Did you know that nearly 70% of large construction projects experience cost overruns or delays? [?]

One of the biggest culprits is poor vendor selection—choosing suppliers, contractors, or service providers who can’t meet project requirements, exceed budgets, or fail to deliver on time.

If you've ever struggled with unqualified bids, vague proposals, or contractors who overpromise and underdeliver, you're not alone. Many construction firms rely on outdated procurement methods or rush through the RFP process, leading to misaligned expectations, budget blowouts, and project delays. A poorly structured RFP can attract bidders who don’t fully understand your project needs—or worse, ones who undercut prices just to win the contract, only to later hit you with change orders and unexpected costs.

This is why a well-crafted RFP is critical. It helps you define your needs clearly, filter out unqualified vendors, and select the right partner for your project—ensuring that timelines, quality standards, and budgets stay on track. In this article, we’ll break down how RFPs streamline procurement, what makes an effective RFP, and best practices to avoid costly mistakes.

Why are RFPs Important in Construction Procurement

Whether you're managing your first construction project or looking to improve your procurement process, understanding how RFPs work will help you select the right contractors.

1. Easier Comparison and Evaluation

A well-structured RFP process offers several key advantages. First, it allows organizations to receive proposals that are easily comparable since all potential contractors are responding to the same set of requirements.

This standardization makes the decision-making process much more straightforward and objective. The clear structure also saves significant time during the selection process, as there's no need for multiple rounds of clarifying questions and discussions.

2. Transparency and Risk Management

Furthermore, this approach ensures complete transparency and fairness in the selection process, which is particularly important for government and large corporate projects.

Perhaps most importantly, having detailed requirements laid out from the start helps prevent misunderstandings that could lead to problems later in the project.

3. Common Applications

You'll find RFPs being used across many different industries and situations. They're particularly common in government contracting, where transparency and fair competition are legal requirements. Large corporations frequently use RFPs for significant projects or purchases to ensure they're getting the best value for their investment.

4. Industry-Specific Usage

The construction industry relies heavily on RFPs for both public and private projects. In the technology sector, RFPs are standard practice for major IT development projects.

Professional service firms often encounter RFPs when organizations are seeking consulting, accounting, or legal services. Any situation involving large-scale purchases or complex services typically benefits from using the RFP process.

5. Fair Competition

RFPs serve as a cornerstone in construction project management, offering multiple critical benefits. At its core, an RFP creates a level playing field where all potential contractors have an equal opportunity to compete.

By establishing uniform evaluation criteria it eliminates bias and ensures selections are based purely on merit, experience, and capability.

6. Defined Project Scope

The process begins with a clearly defined project scope, which sets precise expectations and prevents misunderstandings from the start.

This detailed outline helps contractors understand exactly what's required, allowing them to accurately estimate resources, timelines, and costs while avoiding scope creep during execution.

7. Qualification Assessment

Through RFPs, project owners can thoroughly evaluate contractor qualifications, examining everything from past projects and technical expertise to team capabilities.

This comprehensive assessment includes reviewing contractors' financial stability, commitment to safety, and sustainable practices. Contractors, in turn, can showcase their unique strengths, whether that's innovative methodologies or proprietary technologies.

8. Cost Transparency

Financial transparency is another crucial advantage of the RFP process. By requiring detailed cost breakdowns, project owners can better plan their budgets and compare proposals effectively.

This transparency helps identify contractors who offer the best value while reducing the risk of unexpected expenses during the project.

9. Risk Management

Perhaps most importantly, RFPs serve as a risk management tool. They require contractors to identify potential challenges upfront and explain their strategies for addressing them.

For better risk management, FirstBit ERP system automatically flags high-risk vendors based on predefined criteria such as financial stability ratings, compliance violations, and past performance issues.

Stay ahead of delays

Monitor project progress with FirstBit

Request a demo

Creating an Effective Construction RFP

The success of any construction project begins with a well-structured request for proposal process. Let's break down how to create a document that attracts qualified contractors and sets your project up for success.

1. Foundation Elements

Start with an engaging executive summary that captures attention and presents your organization's story concisely. This introduction serves as your project's first impression, highlighting its unique aspects and value proposition.

Follow this with a detailed project description that transforms your vision into clear, actionable requirements.

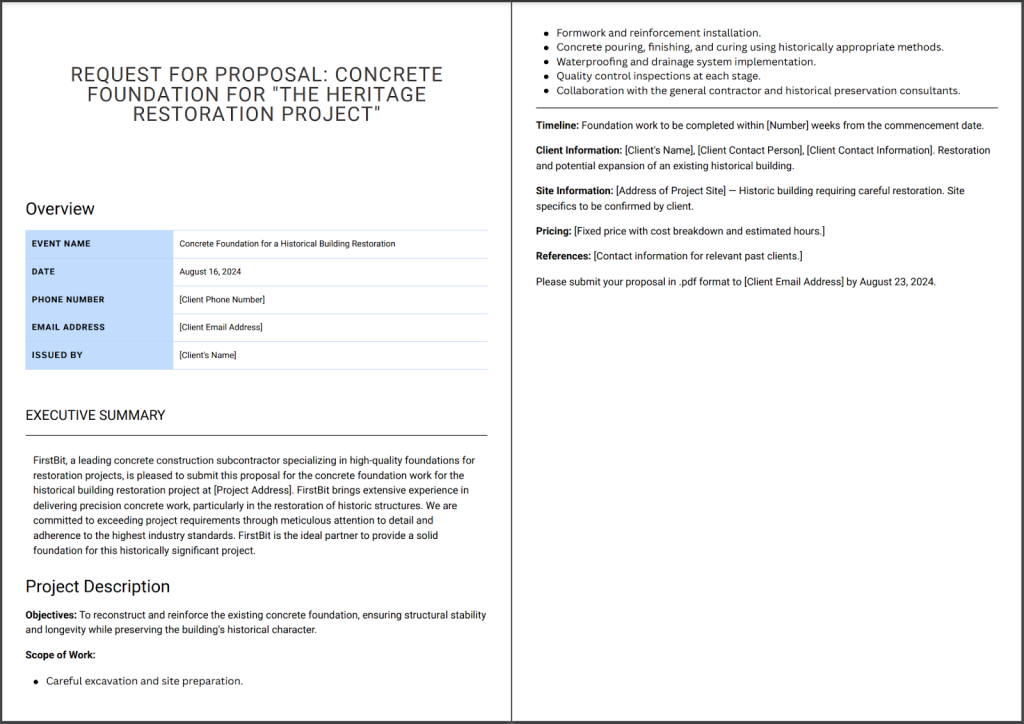

Here’s an example of an effective RFP, complete with all the elements discussed in the sections below:

2. Core Components

Your RFP should clearly define scope boundaries, leaving no room for misunderstanding. Break down the project into specific tasks and responsibilities, detailing exact requirements for deliverables, methods, and materials.

For example, instead of general statements like "build according to standards," specify "construct using grade-A materials following local building codes XYZ."

3. Timeline and Evaluation Framework

Build your project timeline strategically, working backward from the desired completion date. Include specific milestones, submission deadlines, and selection dates while accounting for potential delays.

Establish transparent evaluation criteria, breaking down your scoring system into specific categories like cost (30%), experience (25%), technical approach (25%), and timeline (20%).

4. The Selection Process

Guide contractors through a thorough review process, encouraging comprehensive proposals that demonstrate understanding and highlight unique qualifications. Support this phase with organized site visits and clear expectations for subcontractor involvement. Maintain transparent communication throughout, from initial submission to final selection and contract negotiation.

5. Submission Guidelines

Create a clear path for contractors to provide exactly what you need. Outline required proposal sections, specify formats, and set firm deadlines. Consider providing a proposal checklist to ensure all required elements are included, saving time for both parties while improving proposal quality.

Common Challenges in the RFP Process

While the RFP process provides a structured approach to contractor selection, organizations often face several common obstacles along the way. Being prepared for these challenges helps procurement teams develop more effective strategies and avoid potential pitfalls.

1. Inaccurate Specifications

One of the most frustrating challenges is getting specifications right. Even experienced teams can miss critical details or include ambiguous requirements. Technical specifications might become outdated during the RFP development process, or stakeholders might realize too late that certain requirements were overlooked. Sometimes, departments provide conflicting information, leading to confusion in the final document.

How to overcome: Create a detailed specification checklist and have multiple stakeholders review it independently. Schedule regular alignment meetings with technical teams and end-users to verify requirements. Document all specification changes and ensure they're communicated across all relevant RFP sections.

Pro tip: Maintain a living document of specification errors from past RFPs to create a "common pitfalls" reference guide for future projects.

2. Time Constraints

RFP timelines often face pressure from multiple directions. Senior management might push for faster completion, while technical teams need more time for accurate specifications. Holidays, internal approval processes, and competing projects can create unexpected delays. Rush jobs frequently lead to overlooked details and costly mistakes.

How to overcome: Build your timeline with a 20% buffer for unexpected delays. Start gathering requirements and stakeholder input well before the official RFP development begins. Break the process into smaller, manageable deadlines rather than one final due date.

Pro tip: Create a standard RFP development calendar template that includes all typical review and approval steps, making it easier to plan realistic timelines for future projects.

3. Vendor Misunderstandings

Even well-written RFPs can be interpreted differently by various vendors. Technical terms might have different meanings across industries or regions. Vendors might make assumptions about unstated requirements based on their previous experiences. Sometimes, they might overlook critical details buried in lengthy documents.

How to overcome: Host a mandatory pre-bid conference where vendors can ask questions directly. Create a structured Q&A process and share all questions and answers with all bidders. Consider creating an RFP summary document that highlights key requirements and potential areas of misunderstanding.

Pro tip: After each RFP process, collect feedback from both successful and unsuccessful bidders about what was unclear in your RFP. Use this information to improve future documentation.

Keep your project on track

Request a demo

Best Practices for Crafting Effective RFPs

Crafting an effective RFP requires careful planning and attention to detail. Here are six key practices that can significantly improve your RFP outcomes.

1. Define the Problem, Not Just the Solution

Best practice begins with clearly articulating your business challenge rather than prescribing specific solutions. Write problem statements that focus on desired outcomes and business objectives.

For instance, instead of specifying "implement a cloud-based inventory system," describe "reduce inventory tracking time by 50% while improving accuracy to 99%." This approach invites innovative solutions that might better serve your needs.

2. Include Background and Project Context

Successful RFPs provide comprehensive context that helps vendors understand your situation fully. Include relevant information about your organization's size, industry position, current systems, and future goals. This context enables vendors to propose more targeted solutions and demonstrate how their approach aligns with your specific needs.

3. Structure Your RFP for Clarity and Engagement

Organize your document with a clear, logical flow that guides vendors through your requirements. Use consistent formatting, numbered sections, and clear hierarchies.

Include a detailed table of contents and ensure each requirement is clearly labeled as "mandatory" or "preferred." This structured approach helps vendors provide more accurate, complete responses while making your evaluation process more efficient.

4. Encourage Vendor Creativity and Alternative Solutions

While maintaining clear requirements, include specific sections where vendors can propose innovative approaches or alternative solutions. Create opportunities for vendors to showcase their expertise by including questions like "What alternative approaches might you suggest to achieve our objectives?" This flexibility often leads to discovering more effective solutions than initially envisioned.

5. Request Case Studies, References, and Past Performance Proof

Make informed decisions by requiring concrete evidence of vendor capabilities. Request detailed case studies of similar projects, complete with measurable outcomes and lessons learned. Specify the type of references you need and what questions you'll ask them. This validation helps ensure vendors can deliver on their promises.

6. Review, Refine, and Improve Your RFP Process

Treat your RFP process as a living document that evolves with each project. Establish a formal review process to capture lessons learned and best practices. Regularly update your templates and evaluation criteria based on past experiences and changing business needs. This continuous improvement approach leads to more effective RFPs over time.

7. Stakeholder engagement

Effective stakeholder engagement throughout the RFP process ensures that all parties have a clear understanding of the project requirements and helps minimize misunderstandings or conflicts during the construction phase. Essential stakeholder engagement practices include:

-

Encouraging open communication between project owners and potential bidders

-

Providing a platform for potential bidders to ask questions and seek clarifications

-

Allowing for productive discussions to ensure a better understanding of project requirements

-

Promoting collaboration between all parties involved in the RFP process

8. Consistent communication

Maintaining consistent communication and providing regular updates throughout the RFP process ensures transparency and allows for timely adjustments when necessary. A well-structured feedback system helps identify potential issues early in the process and enables continuous improvement of the RFP process.

Key aspects of updates and feedback include:

-

Implementing a systematic approach for tracking and documenting all inquiries

-

Providing regular updates on the RFP status and evaluation process

-

Creating opportunities for bidders to receive feedback on their submissions

-

Establishing a systematic approach for tracking and responding to inquiries

The important thing for you is that the RFP process is not just about selecting a contractor; it's about building relationships and establishing clear expectations that will carry through the entire project lifecycle.

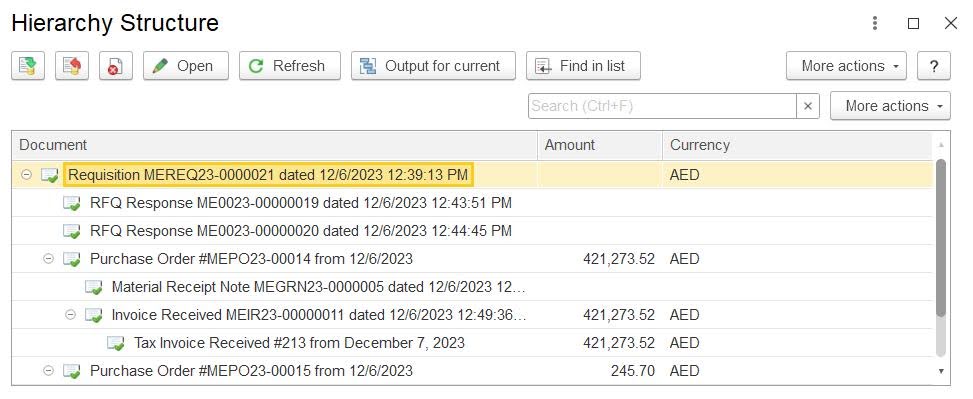

How FirstBit ERP Can Enhance RFP Management in Construction

ERP systems serve as a central hub where all RFP-related information and activities can be managed efficiently. That’s how FirstBit ERP helps organize and store all documents in one place, making it easy for team members to access and update proposal information whenever needed.

One of the biggest advantages of using ERP systems for RFPs is their ability to connect different parts of the construction business. They bring together important information about costs, available resources, and project schedules, which helps in creating more accurate and comprehensive RFPs.

The reporting capabilities of the FirstBit ERP system will help you make better decisions when reviewing proposals. The system offers analytics tools that transform raw proposal data into actionable insights. With FirstBit's customizable reporting features, you can easily generate comparative analyses of vendor submissions, examining key metrics such as pricing structures, delivery timelines, and past performance records. The system's built-in dashboards provide visual representations of proposal data, making it simple to identify trends and potential risks.

Boost project performance

Assign the right people to the right tasks

Request a demo

Anna Fischer

Construction Content Writer

Related terms

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.