As your construction projects grow, managing purchase orders becomes increasingly challenging. You're likely struggling with missed delivery deadlines, lost supplier commitments, or hours spent processing purchase documents manually — problems that directly impact your project timelines and costs.

You've likely faced these common challenges: suppliers claiming they never received orders, materials arriving late, or purchase approvals stuck in lengthy email chains. This manual tracking chaos doesn't just delay your projects — it strains supplier relationships and costs you money through missed payment deadlines and lost bulk purchase opportunities.

In this article, you'll learn how to take control of your construction purchase orders. We'll show you how to choose the right purchase order types for different situations, set up approval workflows that scale across projects, and create documentation that protects your interests. You'll discover proven steps to transform manual tracking into a streamlined system that saves time and prevents costly errors.

Types of Construction Purchase Orders

Construction projects use four main types of purchase orders, each serving different needs:

1. Standard Purchase Orders

These are the most common purchase orders used for one-time purchases when you need specific items or services.

They work like a detailed shopping list, clearly stating what you're buying (exact items and quantity), how much it costs, or when and where it should be delivered.

For instance, a construction company needs 5,000 ceramic tiles for a luxury hotel's lobby renovation project. They issue a standard purchase order to ABC Tiles, specifying the exact model number, price of $45 per square meter, and delivery required within two weeks to the construction site in Downtown Dubai. This one-time order includes all delivery instructions, payment terms, and quality specifications.

2. Planned Purchase Orders

These are advance orders for materials you know you'll need in the future.

This type of purchase order helps plan budgets better, give suppliers early notice, and ensure materials arrive when needed.

For instance, a construction company building a 20-story apartment complex requires 100 cubic meters of concrete each month for six months. The company issues a planned purchase order to its concrete supplier, detailing the delivery of 100 cubic meters on the first Monday of each month, with specific mix requirements and delivery times to match their foundation and floor-casting schedule.

3. Blanket Purchase Orders

These work like an ongoing agreement with a supplier for regular purchases over a long period (usually a year).

They're useful for items you need often, saving time on paperwork and getting better prices through bulk agreements.

For instance, a construction company managing multiple projects across Dubai sets up a blanket purchase order with Emirates Equipment Rentals for a year's worth of machinery access. Under this agreement, they can rent excavators, cranes, and bulldozers at pre-negotiated rates whenever needed, simply by making a phone call without creating new purchase orders each time.

4. Contract Purchase Orders

These are formal agreements that combine a contract and a purchase order into one document.

They're used for complex or high-value purchases, long-term service agreements, and projects requiring specific legal terms.

For instance, a construction company needs 5,000 ceramic tiles for a luxury hotel's lobby renovation project. They issue a standard purchase order to ABC Tiles, specifying the exact model number, price of $45 per square meter, and delivery required within two weeks to the construction site in Downtown Dubai. This one-time order includes all delivery instructions, payment terms, and quality specifications.

These four types of purchase orders help construction companies buy what they need in the best way possible. Each type serves a different purpose - from buying something just once to planning ahead for future materials to setting up regular supply arrangements or making detailed legal agreements.

The most important thing is to pick the right type by thinking about two simple questions: "How often do we need these materials?" and "How detailed does the agreement need to be?"

Reduce costs and avoid shortages

Optimize procurement with FirstBit

Request a demo

Why Purchase Order Management Matters in Construction

Many construction managers rely on informal purchasing processes, tracking orders through emails and spreadsheets. However, this approach often leads to costly mistakes and missed opportunities. Let's explore why proper purchase order management isn't just extra paperwork but a crucial tool for protecting your bottom line.

1. Automates Your Procurement

Purchase order management makes

procurement easier by putting all purchasing steps into one automated system. It gets rid of paperwork and mistakes while making the whole process faster through standardized digital workflows.

You can easily see your orders, supplier details, and create reports, while keeping better control of your inventory. This leads to quicker orders, lower costs, and better relationships with suppliers, making the entire procurement process more efficient and cost-effective.

2. Tracks Every Dirham

Purchase order management helps companies keep track of their spending and stay within their budget by creating a clear record of every purchase. It's like having a smart checkbook that shows exactly what was bought, at what price, and by whom. This system warns managers before money is spent, lets them compare prices between suppliers, and spots any unusual spending right away.

By having all purchase information in one place, companies can easily see where their money is going, avoid surprise costs, and make better decisions about future spending. This helps save money by preventing overbuying, catching pricing errors, and making sure everyone sticks to approved spending limits.

3. Builds Stronger Supplier Partnerships

By implementing effective purchase order management, organizations can strengthen supplier relationships through a simplified ordering process. This streamlined system enables suppliers to clearly understand both the specific requirements and delivery timelines, leading to more efficient collaboration.

4. Protects Your Interests

When disputes arise, this detailed audit trail becomes your strongest defense, protecting your company from costly misunderstandings and potential legal issues.

Key Steps in Successful Purchase Order Management for Construction

If you've ever struggled with delayed deliveries or lost track of construction materials, you know the importance of a coherent strategy that will help you take control of your purchasing process. These steps will help keep your projects running smoothly.

1. Identification of Requirements

The PO processing in construction starts when someone on the project identifies that materials or services are needed.

This typically happens in several common situations:

-

When checking the project timeline and seeing upcoming work that requires specific materials

-

When site supervisors report that inventory of crucial items like cement, steel, or lumber is running low

-

When daily site inspections reveal unexpected material needs

-

When unforeseen situations arise, such as weather damage requiring additional supplies

Set clear reorder points - for example, trigger new orders when concrete supply drops to 30% or when lumber stock falls below a two-week supply. Create a daily checklist for site supervisors to report any unexpected material needs, weather-related issues, or potential shortages.

To ensure timely material arrival, establish standard lead times for common materials (for instance, allow 5 days for local suppliers and 2 weeks for specialty items). Build a safety buffer by ordering materials to arrive at least 3-5 days before their scheduled use.

2. Creating a Purchase Requisition

A purchase requisition is the essential first step in the procurement process, acting as a formal internal request document for goods or services. To create an effective purchase requisition, focus on these key components:

-

Start with a clear description of the items needed. Specify exact materials, brand names, grades, and technical requirements. Be precise about dimensions, quality standards, and any specific characteristics that will ensure you receive exactly what the project needs.

-

Include precise quantity details in appropriate units of measurement (pieces, tons, cubic yards). Make it clear whether partial deliveries are acceptable and specify any packaging requirements. This precision helps prevent costly ordering mistakes and inventory issues.

-

State your delivery requirements clearly. Include both the target date and any specific timing restrictions. Consider lead times and link the delivery to project milestones to ensure materials arrive when needed. Remember that realistic delivery dates are crucial for project planning.

-

Include accurate project identifiers and cost codes. Every requisition must have the correct project name, number, and relevant accounting codes. This ensures proper cost tracking and makes the approval process smoother. Add your contact details and any special delivery instructions to complete the request.

3. Vendor Selection and Bid Comparison

The vendor selection process starts with gathering quotes from multiple suppliers. Contact at least three different suppliers and provide them with clear specifications, quantities, and delivery dates. Set a firm deadline of 3-5 days for quote submissions and keep all communications documented through email or your procurement system.

When

comparing bids, create a simple comparison of total costs, including base prices, delivery fees, payment terms, and any available discounts. This comparison helps you understand the full cost picture beyond just the basic price quotes.

During evaluation, look at each supplier's track record for deliveries, material quality, and how quickly they respond to issues. Consider practical factors like their location and ability to handle emergency orders. A supplier's financial stability is also important to ensure they can support your project consistently.

After selecting a supplier, document the reasons for your choice and maintain good communication with them. Building strong relationships with suppliers often leads to better service and support when you need it most.

Remember that while price matters, reliability and consistent service are equally important in choosing the right supplier for your construction needs.

4. Purchase Order Creation

Creating an effective purchase order is a step that turns your material request into a binding agreement. Every purchase order needs a unique PO number and current date for easy tracking and reference.

The vendor section in the document requires complete accuracy. Include the supplier's legal business name, address, and contact details. Double-check these details, especially for new vendors, as mistakes here can cause delivery and payment issues.

For the delivery information, specify both the exact site address and any special access instructions. Include a contact person's name and phone number to ensure smooth delivery.

The heart of your PO is the detailed list of what you're ordering. Each item should have a clear description matching the supplier's quote, precise quantities, and agreed prices. Be specific - instead of just writing "lumber," specify "2x4 pressure-treated pine lumber, 16-foot lengths." Include both unit prices and total amounts to avoid confusion.

Finally, clearly state your payment terms and any special conditions. This might include details like "Net 30 days" or "2% discount if paid within 10 days." Add any crucial notes about delivery timing, quality requirements, or required certifications.

Remember — what's not written in the PO might not be honored, so include all important details while keeping it clear and concise.

5. Verification and Approval

The first review happens at the project level, where project managers or supervisors must check each PO within 24 hours of creation.

During this review, they need to verify four key elements:

-

The quantities match the project's actual needs

-

The prices align with the project budget

-

The delivery dates work with the construction schedule

-

All specifications are correct

Project managers should maintain a daily schedule for PO reviews, perhaps setting aside a specific time each morning to handle these approvals.

After project-level approval, the purchasing department takes over. They must verify that the vendor is approved and in good standing, confirm that prices match established agreements, check that payment terms are correct, and ensure all required documentation is attached. The purchasing team should use a standardized checklist to maintain consistency and speed up the process.

6. Order Confirmation

When you send a purchase order to a vendor in the construction industry, getting proper confirmation is crucial for your project timeline. A good order confirmation process starts immediately after sending the PO - you should expect to receive an acknowledgment within 24 hours. If you don't receive it, make a follow-up call or send an email to ensure your PO wasn't missed or lost in spam folders.

The vendor's confirmation should address several key points. They need to verify that they can supply the exact materials you've ordered in the specified quantities. They must also confirm that they can meet your delivery date and agree to your stated price and payment terms.

Pay special attention to their response about delivery dates - this is particularly important in the UAE market, where import times and customs clearance can affect timelines.

Don't just file away the confirmation when you receive it. Check it carefully against your original PO for any discrepancies.

Look specifically for differences in:

If you notice any differences, even small ones, address them immediately. Send a clear email highlighting the discrepancies and request corrected confirmation. Keep all these communications documented - in UAE construction projects, having a clear paper trail is essential for both legal and audit purposes.

7. Tracking and Accounting

Set up a straightforward system to monitor all purchase orders from start to finish. Review open POs each morning using a simple color code: Green (on-track), Yellow (needs attention), and Red (urgent/delayed).

For UAE projects, pay special attention to import status and customs clearance for international shipments. Your tracking system should clearly show expected delivery dates, current status, and any potential issues.

When materials arrive, follow a quick but thorough verification process. Check quantities against the delivery note, verify quality meets specifications, and document any damage. In UAE's climate, take photos of sensitive materials upon delivery. Only sign delivery notes after proper verification - this simple step prevents many future problems.

Maintain organized digital files linking each PO with its delivery notes and invoices.

For UAE compliance, keep records of:

Set up payment reminders 5 days before due dates, typically working with 30-60-day terms common in UAE construction. Before releasing any payment, quickly verify that all documentation matches and required approvals are in place. Complete a monthly reconciliation to ensure all records align with actual site receipts and payments.

8. Receiving and Inspection

When a delivery arrives, have your site supervisor or storekeeper check essential things before the delivery truck leaves.

Three essential things:

-

Match quantities with your PO numbers

-

Inspect materials for visible damage

-

Verify that specifications match what you ordered

Keep the delivery driver present during this initial check - it's easier to resolve issues immediately than later.

If you spot any issues, document them right away:

-

Take clear photos of damaged items

-

Note exact quantities that are missing or extra

-

Write specific details on the delivery receipt

-

Have the delivery driver sign your notes

Send this information to your supplier within the same day, including photos. Quick reporting means quicker solutions.

Once you've completed the checks, update your systems immediately:

-

Enter received quantities in your inventory system

-

Attach delivery notes to the original PO

-

Update project stock levels

-

Mark the PO as fully or partially received

-

File documentation in your project folder

End each day with all deliveries properly recorded — this

keeps your inventory accurate and helps prevent payment issues later. Digital solutions like FirstBit ERP can help your construction purchasing from order to delivery. Store, track, and monitor all purchase orders in one digital workspace, eliminating hours of manual paperwork. Watch your deliveries in real time while the system automatically handles the routine tasks that are used to slow you down.

Get top-quality materials at the best prices for your construction project

Request a demo

Best Practices for Purchase Order Management

While every construction project is unique, implementing these fundamental practices can transform your purchase order management from a potential bottleneck into a strategic advantage.

-

Conduct thorough market research. Stay informed about current material prices and supplier capabilities to make cost-effective purchasing decisions. Regular market analysis helps identify reliable suppliers and negotiate better terms while avoiding supply chain disruptions.

-

Clearly define project scope. Document exact material specifications and quantities needed before initiating any purchase orders. Clear scope definition prevents ordering errors and reduces the need for costly change orders later in the project.

-

Emphasize risk management. Include contingency plans for critical materials and maintain relationships with multiple suppliers for essential items. This approach helps mitigate supply chain risks and ensures project continuity even when primary suppliers face challenges.

-

Standardize your purchasing order format and numbering system. Use consistent PO formats and implement a logical numbering system that allows easy tracking and reference. A standardized system reduces confusion and makes it easier to audit and track orders across multiple projects.

-

Implement a clear approval process with defined thresholds. Establish specific approval levels based on purchase amounts and maintain a documented approval workflow. Clear authority limits to speed up the approval process while maintaining proper control over expenditures.

-

Regularly review and update your approved vendor list. Evaluate supplier performance quarterly and maintain an updated list of reliable vendors. Regular reviews help maintain quality standards and ensure competitive pricing while eliminating underperforming suppliers.

-

Train your staff on proper PO procedures. Provide regular training sessions on PO procedures and updates to procurement policies. Well-trained staff make fewer errors and process orders more efficiently, reducing delays and administrative costs.

-

Use digital solutions to automate and track purchase orders. Implement construction-specific procurement software to streamline the PO process and provide real-time tracking. Digital solutions reduce manual errors, speed up approvals, and provide better visibility into procurement status and spending patterns.

Modern ERP systems designed for construction integrate all these best practices into a single platform, making implementation straightforward and sustainable.

For example, FirstBit ERP system automates the entire PO lifecycle through features like:

-

Automatic PO numbering prevents duplicate orders

-

Built-in approval routing sends notifications to the right managers based on pre-set spending limits

-

Real-time dashboards show all open orders, pending approvals, and delivery statuses across projects

FirstBit ERP flags

budget overruns before they happen, while digital forms with required fields ensure complete information every time. You can instantly see their material status, accountants can match invoices to POs with a single click, and site teams can track deliveries through mobile apps.

All documents, from quotes to delivery notes, are stored digitally and linked to relevant POs, making audit trails and vendor performance tracking automatic rather than manual tasks.

Align every purchase with project goals

Track supplier performance and control costs

Request a demo

How FirstBit ERP Can Improve Purchase Order Management

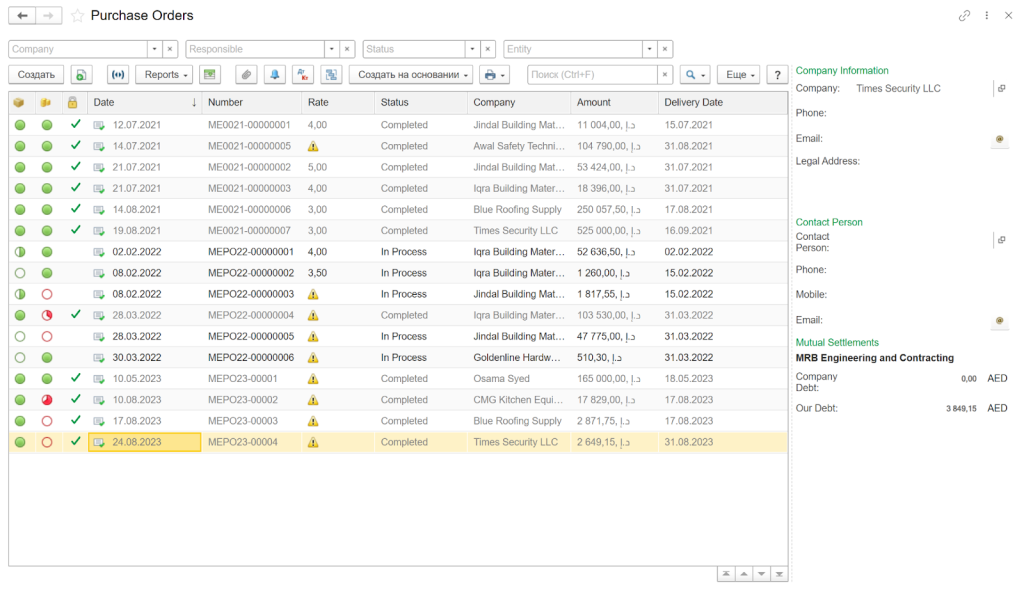

Here's a detailed breakdown of how FirstBit ERP improves Purchase Order Management:

Manages the complete lifecycle of purchase orders from creation to closure in one unified system. Users can track order status in real-time, set up automated vendor communications, and monitor delivery schedules across multiple projects simultaneously.

Purchase Orders in FirstBit ERP

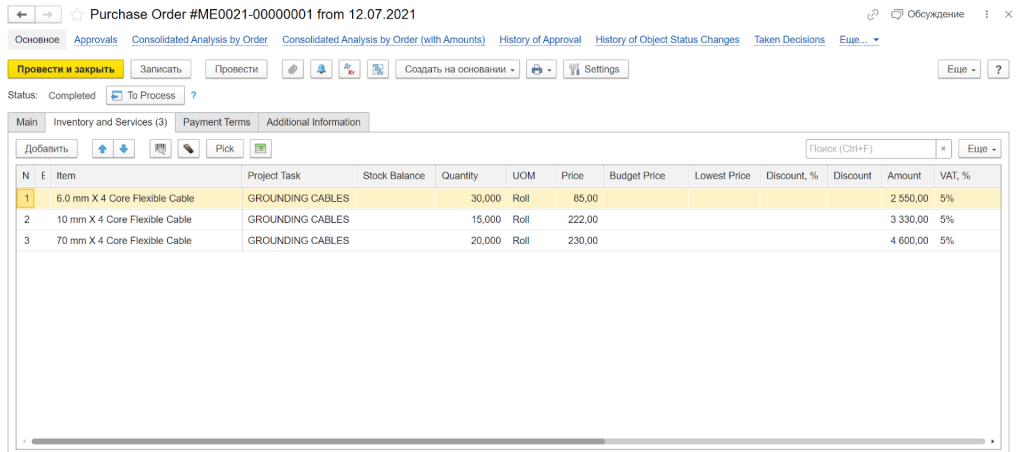

Calculates discounts automatically and maintains accurate records of vendor payments, helping prevent overpayments and missed payment deadlines.

Purchase Order Details in FirstBit ERP

This integrated approach ensures that construction companies can manage their purchase orders efficiently while maintaining full compliance with UAE tax regulations and industry best practices.