For most businesses, implementing an ERP system is a major milestone. But what often gets overlooked is what comes next — keeping that system healthy, responsive, and aligned with evolving business needs. ERP maintenance isn’t just a technical task; it’s an ongoing strategy that protects your investment, prevents system slowdowns, and ensures you’re getting maximum value from your software.

Too often, companies invest heavily in ERP implementation only to overlook the long-term upkeep required to keep it running efficiently. As usage increases, systems begin to slow, workflows break, and users get frustrated, not because the software is wrong, but because it’s been left behind.

41% of ERP users report usability or performance issues within two years. [?]

This guide outlines what ERP maintenance really means, why it matters, the different types involved, and the most common challenges businesses face with practical, proven strategies to stay ahead.

What Is the ERP Maintenance Process?

ERP maintenance is a structured, continuous process that ensures your system remains reliable, secure, and aligned with your business needs, long after the initial implementation is complete. It’s not a one-time task or a quarterly technical update. Rather, it’s a cross-functional effort involving IT, operations, finance, and project managers to keep ERP software responsive and future-ready.

This process is especially critical for businesses in industries like construction, where delays, miscommunications, or outdated financial data can lead to project overruns, compliance issues, or missed profit targets.

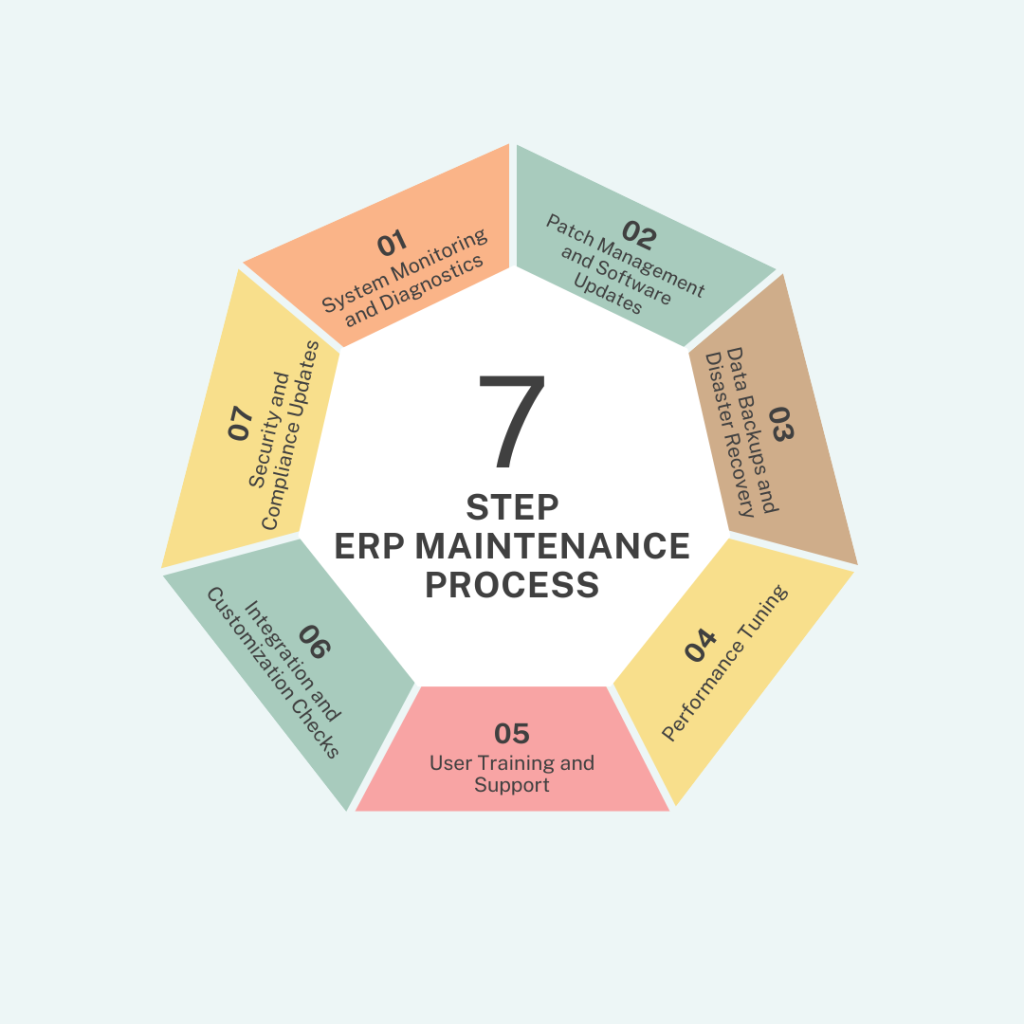

Here’s a breakdown of what the ERP maintenance process looks like in practice:

1. System Monitoring and Diagnostics

The process begins with proactive system monitoring. This involves tracking performance indicators such as response time, server health, failed transactions, and background jobs. Monitoring also includes watching for integration issues between the ERP system and third-party applications such as payroll tools, procurement portals, or field service apps.

Automated alerts, audit logs, and real-time dashboards help IT teams detect early signs of system strain or failures before they affect operations.

For example, if your ERP platform supports multi-site inventory management across several construction projects, regular diagnostics will highlight sync delays, broken reports, or outdated inventory counts — all of which can impact procurement and budgeting accuracy.

2. Patch Management and Software Updates

ERP providers routinely release patches to address security vulnerabilities, correct software bugs, or introduce new features. These patches must be reviewed, tested, and applied as part of a controlled maintenance schedule.

For cloud-based ERP systems, many of these updates are automated. For on-premise or hybrid systems, this step requires planning to avoid conflicts with custom features or third-party tools.

Failing to update ERP software can leave your business exposed to cybersecurity risks or functional bottlenecks.

A common mistake of delaying patches due to fear of “breaking” custom modules is often a sign that customization wasn’t designed with flexibility in mind.

3. Data Backups and Disaster Recovery

A core component of ERP maintenance is ensuring that data is backed up regularly and securely. This includes both master data (customers, vendors, items) and transactional records (orders, payments, project expenses).

Backups should follow best practices:

-

Daily or real-time incremental backups

-

Encrypted storage

-

Offsite or cloud replication

-

Regular restoration tests

Disaster recovery protocols should also be reviewed and updated periodically, covering both system failures and cybersecurity incidents. In industries like construction, where delayed invoicing or payroll can affect project timelines, a failed backup can lead to cascading operational disruptions.

4. Performance Tuning

As more users interact with the ERP system and data volumes grow, system performance naturally begins to degrade. ERP maintenance includes tuning databases, optimizing user workflows, and identifying technical bottlenecks that slow down tasks such as report generation or financial closing.

Key actions during performance tuning include:

-

Archiving historical records that slow down queries

-

Re-indexing databases for faster search

-

Analyzing user behavior to streamline forms, approvals, and dashboards

-

Scaling cloud or server resources to match transaction load

95% of businesses improved some or all of their business processes after implementing ERP.[?]

5. User Training and Support

Maintenance isn’t just about keeping the software up to date — it’s also about ensuring users can work efficiently with every new update, screen, or workflow. Whether it’s a new compliance feature, a revised procurement process, or a dashboard refresh, users need to be trained and supported regularly.

This part of the process includes:

-

Creating and updating SOPs

-

Running department-specific training sessions

-

Establishing a ticketing or support workflow

-

Gathering feedback on usability issues

Ongoing support prevents workflow disruptions, reduces error rates, and encourages employees to embrace new system features rather than revert to manual workarounds.

6. Integration and Customization Checks

Most ERP systems integrate with external tools and include custom modules built to match company-specific needs. These elements often introduce friction when new software updates are applied or when APIs change. As part of maintenance, integrations and customizations must be regularly tested, updated, and documented.

Key checkpoints include:

-

Verifying API connections

-

Testing custom scripts and add-ons after every system update

-

Revalidating data flows between systems (e.g., ERP ↔ payroll)

-

Reviewing whether older customizations are still needed

Without this step, small integration failures can lead to invoice mismatches, inaccurate project costing, or reporting errors that ripple across departments.

7. Security and Compliance Updates

Security is an essential pillar of ERP maintenance. ERP systems store sensitive data including financial records, HR files, project costs, and vendor contracts making them a prime target for cyber threats.

The maintenance process includes:

-

Installing the latest security patches

-

Updating firewalls and endpoint protection

-

Reviewing and adjusting user permissions

-

Testing backup restoration and failover capabilities

-

Keeping audit logs for all critical transactions

Additionally, changes in tax regulations, labor laws, or industry-specific standards must be reflected in ERP system rules and workflows.

Why Is Regular Maintenance Important?

ERP systems are foundational to day-to-day operations. But without regular maintenance, they can become bottlenecks rather than business enablers. Just as machinery needs calibration and servicing to perform efficiently, ERP systems require regular care to deliver the promised return on investment.

1. Prevent Disruptions and Downtime

Unattended bugs, outdated integrations, or overloaded databases can cause system slowdowns or even full outages. These disruptions don’t just impact internal operations — they delay customer orders, payroll runs, and compliance reporting.

2. Extend System Lifespan and Performance

ERP systems represent a significant investment, often running into hundreds of thousands of dollars. Regular maintenance helps extend the useful life of the system, avoids costly re-implementations, and ensures it can adapt as the business grows.

3. Support Regulatory and Security Compliance

As data protection laws and industry regulations evolve, ERP systems must be updated to remain compliant. This includes modifying tax logic, securing sensitive data, and producing traceable audit logs — all achievable through structured maintenance.

4. Optimize User Productivity

When ERP systems are slow or confusing, employees revert to spreadsheets or offline processes, reintroducing the very inefficiencies ERP was meant to solve. Maintenance ensures users always work with the most reliable, intuitive version of the system.

5. Keep Up With Business Change

Markets shift, workflows evolve, and companies scale. ERP maintenance ensures the system remains aligned with current business models, whether that means enabling mobile approvals on job sites or integrating new subcontractor portals into project workflows.

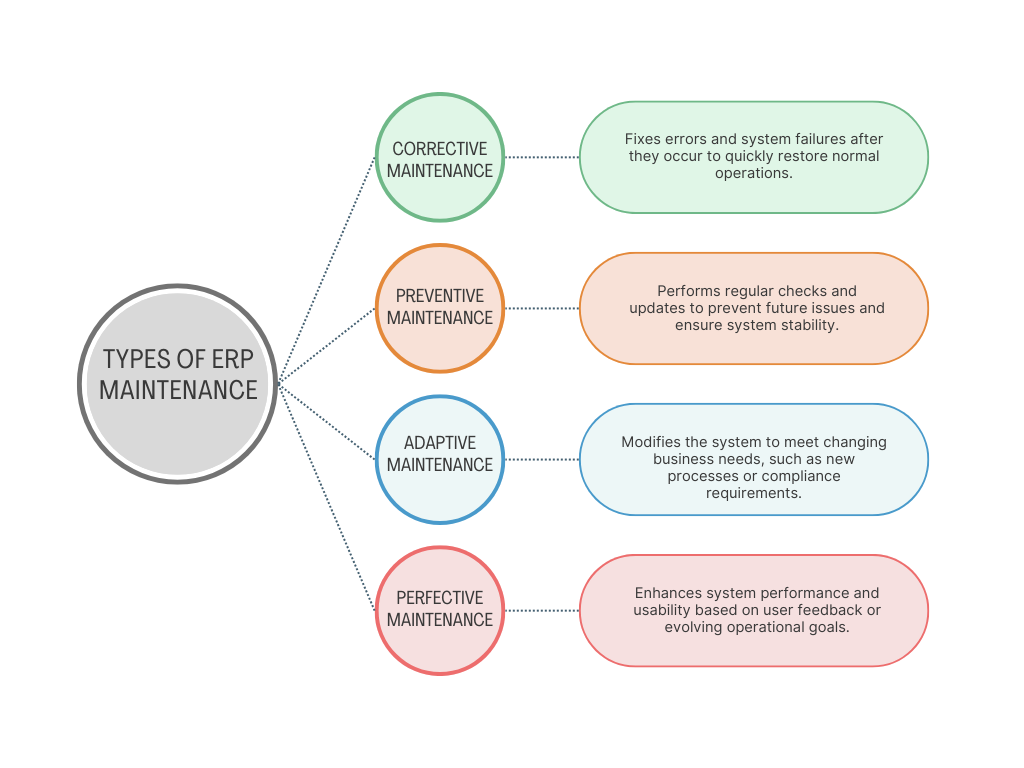

Types of ERP Maintenance

ERP maintenance isn’t one-size-fits-all. Depending on the nature of the issue and the goal of the activity, ERP maintenance can be categorized into four distinct types. Each plays a critical role in ensuring the system remains stable, secure, and effective.

1. Corrective Maintenance

This type of maintenance is reactive — it’s triggered when something goes wrong. If users experience a bug in the payroll module or encounter system errors when generating reports, corrective maintenance involves troubleshooting the issue, identifying the root cause, and deploying fixes.

Corrective actions can include repairing scripts, restoring data integrity, or rolling back recent changes. The goal is to restore system functionality as quickly as possible while minimizing business disruption.

2. Preventive Maintenance

Preventive maintenance is proactive. It focuses on identifying and resolving issues before they turn into serious problems. This includes routine health checks, patching, database optimization, and testing critical integrations.

The objective is to reduce the likelihood of unexpected outages, improve system performance, and extend the ERP system’s lifespan.

3. Adaptive Maintenance

Business needs are constantly evolving. Adaptive maintenance ensures that your ERP system keeps pace. Whether you're introducing a new business process, adding a department, or complying with new tax regulations, adaptive maintenance involves reconfiguring workflows, adding new modules, or integrating new tools.

This keeps the system relevant, agile, and aligned with current operational requirements.

4. Perfective Maintenance

Perfective maintenance is all about improvement. It focuses on enhancing usability, refining performance, or introducing new capabilities that make the system more intuitive and powerful for users.

Examples include redesigning dashboards based on user feedback, improving approval workflows, or adding mobile access for project managers.

Top ERP Maintenance Challenges

Even with a clear plan in place, maintaining an ERP system can pose challenges. The more complex the business, the more likely it is to encounter friction points in its maintenance routines. Here are some of the most common barriers companies face:

1. Limited Internal Resources

Many companies struggle with having too few IT staff to cover both day-to-day system support and long-term maintenance. This often leads to reactive fire-fighting instead of proactive upkeep.

2. Over-customization

Custom features often serve important business needs, but they can complicate future maintenance. The more customized your ERP is, the harder it becomes to apply vendor updates, test patches, or scale features. Without proper documentation, even small updates can cause critical failures.

3. Inconsistent or Inaccurate Data

ERP systems rely on accurate, real-time data to function effectively. But when departments use different formats or workflows, discrepancies emerge, leading to errors in financial reporting, procurement, or resource planning.

4. Resistance to Change

When ERP updates change how employees do their jobs, even if it’s for the better — pushback is common. Without clear communication and hands-on training, users may ignore new features or revert to old habits, which undermines the value of ERP maintenance.

5. Difficulty Maintaining Third-party Integrations

ERP systems rarely operate in isolation. They must sync with CRM tools, HR platforms, bank feeds, and compliance systems. A change in any one of those systems can cause cascading issues across the ERP environment, especially if integration monitoring isn’t built into the maintenance process.

While these challenges may seem daunting, they’re not insurmountable. With the right strategy in place, businesses can overcome these roadblocks and ensure their ERP systems remain efficient, reliable, and fully aligned with business objectives.

9 ERP Maintenance Best Practices

While ERP maintenance can feel like a complex task, following a clear set of best practices helps companies stay organized, responsive, and efficient. These aren’t just technical checklists, they’re strategies that ensure your ERP evolves alongside your business.

Let’s take a closer look at the nine most effective ERP maintenance practices and how they support long-term operational excellence.

1. Regular System Updates

Staying up to date with ERP vendor patches and version releases is one of the most critical parts of maintenance. These updates don’t just fix bugs — they often include regulatory changes, new features, and performance enhancements. The key is to establish a controlled update process, where changes are tested in a sandbox environment before going live.

Companies with on-premise ERP systems should maintain a quarterly update schedule, while cloud ERP users must still monitor vendor releases to ensure changes don’t disrupt business-critical processes.

Only 31% of ERP projects are delivered on time and within budget.[?]

2. Data Backup & Recovery

Backups are your last line of defense against data loss. This includes daily incremental backups, encrypted off-site storage, and regular recovery drills. It’s also vital to document who is responsible for restoring data and how long recovery should take.

Routine testing of backup integrity is just as important as performing the backup itself. Without proper DR (disaster recovery) protocols, companies risk losing not just financial data, but critical operational history.

3. User Training & Support

Many ERP challenges stem not from the system, but from inconsistent user understanding. Training should not be a one-time event at go-live. Instead, it should be an ongoing initiative that includes onboarding for new hires, refresher courses for core users, and update-specific training for new features.

Provide easily accessible help resources, keep documentation updated, and offer channels where users can request assistance. Well-trained users are more confident, productive, and less likely to revert to manual workarounds.

4. Performance Monitoring & Optimization

Use real-time analytics to track response times, error rates, and transaction loads. These insights help you spot inefficiencies and address them before they become bottlenecks. Optimization efforts might include reindexing databases, revising slow reports, or reviewing high-volume processes.

You should also plan for scalability. As your user base or data volume grows, adjust your server capacity or cloud configurations accordingly to maintain speed and stability.

5. Security & Access Control Management

Security must be reviewed regularly, not just in response to threats. This includes auditing user roles, reviewing admin privileges, enforcing multi-factor authentication, and closing unused ports or legacy integrations.

Stay updated on regional data protection regulations (such as GDPR or the UAE’s Personal Data Protection Law), and ensure your ERP aligns with compliance mandates. Regular vulnerability assessments and penetration testing can prevent costly breaches.

6. Customization & Scalability Maintenance

Every ERP system contains some level of customization, but too many modifications without documentation or version control can slow updates and increase error rates. Revisit all custom workflows annually to assess whether they still serve a purpose or can be replaced by native ERP functionality.

Scalability is another key factor. As the business grows, will your ERP be able to handle new departments, data sets, or regulatory requirements without overhauling your infrastructure?

7. Professional ERP Support

Even well-staffed IT teams can benefit from outside expertise. Work with ERP vendors or certified partners to conduct annual system health checks. These professionals can help identify overlooked risks, optimize configurations, and support major upgrades.

Establish SLAs (Service Level Agreements) that define response times, issue severity levels, and escalation paths. This ensures that your business isn’t left waiting during a critical system issue.

8. Integration Audits

Your ERP rarely works alone. It connects with payroll systems, banking platforms, inventory tools, and CRMs. These integrations must be audited regularly to ensure data flows correctly, especially after updates to third-party software.

Common issues include API changes, authentication errors, and format mismatches. Flagging these early prevents reporting discrepancies and manual rework.

9. Feedback Loops & Continuous Improvement

ERP maintenance should not be confined to the IT department. Establish ongoing communication with end users through surveys, review meetings, or support logs to capture how the system performs in daily workflows.

Use this feedback to drive feature prioritization, improve training materials, and refine internal processes. Treat the ERP not as a static tool, but as a living system that adapts to your team’s evolving needs.

Together, these best practices help businesses get more from their ERP system every quarter, not just during implementation. They reduce risk, improve performance, and lay the foundation for growth.

ERP Maintenance Plan That Meets Your Needs (About FirstBit ERP)

Putting a sound ERP maintenance strategy into action requires more than just internal effort — it also depends on having the right software partner. FirstBit ERP offers a practical, industry-aligned approach to ERP maintenance, particularly for companies operating in construction, contracting, and project-driven environments.

Unlike generic systems that rely heavily on third-party integrations, FirstBit ERP provides a unified platform where core functions like project costing, procurement, HR, payroll, and accounting are built to work together out of the box. This reduces the complexity of maintenance and minimizes the risk of broken workflows during system updates.

-

Automated Updates and Local Compliance. FirstBit ERP ensures regulatory compliance through timely updates, including changes in VAT, e-invoicing, and labor laws in the UAE and Saudi Arabia. These updates are managed centrally and tested to ensure stability, meaning clients don’t have to chase patches or worry about software compatibility during each compliance cycle./div>

-

Built-in Tools for Data Integrity and Monitoring. To support preventive maintenance, FirstBit provides real-time dashboards, audit logs, and access control features that help companies detect anomalies early, whether it's a user access issue or a discrepancy in project budget tracking. These built-in tools reduce reliance on external monitoring solutions and keep maintenance efforts efficient and centralized.

-

Support That Understands Construction. FirstBit’s support team is regionally based and trained in construction workflows. This makes issue resolution faster and more effective, as clients don’t need to explain basic industry processes like retention, subcontractor billing, or multi-project inventory management.

-

Ongoing System Optimization. FirstBit clients benefit from periodic system health checks, role-based user training, and tailored advice on how to improve internal processes using the ERP. These services help ensure the ERP evolves as the business scales, avoiding the stagnation or misalignment that leads many systems to underperform over time. By combining industry-specific workflows with built-in monitoring tools, local compliance updates, and expert support teams, FirstBit ERP helps businesses in the GCC maintain a resilient, future-ready system. It eliminates many of the common barriers to ERP upkeep — from scattered integrations to regulatory gaps and provides a stable foundation that grows with your operations.

Conclusion

ERP maintenance is not an afterthought, it’s a core business discipline. As organizations grow, diversify operations, and navigate evolving regulatory landscapes, the ERP system must remain not only functional but adaptable and secure. This is only possible with a structured maintenance strategy that combines technology, processes, and people.

When done right, ERP maintenance reduces downtime, protects sensitive data, and ensures every department operates with accurate, real-time insights. It’s what turns ERP from a static tool into a dynamic asset, one that continues to support strategic decisions, operational efficiency, and financial control.

Whether you’re running a mid-sized construction firm or managing a portfolio of complex projects across borders, the difference between an ERP system that just works and one that drives business value is how well it’s maintained.

Start where you are, build internal alignment, and lean on partners who understand your operational reality. Because in ERP, longevity and impact come from care, not just configuration.

F.A.Q.

What is ERP maintenance, and why is it important for business efficiency?

How often should an ERP system be maintained for optimal performance?

What are the common challenges businesses face with ERP maintenance?

What are the key benefits of following ERP maintenance best practices?

What are the best tools or software for ERP system monitoring and maintenance?

What is the cost of neglecting regular ERP maintenance?

Umme Aimon Shabbir

Editor at First Bit

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.