by 2030.

[?] Yet despite these staggering figures, much of that money is tied up in construction assets that are either under-managed or under-utilized. Among these assets are heavy machinery, vehicles, tools, materials, and partially completed structures. For many contractors, this isn’t an abstract problem; it’s an issue that costs a lot of money.

Idle equipment, untracked inventory, delayed maintenance, or inaccurate asset records can eat up 5–10% of a project’s budget. These hidden costs often wipe out profit margins that are already razor-thin.[?]

If you’ve dealt with sudden equipment breakdowns, missing tools, or budget overruns from poorly tracked assets, you’re not alone. This article explains what construction assets are, why they matter for your project’s bottom line, and how better management practices can transform a construction project from costly overhead into a real competitive advantage.

What Is a Construction Asset?

A construction asset refers to any resource — tangible or intangible — that a construction company owns, leases, or controls. It also has measurable value and is used to deliver construction projects.

This goes beyond just cranes and trucks. It includes:

-

Heavy machinery

-

Vehicles

-

Tools

-

Materials

-

The land and buildings used

-

Intangible items (e.g., specialized software, design models, or patents)

If it directly or indirectly supports scheduling, building, and managing construction work and has value that can be lost, wasted, or degraded, it qualifies as a construction asset.

Over time, such assets depreciate. They lose value due to wear and tear, technological obsolescence, or simply aging. For example, many construction firms use equipment over useful lives of 5-7 years, depending on the type. After that, the depreciation dramatically reduces their economic value.[?]

Reasons To Classify Construction Assets

Every construction project involves a wide variety of assets. Each of them has different lifespans, uses, costs, and maintenance needs. Without a clear system for classifying these assets, companies can lose control over financial reporting, operational efficiency, and long-term planning.

Here is why it is important to classify construction assets properly:

1. Improved Financial Reporting

When you classify your assets, your financial statements (like balance sheets) are clearer. You know exactly what machinery, buildings, tools, etc., you own and how much they are worth. Businesses that report this way often show better trust with banks or partners.

Proper classification of construction assets isn’t just good practice; it’s required by accounting rules like IAS 16 (Property, Plant & Equipment) under

IFRS. These standards ensure companies separate tangible assets (like machinery and buildings) from intangible ones (like software or licenses).

IFRS also requires that you measure assets correctly and disclose details such as depreciation methods, useful lives, and carrying amounts. This makes financial statements more reliable, transparent, and compliant for investors, auditors, and regulators.

2. Calculation of Depreciation

Depreciation means lowering the value of an asset bit by bit as it gets older or is used. If you correctly classify your assets, you can apply the right depreciation rules. For example, heavy machines lose value faster than land or buildings.

Using correct depreciation helps you know how much to charge as an expense each year. It also affects taxes and profit.

3. Strategic Planning

Once you know what assets you have, what condition they are in, and how old they are, you can plan better. You can decide which machines to replace, when to buy new ones, or whether you need more storage space, etc.

For example, if lots of your heavy equipment is old, maintenance costs may keep increasing. If you see that, you can budget to buy newer assets at better times or lease instead of buying. This will help avoid surprises in your project budgets.

4. Risk Management

Construction work has many risks. Assets can break, get stolen, require repairs, turn unsafe, or become non-compliant with safety rules. If you classify assets well, you know which ones need special inspections or safety checks.

Theft is a big issue: surveys find that about 92% of construction companies have experienced theft of assets, and 21% say theft is a weekly problem.[?]

Also, knowing the value and type of assets helps with insurance: you insure only what you need, not over-insure or under-insure. If something happens (fire, damage), you can estimate losses and recover more effectively.

Extend equipment lifecycle

Schedule maintenance and avoid downtime with FirstBit

Request a demo

Main Types of Construction Assets

Understanding the main types of construction assets will help you organize them more effectively. This knowledge will also improve your ability to manage their maintenance, utilization, and eventual disposal.

Now, let’s explore different types of construction assets.

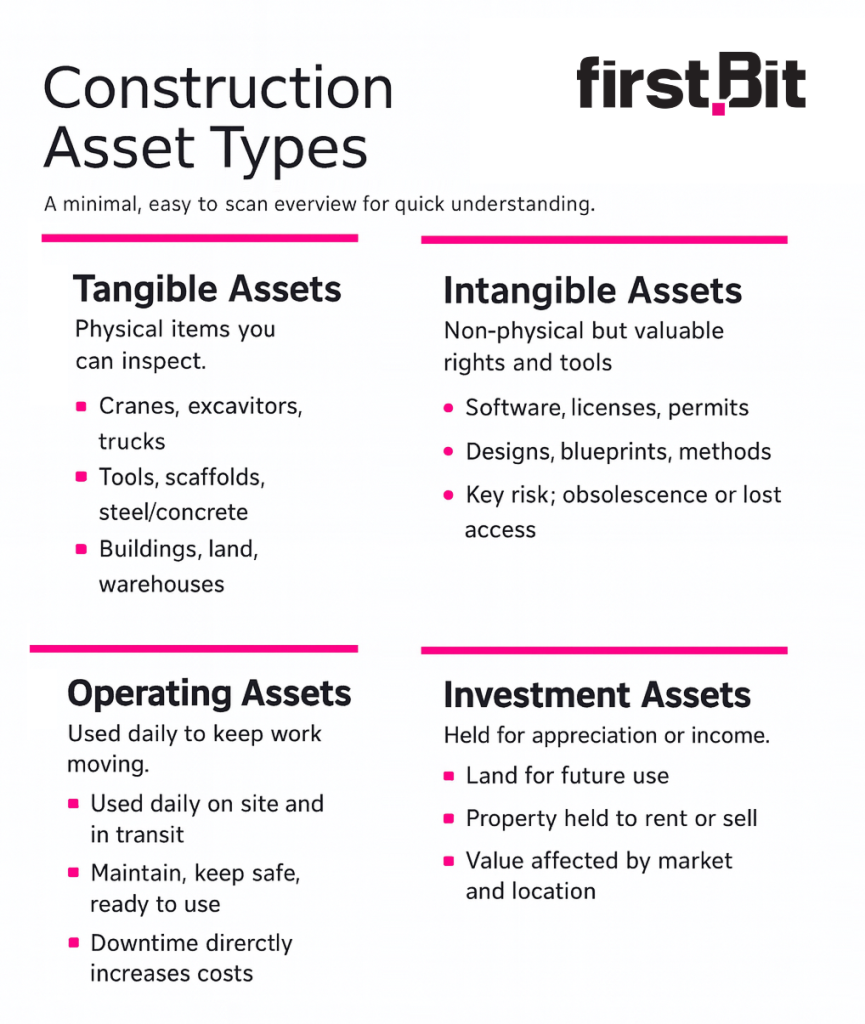

Tangible Assets

These are physical things you can touch. For example:

-

Heavy machinery (cranes, excavators)

-

Vehicles (trucks)

-

Tools, scaffolding, steel, and concrete

-

Buildings, land, warehouses

These assets wear out, break, or lose value. You can inspect them visually and track their condition.

Intangible Assets

These are non-physical assets. You can’t touch them, but they still have value. Examples include:

-

Software for planning, design, or accounting

-

Licenses, patents, rights, and permits

-

Designs, blueprints, or special construction methods

They often cost less to maintain physically. However, losing them or having them become obsolete can also cause big problems. For example, software that’s no longer supported can disrupt your operations or force you to make expensive replacements.

Operating Assets

These are assets used every day to run a construction project. For example:

-

Machines you always use on the site.

-

Tools you move between tasks and locations.

-

Vehicles that transport materials.

These assets must be maintained, kept safe, and ready to use. Downtime, when they are broken or unavailable, can cost a lot.

Investment Assets

These assets are not just for daily use. Their value increases over time. Examples:

-

Land bought for future projects.

-

Buildings or property that you do not use, but may rent out or sell later.

-

Financial investments linked to construction assets.

These may not wear out quickly, but their value can change because of factors like location, market conditions, regulation, etc.

Best Practices for Managing Construction Assets

Having good rules and habits helps you manage assets effectively and keep costs low. Here are some of the best practices:

1. Create and Maintain an Asset Inventory

An inventory is a list of all assets:

-

What they are

-

Where they are

-

When you got them

-

How much do they cost

This helps you know exactly what you own. Companies without accurate inventories lose money because they buy more than needed, and duplicate items as a result, or can’t find what they already have.

2. Assign Tags and Labels

Put tags (barcodes, QR codes) or labels on assets. Then you can scan or track them easily. It’s like putting name tags on your own tools. For example, if your drill is tagged, you can use a phone or scanner to see when it was last used or maintained. This reduces loss, theft, or forgetting maintenance.

3. Maintain an Asset Register

This is like a book or software system that records details about every asset:

-

Value

-

Purchase date

-

Condition

-

Maintenance record

-

Location

With a good register, when you write financial reports or calculate depreciation, you can base them on accurate data. It also helps you track when an asset needs to be replaced.

4. Integrate Asset Management Tools

Nearly 70% of construction firms confessed in a recent survey that they still operate without a central system to track and optimize their assets.

[?] The results can include:

-

Costly downtime

-

High insurance premiums

-

Unchecked depreciation

-

Serious safety risks

All of this can snowball into multi-million-dollar losses and shattered project timelines. That’s why it is best to use tools or ERP software to track assets, schedule maintenance, monitor costs, and generate reports.

With good ERP, field and office teams can see the same data, reducing mistakes. This reduces mistakes and keeps everyone aligned. For example,

FirstBit ERP has a mobile app that enables you to update reports on the go.

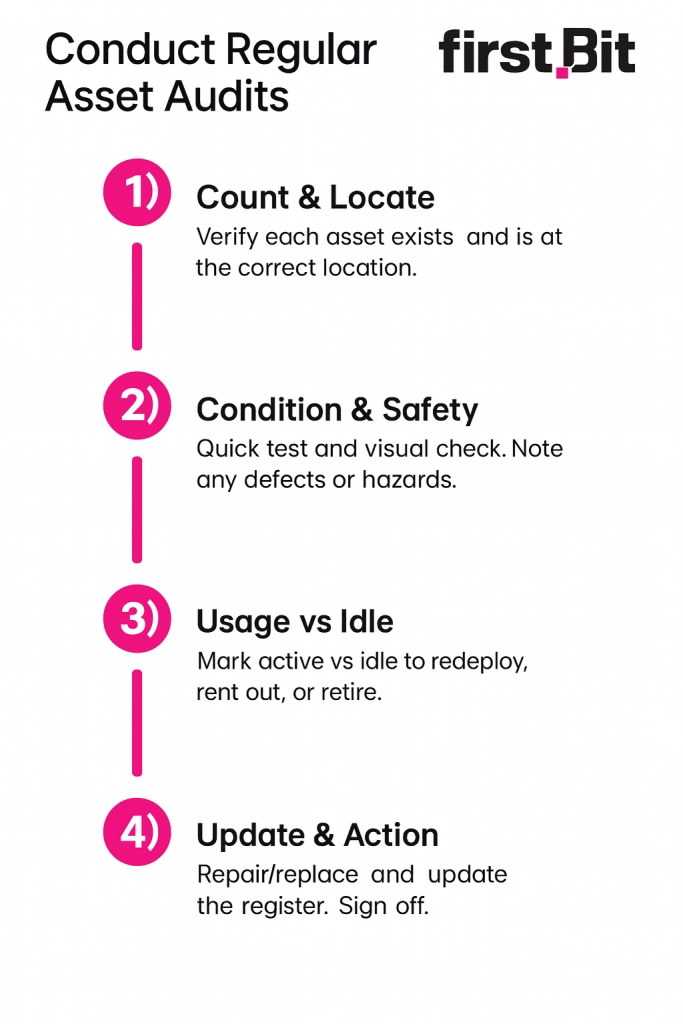

5. Conduct Regular Audits

Check assets periodically. Ask:

Audits help you notice mistakes, missing items, or broken things you forgot to repair. This way, you can fix issues easily and avoid big replacement costs.

How to conduct regular asset audits

Keep your equipment running smoothly

Request a demo

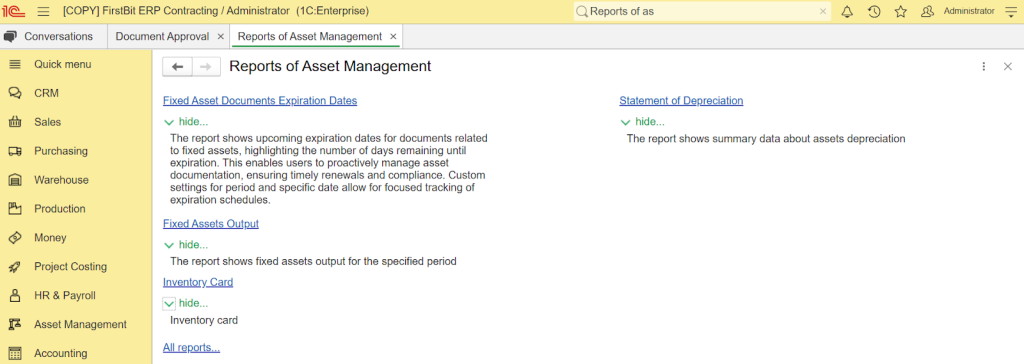

How FirstBit ERP Transforms Construction Asset Management

Here’s how

FistBit ERP helps make managing all construction assets much easier:

-

Centralized data and real-time reporting. Instead of having different spreadsheets in different offices, you have everything in one place. So you always know the status, cost, and condition of assets. FirstBit ERP gives you data from dashboards and real-time reports, so you can see if a project is going off budget before it’s too late.

Reports of asset management in FirstBit ERP

-

Project cost tracking. You can track how much each asset (machine, tool, etc.) costs you to operate: maintenance, fuel, and repair. This helps you decide whether it’s better to replace or continue using it.

-

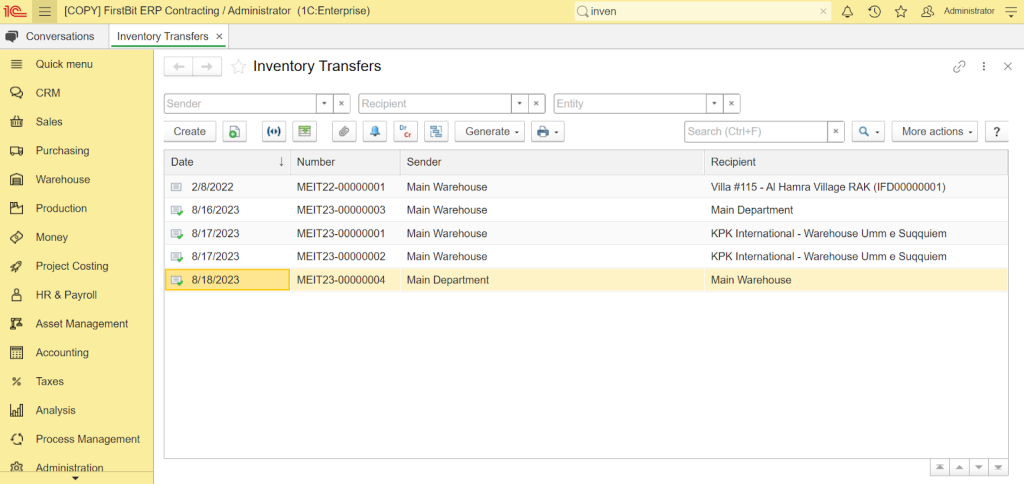

Inventory and procurement control. FirstBit allows you to see what materials and spare parts you have, what’s been ordered but not delivered, and what’s in use. This reduces waste, duplication, and buying too many things.

Inventory transfers in FirstBit ERP

-

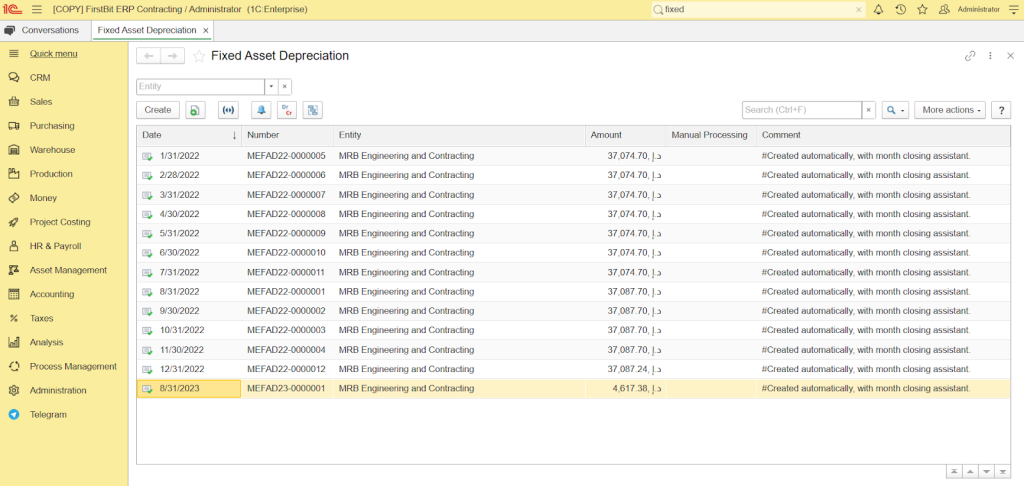

Depreciation and financial compliance. It lets you record the purchase date, cost, useful life, and condition, so that depreciation calculations are correct. This way, when accountants or auditors ask, the numbers are ready.

Fixed asset depreciation in FirstBit ERP

-

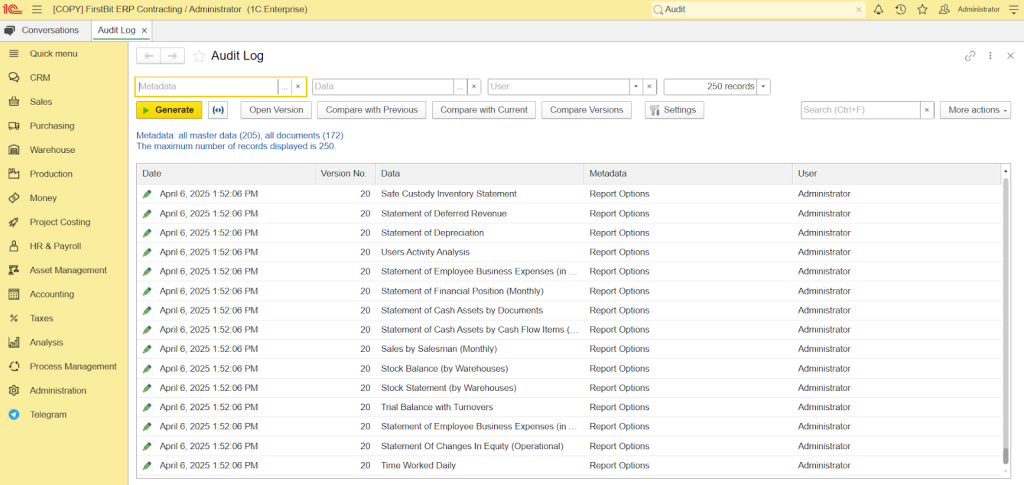

Audit and safety checks. Because assets are logged and tracked, you can schedule safety checks, inspections, and maintenance. If something needs repair, the system flags it. This reduces sudden failures.

Audit log in FirstBit ERP

With these tools, FirstBit ERP helps companies avoid lost time, reduce costs, avoid surprises, and use assets efficiently. As a result, profits are better and risks are lower.

Conclusion

If you want to effectively manage construction assets, you need to implement a complex system of practices into your workflow. Keep inventories updated, use asset-tagging systems, maintain an asset register, conduct regular audits, and leverage ERP software. For example,

FirstBit ERP can provide visibility into the status of your assets, reduce waste, improve safety, and boost profits.

Get maximum results from your assets

Optimize resources with FirstBit

Request a demo

FAQ

Why are construction assets important?

They are important because without them, you can’t build things. If your machines don’t work, you don’t have tools, or your designs or software are bad, work slows down, costs rise, and quality drops. Assets are big investments, so managing them well protects profits and safety.

What are examples of physical construction assets?

These are some examples: excavators, cranes, trucks; tools like drills, hammers, and saws; scaffolding, steel beams, concrete mixers; buildings, warehouses, and land.

What are examples of digital construction assets?

These are non-physical, for example: software you use for project planning, accounting, and design (like CAD); licences or permits; digital models or blueprints; proprietary methods or processes stored digitally.

How can construction companies manage their assets effectively?

Make a full list (inventory) of all assets. Tag assets so you can track them (barcodes, QR codes). Use a register/system that records purchase, cost, condition, and maintenance. Use software or ERP so everyone sees the same data, and reports are easy. Do regular checks/audits to catch broken, lost, unused, or unsafe assets.

Sumaiya Aslam

Contributing Author

Sumaiya Aslam writes insightful content for construction professionals, sharing practical knowledge, industry trends, and strategies to improve project success and efficiency.