Every successful construction project starts long before the first brick is laid. Decisions made during the

planning and procurement stages often determine whether a project stays on budget, finishes on time, or spirals into delays and disputes. A major part of this process is how owners and contractors communicate with potential suppliers and partners.

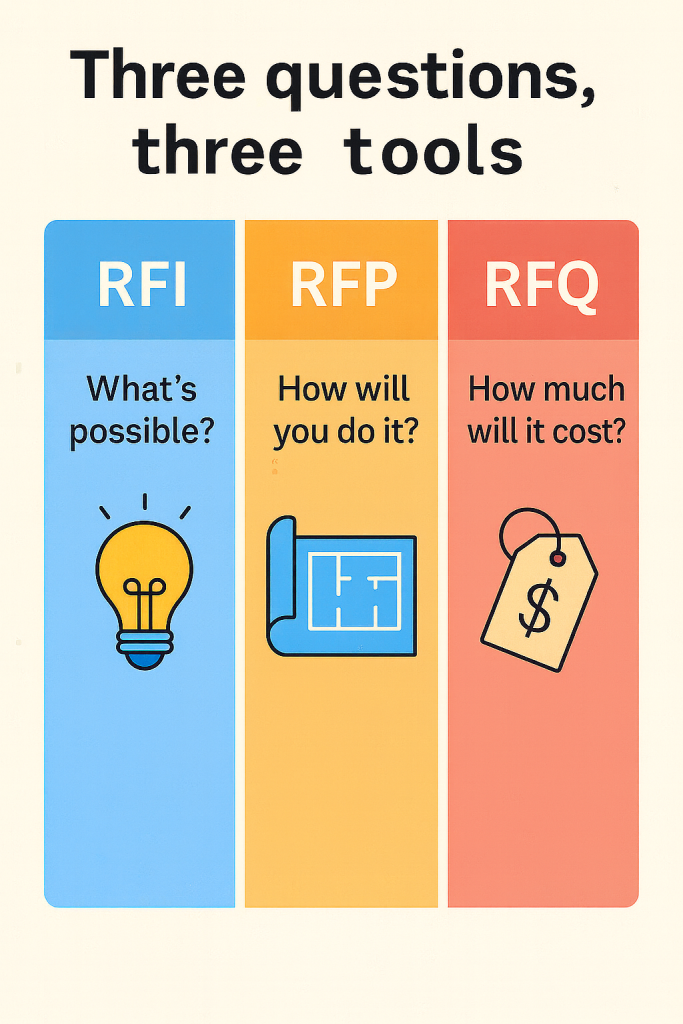

This is where RFIs, RFPs, and RFQs come into play. These structured requests cut through uncertainty by standardizing how information, proposals, and pricing are gathered. Each serves a distinct purpose: an RFI in construction uncovers possibilities, an RFP evaluates solutions, and an RFQ secures costs. Together, they form the backbone of transparent and competitive procurement.

Yet many firms still use them interchangeably or worse, skip them altogether, leading to vague bids, mismatched expectations, and financial risk. By clearly understanding the differences between RFP vs RFQ, vs RFI, construction professionals can make smarter choices, negotiate with confidence, and set projects up for success from day one.

What Is an RFx in Construction?

At a glance, “RFx” might just look like a buzzword, but it’s really a powerful toolset that gives structure to how construction teams communicate with vendors. “RFx” stands for Request for X, where the “X” gets replaced with information you need:

-

RFI (Request for Information). A low-stakes, non-binding ask to clarify unknowns. Think: “Is this finish acceptable? What are your lead times?” It helps you confirm what you don’t know before making decisions.

-

RFP (Request for Proposal). This is for depth. You’re asking for not just numbers, but the how. Methods, schedules, credentials, and value-based solutions are especially useful when the approach matters as much as the price.

-

RFQ (Request for Quotation). When you know exactly what you want, materials, equipment, labor, and just need to lock in the price with minimal ambiguity.

These aren’t just different documents; you use them at different times in the project lifecycle. Start with an RFI when uncertainty is high, bring in RFPs when comparing approaches in the design or build phase, and finish with RFQs when price-tie decisions are ready to be made.

RFI Meaning in Construction

In construction, a

Request for Information (RFI) is a formal method to clear up uncertainties before decisions are locked in. It’s not a bid or a commitment. It’s a structured way to ask targeted questions, document answers, and keep design and scope aligned so work can proceed without guesswork.

Rework is costly: the Construction Industry Institute (CII) reports that rework typically equals 2%–20% of a project’s contract value[?].

RFI in construction is used to clarify drawings and specifications, confirm code interpretations, and address site conditions that weren’t apparent during design. They’re also helpful when exploring unfamiliar systems or materials, so teams can understand options and constraints before moving to pricing or proposals.

RFIs are non-binding for both sides. Vendors can share information without committing to a price, and the project team can refine requirements without awarding work. A good RFI cites the exact drawing/spec clause, states the question clearly, notes any schedule impact, and sets a reasonable “answer-by” date. Typical prompts include: available technical options, lead times and logistics, performance data, compatibility with adjacent trades, and any required certifications or testing.

Handled this way, RFIs reduce ambiguity early and make subsequent RFQ and RFP steps faster and more accurate.

Choose the best suppliers

Compare quotes side‑by‑side, evaluate cost and quality with FirstBit ERP

Request a demo

RFI in Construction: When To Use and What To Include

A Request for Information (RFI) is one of the earliest tools in the procurement cycle, helping project owners and contractors clarify scope, explore options, and avoid costly misunderstandings later. Unlike an RFQ or RFP, the RFI doesn’t seek firm pricing or detailed proposals; its role is to open a structured dialogue and collect insight that guides the next steps. When issued thoughtfully, an RFI can save weeks of back-and-forth during bidding and prevent misalignment that often leads to rework or disputes.

When to Use an RFI in Construction

RFIs are most useful when the project scope or requirements are still taking shape. They give teams the chance to gather intelligence before committing to design decisions or issuing quotes. Common situations include:

-

Early planning stages. When a project is still in conceptual design, RFIs help identify the range of options available. For instance, a project owner evaluating energy systems may use an RFI to compare solar panel technologies before defining specifications.

-

Exploring unfamiliar markets or technologies. Contractors entering a new region or adopting new construction methods may use RFIs to learn about local suppliers, compliance requirements, or innovative products.

-

Clarifying unclear requirements. If the design documents leave questions unanswered, such as material performance standards or site preparation details, an RFI provides a formal way to seek clarification without delaying progress.

What to Include in an RFI in Construction

An RFI should provide just enough structure for vendors to respond clearly, while still leaving room for them to share insights beyond what the buyer may have anticipated. Typical inclusions are:

-

Background of the buyer and project context. A short description of the project helps suppliers understand the bigger picture. For instance, stating that the project is a hospital expansion signals the need for strict compliance with healthcare standards.

-

Project goals. Broad objectives such as “improving energy efficiency” or “reducing long-term maintenance costs” guide suppliers in tailoring their responses.

-

High-level questions. Open-ended prompts like “What innovative methods do you use to reduce on-site installation time?” or “How do your products support sustainability certifications?” encourage suppliers to share differentiators.

-

Timeline expectations. Giving vendors an idea of when the project is scheduled to start ensures that their recommendations reflect realistic availability and lead times.

-

Preferred response format. Even though the RFI is less formal than an RFQ or RFP, suggesting a structure (e.g., company profile, product options, case studies) makes it easier to compare submissions later.

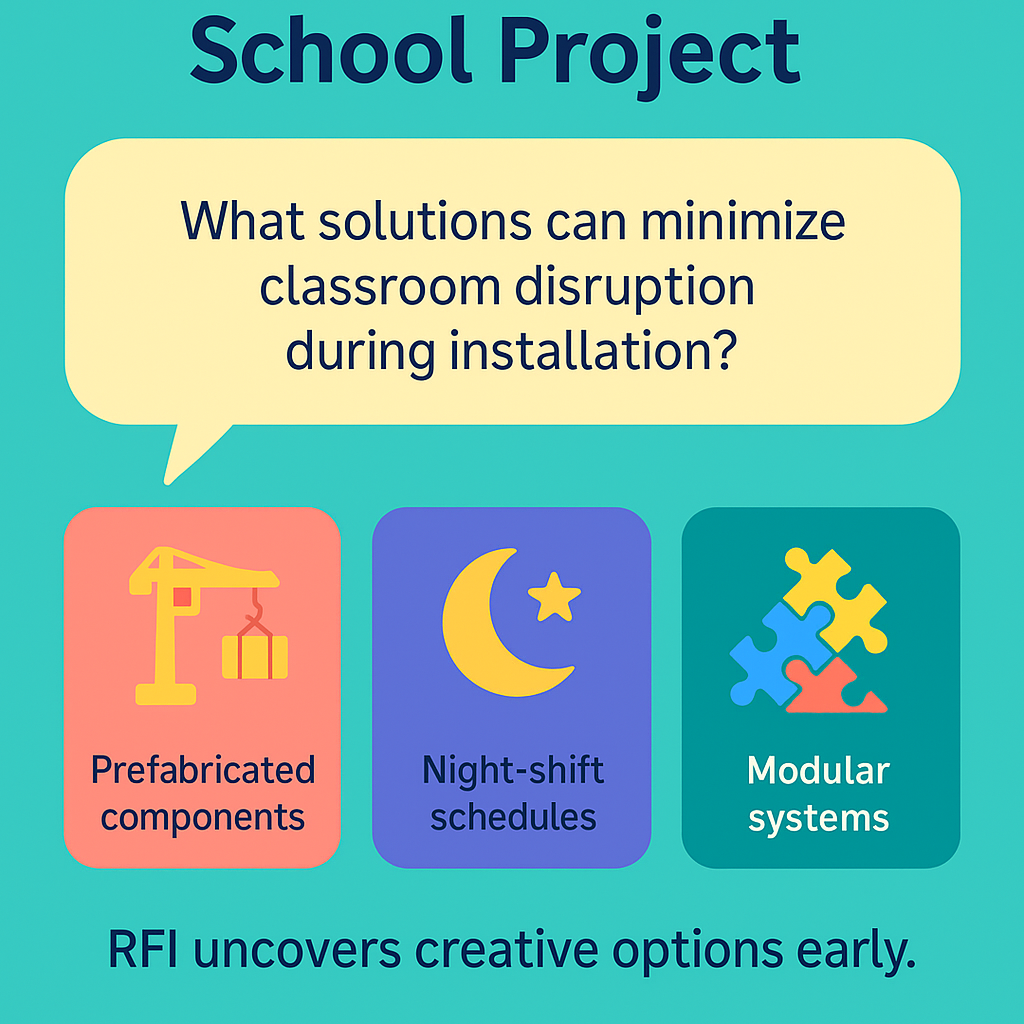

For example, suppose a contractor is planning to modernize a school building. In that case, they might include a high-level question like:

“What solutions can you provide that minimize classroom disruption during installation?”.

Some suppliers might highlight prefabricated components, while others suggest night-shift schedules or modular systems. This type of open-ended inquiry helps uncover practical approaches that the contractor may not have considered initially.

Example of how RFIs uncover practical solutions in construction projects

Example

Consider a contractor tasked with designing a mid-rise office building that must achieve a specific sustainability certification, such as LEED Gold. One of the critical decisions is selecting the right HVAC system, a choice that affects not only upfront costs but also long-term operating efficiency and compliance with environmental standards.

At this early stage, the contractor doesn’t yet know which technology or vendor will be the best fit. Instead of moving straight to pricing, they issue RFIs to multiple suppliers of energy-efficient HVAC systems. Each supplier is asked to provide information about:

-

The energy performance of their systems, including seasonal efficiency ratings

-

Compatibility with smart building management platforms

-

Expected maintenance cycles and associated costs

-

Estimated lifespan and warranty terms

-

Compliance with green building standards such as ASHRAE or LEED prerequisites

When the responses come back, the contractor gains a clear picture of the available technologies and how each supplier positions their solution. One vendor may highlight advanced IoT-based controls, while another emphasizes lower upfront installation costs but higher long-term maintenance.

By comparing this input side by side, the contractor can narrow down the field to suppliers that not only meet performance requirements but also align with project goals and client expectations. This process ensures that the next step, whether issuing an RFQ for pricing or an RFP for a comprehensive proposal, is grounded in accurate and relevant information rather than guesswork.

RFP Meaning in Construction

A

Request for Proposal (RFP) is more than just a request for cost estimates; it is a structured invitation for vendors to present their detailed solutions to a project. RFP in construction is particularly useful for complex projects where owners need to assess not only price but also methodology, experience, and alignment with technical requirements.

An RFP typically includes:

-

A detailed project overview

-

A clear scope or Statement of Work (SOW)

-

Technical requirements, including regulatory and sustainability criteria

-

Proposal format guidance

-

Evaluation criteria used to compare submissions

-

Contract terms, including delivery milestones and performance expectations

Government agencies and other organizations issue most RFPs in the public sector. They are generally required to open up competition among private companies and remove bias from the process[?].

This highlights why RFPs carry weight in the industry; they are designed to ensure transparency, fairness, and competitive bidding, which are critical in large-scale or publicly funded construction projects.

Get top-quality materials at the best prices for your construction project

Request a demo

RFP in Construction: When To Use and What To Include

An RFP (Request for Proposal) is the tool of choice when projects are too complex to be decided on price alone. Instead of just asking “how much will it cost?”, an RFP pushes vendors to explain how they intend to deliver the project, what methods they’ll use, and how they’ll manage risks. In construction, where safety, compliance, and timelines are non-negotiable, RFPs help owners evaluate vendors holistically, looking at capability, quality, and value in addition to cost.

When to Use an RFP in Construction

An RFP is most effective in situations where the scope is defined, but the execution could follow different approaches. Common scenarios include:

-

Large or technically demanding projects where design, safety, and compliance all have to be carefully managed.

-

Projects with multiple delivery approaches, such as modular vs. on-site construction or using alternative materials.

-

Long-term partnerships, such as facility management contracts or multi-phase infrastructure builds.

-

Projects with multiple stakeholders, where transparency in vendor evaluation helps secure buy-in and minimize disputes.

-

Cases requiring innovation, for example, energy-efficient systems or sustainable building practices, where contractors need to propose creative solutions.

In Deloitte’s 2025 Chief Procurement Officer Survey, 61% of procurement leaders said they are prioritizing enhanced supplier information sharing and collaboration to drive value and reduce risk[?].

This reflects why RFPs are a critical part of modern construction procurement. By focusing on structured proposals, they allow project owners to weigh not just prices but also the methodologies and safeguards that vendors bring to the table.

What to Include in an RFP in Construction

For an RFP to be effective, it must strike the right balance between being detailed enough to guide vendors and structured enough to ensure consistent responses. A well-prepared RFP usually contains:

-

Project overview and objectives. A clear description of the project’s purpose, location, and expected outcomes. This ensures all bidders understand the broader goals, not just the technical specs.

-

Statement of Work (SOW). A breakdown of tasks, responsibilities, and deliverables. This clarifies what the contractor is expected to provide and helps avoid scope disputes later.

-

Technical specifications and compliance requirements. Industry standards, certifications, or specific codes that must be followed. For example, seismic safety in certain regions or LEED certification for sustainable buildings.

-

Timeline and milestones. A realistic schedule with key delivery points, such as foundation completion, structural handover, or installation of critical systems. This helps vendors align their workforce and resources.

-

Proposal format and submission guidelines. Standardized formats (tables, breakdowns, etc.) make it easier to compare bids. For instance, requiring separate line items for labor, materials, and contingency costs.

-

Evaluation criteria. Transparent benchmarks for how the proposals will be judged — experience, technical approach, safety record, or innovation.

-

Commercial and legal terms. Contract length, payment terms, penalties for delays, and warranty conditions. Including these upfront reduces negotiation bottlenecks later.

Tip: The more structured the RFP, the easier it is to compare submissions on equal grounds. This reduces ambiguity and ensures decisions are made on facts rather than assumptions.

Example

Consider a project owner who plans to build a new hospital facility. The project is highly complex, involving specialized requirements such as:

-

Healthcare-specific systems. HVAC with HEPA filtration, negative pressure isolation rooms, and medical gas pipelines.

-

Technology integration. Nurse call systems, hospital management software, and IoT-enabled patient monitoring.

-

Strict regulatory compliance. Adherence to health and safety codes, accessibility requirements, and fire protection standards.

-

Tight deadlines. Rising community healthcare needs mean delays are not an option.

Rather than issuing a simple RFQ for materials or services, the owner prepares an RFP to evaluate not only the cost but also the approach, expertise, and reliability of potential contractors.

Vendors are asked to provide:

-

A detailed construction methodology, including sequencing of critical system installations like surgical theater ventilation.

-

A schedule with milestones, showing how the project will meet the aggressive deadline without compromising safety.

-

Quality assurance and safety plans, with particular focus on infection control and sensitive hospital zones.

-

A comprehensive cost breakdown, separating labor, materials, and contingency allowances for transparency.

By collecting and comparing these structured proposals, the project owner can identify which contractor offers the best overall value, not necessarily the lowest price, but the team most capable of delivering a compliant, safe, and timely hospital.

RFQ Meaning in Construction

A

Request for Quotation (RFQ) in construction is a formal document used to solicit price offers for well-defined goods, services, or tasks. Unlike an RFI, which gathers general information, or an RFP, which evaluates complex solutions, an RFQ is focused almost entirely on cost and delivery terms. It is most effective when the project scope is already finalized and the buyer knows exactly what is needed.

In practical terms, an RFQ might be sent out when a contractor requires:

-

Bulk materials such as cement, steel, or ready-mix concrete.

-

Rental of specific equipment like cranes, scaffolding, or generators.

-

Clearly defined subcontractor work, such as electrical wiring, painting, or plumbing.

What makes an RFQ distinct is its emphasis on price transparency and comparability. Suppliers are asked to submit detailed quotes that include unit costs, quantities, delivery timelines, and any applicable terms. By structuring the request, the contractor can easily line up multiple supplier responses side by side, ensuring a competitive and fair evaluation process.

By centering the conversation on cost and logistics, RFQs give construction firms the ability to secure accurate, competitive pricing while avoiding hidden charges or vague proposals. They are an essential tool for ensuring budget control and building trust with suppliers through a transparent process.

Reduce costs and avoid shortages

Optimize procurement with FirstBit

Request a demo

RFQ in Construction: When To Use and What To Include

A Request for Quotation (RFQ) is most valuable when the requirements are specific, measurable, and well-defined. Unlike RFIs and RFPs, which involve exploration and strategy, RFQs work best once the project has a clear scope and the buyer is simply seeking the best price for exact deliverables.

When to Use an RFQ in Construction

Contractors typically issue an RFQ in situations where precision and cost control matter most:

-

Bulk material procurement. For example, purchasing 500 cubic meters of ready-mix concrete, where specifications and volumes are already known.

-

Equipment rental. Such as hiring a tower crane for six months with a specified lifting capacity.

-

Standardized subcontractor services. Tasks like interior painting, floor tiling, or insulation, where the scope and quality benchmarks are clearly documented.

-

Well-defined outsourced services. For instance, hiring a surveying firm to conduct geotechnical testing using standardized methods.

In each of these cases, issuing an RFQ ensures suppliers compete on a level playing field, allowing project owners to secure cost-effective and timely solutions.

What to Include in an RFQ in Construction

For an RFQ to produce accurate, comparable quotes, it must be structured and detailed. A strong RFQ typically includes the following elements:

-

Project and contractor information. The project name, site location, and the buyer’s company details, so vendors know who they’re dealing with.

-

Detailed scope of work or materials. Itemized lists of goods or services required, along with exact specifications, drawings, or standards to avoid ambiguity.

-

Quantities and dimensions. Clear figures for material volumes, equipment capacities, or labor hours expected.

-

Delivery or completion schedule. Specific dates when materials should arrive on site or services must be completed.

-

Commercial terms. Payment milestones, penalties for late delivery, warranty requirements, and packaging or shipping conditions.

-

Submission instructions. Clear guidance on how and where suppliers should submit their quotations, whether through a bidding portal or a project management platform.

-

Deadline for submission. A firm cutoff date and time to maintain fairness and keep procurement timelines on track.

By including these components, contractors minimize misunderstandings, facilitate easier comparison of supplier responses, and establish a reliable paper trail for procurement audits.

Example

Consider a contractor preparing for the foundation phase of a mid-rise residential project. The structural drawings specify 500 cubic meters of M25 grade ready-mix concrete to be delivered in batches over two weeks. The contractor already has clear details: the mix design, slump requirements, delivery schedule, and pumping needs.

Instead of asking vendors for proposals on how they would execute the work (which would be the case with an RFP), the contractor issues an RFQ focused purely on pricing and delivery terms. Each supplier is asked to submit:

-

A per-cubic-meter rate for the specified concrete grade.

-

Transportation charges, including distance-based surcharges if applicable.

-

Availability of transit mixers and pumps to meet the timeline.

-

Payment terms, warranties for quality, and penalties for delayed deliveries.

By collecting responses from multiple suppliers in this structured format, the contractor can compare all offers side by side. The decision is based not only on unit price, but also on delivery reliability and service conditions, ensuring that the concrete supply aligns seamlessly with the construction schedule.

RFQ vs RFP vs RFI

In construction procurement, RFIs, RFPs, and RFQs are often used together but serve very different purposes. Understanding their distinctions helps project teams apply the right request at the right stage, whether exploring options, evaluating solutions, or locking in pricing.

Purpose and Procurement Phase

-

RFI (Request for Information). It's used early in a project when the scope is still evolving. The goal is to explore what solutions, technologies, or capabilities exist in the market.

-

RFP (Request for Proposal). It's issued when requirements are defined, but the owner is looking for detailed methods and value-based solutions. Proposals are evaluated on more than just cost.

-

RFQ (Request for Quotation). It's sent once specifications are finalized and the main decision factor is cost. It focuses on pricing, terms, and delivery commitments.

Level of Detail and Commitment

-

RFI. Informal, exploratory, and non-binding. Suppliers share knowledge rather than firm offers.

-

RFP. Formal and detailed. Vendors commit to approaches, schedules, and pricing assumptions.

-

RFQ. Highly structured, requesting specific prices and terms, often forming the basis for a contract.

Evaluation Criteria (Capability, Cost, Value)

-

RFI evaluates general capability and gathers insights into vendor expertise.

-

RFP balances cost with methodology, quality standards, and project-specific value.

-

RFQ compares supplier prices, delivery schedules, and commercial terms side by side.

|

Aspect

|

RFI (Info)

|

RFP (Proposal)

|

RFQ (Quote)

|

|

Goal

|

Explore and learn

|

Compare solutions and execution plans

|

Confirm pricing and delivery terms

|

|

When to use

|

Early unclear scope

|

Mid–defined needs, multiple solution options

|

Late – ready to purchase

|

|

Focus

|

General capabilities, market knowledge

|

Project-specific methods, value, and compliance

|

Pricing, quantities, and timelines

|

|

Tone

|

Informative and open-ended

|

Structured and vendor-directed

|

Detailed and price-focused

|

|

Output

|

Market insights

|

Competitive proposals with detailed breakdowns

|

Price comparisons for procurement

|

How They Work Together

RFIs, RFPs, and RFQs should not be viewed as standalone steps, but as part of a procurement workflow:

-

An RFI helps define the need by collecting broad market knowledge.

-

An RFP evaluates how different vendors propose to meet that need, balancing cost with quality and methodology.

-

An RFQ finalizes the process by confirming exact prices and delivery terms for the chosen scope.

When used sequentially, these tools create a transparent, structured approach to vendor selection, reducing risk and ensuring better alignment between project requirements and supplier capabilities.

Ensure timely and profitable project completion with FirstBit

Request a demo

Seamless Workflow Across RFI, RFQ, RFP in One FirstBit ERP Platform

Managing RFIs, RFPs, and RFQs separately can quickly become overwhelming, especially when dealing with multiple projects, subcontractors, and suppliers.

FirstBit ERP simplifies this process by centralizing procurement and communication within a single platform.

Centralized Request Management

Instead of juggling scattered spreadsheets, emails, and attachments, project teams can create, send, and track RFIs, RFPs, and RFQs directly in FirstBit ERP. Each request remains tied to its project, ensuring that no document is misplaced and every communication is logged.

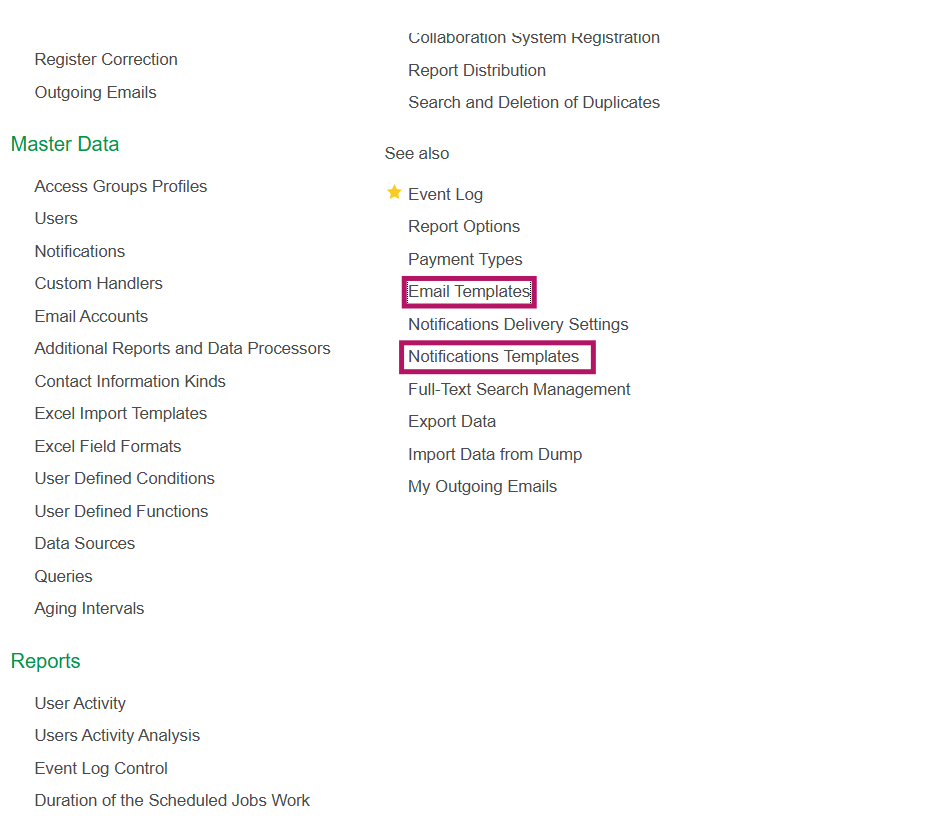

Built-in Document Templates

FirstBit ERP includes standardized templates for procurement requests. These templates help ensure consistency across projects, reduce errors, and save time compared to manually preparing each document from scratch.

Email and notifications templates in FirstBit ERP

Integrated Budget and Cost Control

All procurement requests in

FirstBit ERP are directly connected to project budgets and cost codes. This integration ensures that incoming proposals or quotes are aligned with approved financial plans. Managers can see immediately how a supplier’s response will affect the project’s budget in real time.

Real-Time Supplier Comparison

When multiple suppliers submit responses,

FirstBit ERP allows side-by-side comparison of pricing, delivery terms, and compliance with specifications. This eliminates the need for manual data entry and ensures that decisions are based on accurate, up-to-date information.

Automated Communication and Approvals

The platform automates key steps such as sending clarifications, issuing addenda, and routing approvals to the right decision-makers. This not only speeds up the procurement cycle but also ensures accountability, since every step is recorded in the system.

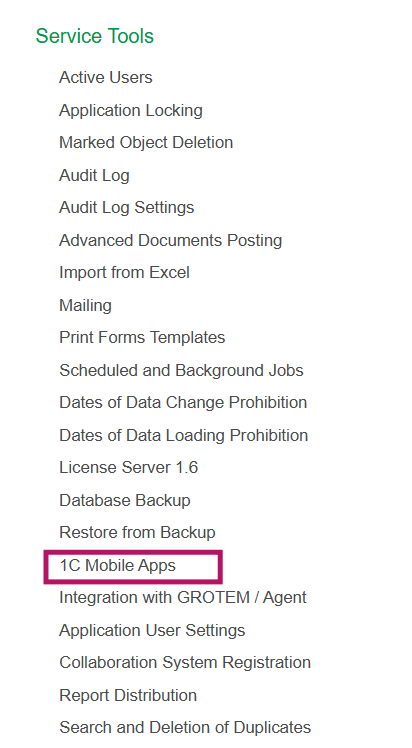

Cloud Access and Mobile App

Because FirstBit ERP is cloud-based and has a mobile app, project managers and procurement officers can issue requests, review submissions, and approve contracts from the office, on-site, or while traveling. This mobility helps keep projects moving without delays caused by location or timing constraints.

Mobile app feature in FirstBit ERP

Conclusion

Navigating RFIs, RFPs, and RFQs effectively is about more than just sending documents—it’s about creating a structured process that supports transparency, accuracy, and smarter decision-making. Each request plays a distinct role in the procurement cycle: RFIs explore possibilities, RFPs evaluate solutions, and RFQs finalize costs. When handled in isolation, these steps can become disjointed and time-consuming.

By using an integrated platform like

FirstBit ERP, construction companies can connect these requests into one seamless workflow. Instead of working in silos, every stage from gathering initial information to securing the final price is tracked, aligned with budgets, and accessible in real time. This not only saves time and reduces errors but also helps companies build stronger supplier relationships and deliver projects with greater financial control.

In today’s competitive environment, firms that master procurement efficiency gain an edge. Understanding when to use each type of request and managing them through a unified system turns procurement into a strategic advantage rather than just an administrative task.

Choose the best suppliers

Compare quotes side‑by‑side, evaluate cost and quality with FirstBit ERP

Request a demo

FAQ

What does RFI mean in construction?

RFI stands for Request for Information. It is used in the early stages of a project to gather general, non-binding information from vendors or subcontractors before detailed requirements are set.

What is the purpose of an RFI in construction?

The purpose of an RFI is to explore market options and understand what products, services, or capabilities are available. It helps contractors and clients evaluate potential vendors before moving to RFPs or RFQs.

What is RFP in construction?

RFP stands for Request for Proposal. It is used when project owners want detailed vendor proposals covering scope, cost, timelines, and methodology. RFPs are ideal for complex projects that require customized solutions.

What is RFQ in construction, and how is it different from RFP?

RFQ stands for Request for Quotation. It is used when project requirements are already defined, such as exact quantities and specifications, and the goal is to compare prices. Unlike an RFP, it focuses only on pricing and terms, not on detailed execution strategies.

Umme Aimon Shabbir

Editor at First Bit

Aimon brings a deep understanding of the modern construction business to her articles by providing practical content.