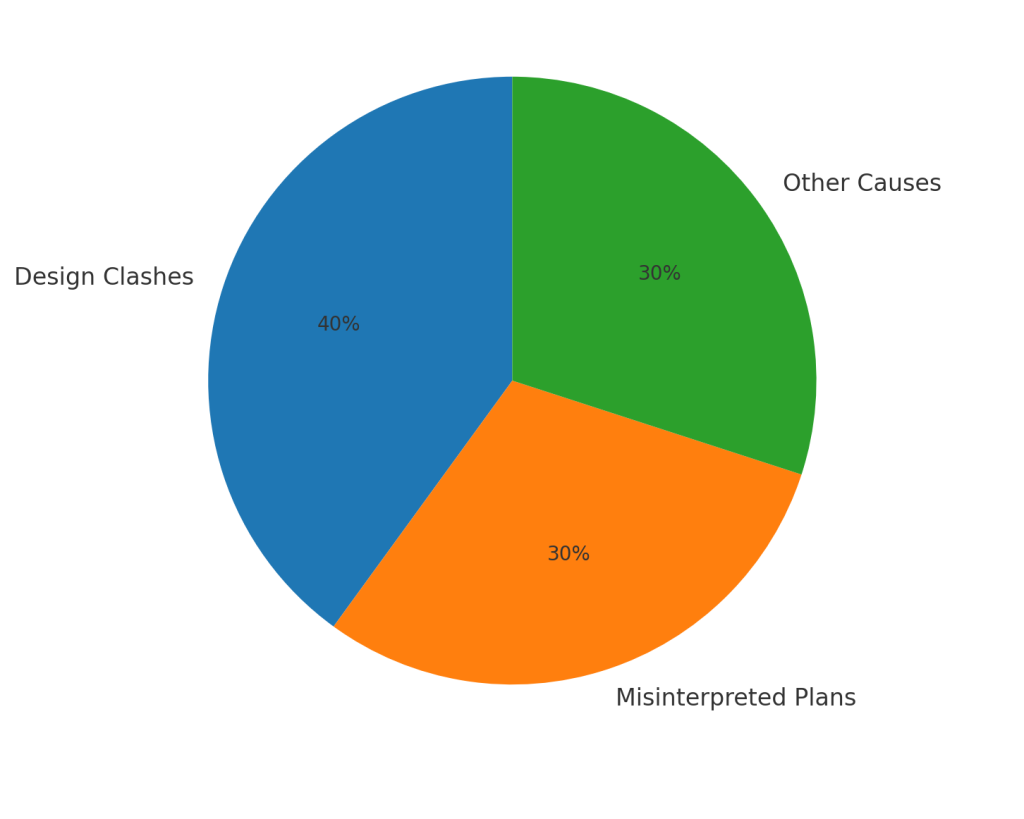

Rework or correcting completed construction work is one of the industry’s most expensive hidden costs. It often stems from design clashes, misinterpretations of plans, or missed quality checks, and can eat up significant time and resources.

One study found that rework alone reduced a contractor’s annual profit by nearly 28%.[?]

This is how rework can reduce a contractor’s annual profit

Augmented Reality (AR) provides a solution to address this issue at its root. By overlaying digital models onto physical job sites, AR helps teams visualize designs in real time, detect errors before they happen, and verify work as it’s completed.

This article explores how AR is helping construction firms prevent costly mistakes and why it’s quickly becoming an essential tool for modern project management.

Why AR is Becoming Essential in Modern Construction Projects

Construction projects

frequently encounter challenges such as design discrepancies, misinterpreted specifications, and delays caused by poor coordination. These issues often lead to costly rework, schedule overruns, and strained project resources — problems that continue to impact profitability across the industry.

A recent case study involving multiple U.S. contractors highlighted that augmented reality (AR) is rapidly becoming an essential tool for modern construction projects. Contractors reported using AR for quality assurance, clash detection, and real-time visualization, enabling teams to double-check work, detect installation conflicts, and collaborate remotely with experts. While some limitations remain — such as model accuracy and hardware comfort — the technology has already saved man-hours and improved decision-making.[?]

Miscommunication and design errors have long plagued construction projects, often leading to costly rework and delays. These issues not only impact budgets and schedules but also strain collaboration between teams and stakeholders.

The case study showed that AR is already being used by contractors for quality assurance, clash detection, and project visualization, helping teams catch issues early and improve coordination. Experts noted that AR is especially valuable on large and complex projects, where its ability to overlay digital models onto real-world sites provides a tangible competitive advantage.

These capabilities translate into several key advantages for modern construction workflows:

It Brings Designs to Life in the Real World

Flat blueprints can be tricky to interpret. Augmented reality in construction brings designs to life by overlaying 3D models into real-world sites. This helps teams spot issues early, saving time and reducing costly revisions.

ERP that saves your money

Adopt FirstBit ERP to cut costs, boost ROI, and effectively plan future cash flows

Request a demo

AR Accelerates Client Decision-Making

Clients may find it hard to picture a project from drawings alone. AR in construction offers an immersive preview, letting them explore a virtual structure before it’s built. This speeds up decisions and ensures the final build matches their vision.

Enhances Collaboration Across Distributed Teams

With teams often spread across locations, alignment can be tough. Augmented reality in construction creates a shared digital space, allowing everyone — from architects to contractors — to work from the same model, cutting down on errors.

Choose the right technology for your construction business

Request a demo

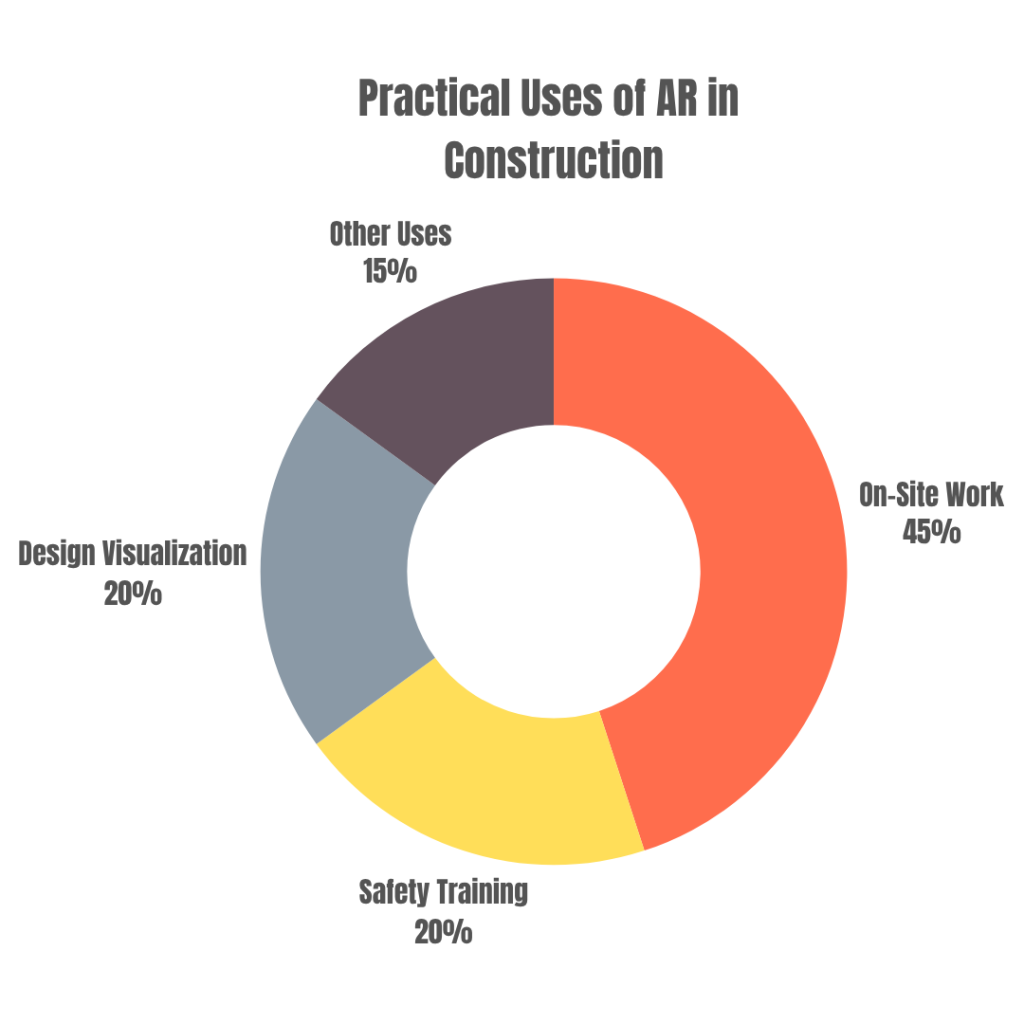

Practical Uses of AR in Construction

AR’s true value in construction becomes most evident when we look at how it’s applied at different stages of a project. By connecting digital models directly to physical worksites, AR helps teams work more accurately and collaboratively — from the earliest design decisions to long-term maintenance.

Studies show that 45% of AR applications in infrastructure focus on on-site work, highlighting its growing role beyond just planning.[?]

These applications demonstrate how AR supports real-world workflows:

-

Design visualization. Converting 2D plans into interactive 3D models for clearer design reviews and refinements.

-

Site planning. Virtually laying out equipment and structures to optimize space and improve safety.

-

Execution. Providing workers with real-time data, such as measurements, directly overlaid on the site for higher precision.

-

Quality checks. Comparing completed work against plans to catch deviations early.

-

Maintenance. Overlaying repair and inspection plans onto existing structures to simplify upkeep.

Key Use Cases of AR in Construction Planning and Execution

From initial design reviews to final inspections, AR applications are helping teams work more efficiently and reduce costly errors. Let's explore the most impactful ways construction professionals are using this technology today.

Transform your business

Embrace innovation with FirstBit ERP

Request a demo

Design Visualization and Review

With AR technology, digital building models can be overlaid directly onto the physical job site. This gives architects, engineers and subcontractors a clear view of how the finished structure will look, helping teams align early and reduce design errors.

This enhanced visualization offers several powerful advantages:

-

Boosted сlient buy-in. Instead of spreading out complex blueprints, hand clients AR headsets so they can experience their future building at full scale. They'll see exactly how their space will look and feel before you pour the first foundation.

-

Reduced design changes. Project managers using this approach report dramatically fewer design changes and client revisions later in the process, saving you both time and money.

-

Early conflict detection. Visualize how different building systems interact in 3D space to spot conflicts that traditional drawings miss, enabling you to resolve issues during the planning phase rather than discovering them mid-installation when changes become expensive problems.

Enhanced Project Documentation and Progress Tracking

Imagine being able to document your project progress with photos that automatically capture relevant data, timestamps and exact location information. With AR-enabled tablets or smartphones, your workers can create a detailed visual record of your construction activities.

When you need to track progress against schedules, you can overlay digital timelines directly onto real-world conditions. This eliminates the need for guesswork or disputes, as you have clear visual documentation of the work that was carried out and the date it was completed. During inspections or client meetings, you can instantly access this documented proof.

Your on-site teams can also see digital milestone markers overlaid on construction elements, providing visual confirmation that quality standards have been met at each stage before moving forward. This prevents costly rework and ensures that nothing is missed in the construction sequence.

Protect your data with cloud backups

Request a demo

Real-Time Collaboration Between Remote Teams

Construction teams no longer need to be in the same location to collaborate effectively. AR applications enable live views of the construction site to be shared with remote engineers, architects and project managers, bringing their expertise directly to on-site crews.

During these virtual sessions, your remote team members can annotate the live video feed in real-time, pointing out specific areas that need attention or guiding workers through complex installations. This means you can resolve issues immediately without waiting days for specialists to travel to your job site.

You can also improve coordination between different trades on your project. When your electricians leave AR markers showing installed conduits, your plumbers and HVAC technicians can see exactly where everything is located, preventing conflicts and reducing the need for costly rework.

Safety Training and Hazard Identification

AR simulations allow workers to practice responding to equipment failures, structural collapses, or chemical spills in realistic 3D environments—delivering immersive safety training without real-world risk.

Recent research conducted with 72 participants during metro construction projects demonstrated that AR training significantly improves workers' ability to identify safety risks in the short term, proving more effective than traditional safety training methods.[?]

On active job sites, AR safety applications overlay warnings and hazard markers directly into workers’ field of view, highlighting areas requiring fall protection, marking underground utility locations, or displaying real-time air quality readings in confined spaces. These features keep crews informed and protected.

Virtual safety walks can also be conducted remotely, with safety managers inspecting job sites through AR-enabled devices. This approach allows for more frequent safety reviews without disrupting ongoing work, helping to catch potential problems before they escalate into incidents.

ERP that saves your money

Adopt FirstBit ERP to cut costs, boost ROI, and effectively plan future cash flows

Request a demo

Equipment Operation and Maintenance Guidance

AR technology provides heavy equipment operators with step-by-step visual guidance, showing optimal digging methods, load capacities and positioning requirements directly in their field of view. When maintenance is required, AR overlays digital instructions onto the machinery itself, reducing repair time and ensuring proper procedures are followed.

Operators benefit from enhanced precision, as AR applications display ideal load positioning, excavation depths and underground utility locations. This accuracy reduces the risk of costly mistakes and safety incidents during operation.

Quality Control and Inspection Processes

Your quality control inspectors can overlay digital building models onto completed work, instantly identifying any deviations from the planned design. With BIM integration, they can access the detailed specifications of any component simply by pointing their device at it.

Inspection photos and videos automatically capture location data, specification references, and compliance notes, creating comprehensive records that support project close-out and warranty processes. This gives you complete visibility of work quality throughout your entire project.

AR applications are already transforming construction sites across the industry. As this technology becomes more accessible, you will see even more innovative applications that will boost your efficiency, safety, and quality standards.

Digital tools such as

FirstBit ERP can extend these AR benefits by

centralising inspection data, automating quality reports, and linking field observations to project specifications and compliance requirements. This helps teams respond quickly when defects are identified and maintain clear audit trails for accountability.

Choose the right technology for your construction business

Request a demo

How FirstBit Empowers Construction Businesses with Smart Tech

As construction companies adopt AR on-site, one challenge stands out: connecting those insights to everyday business operations. The best results come when AR tools link directly with Enterprise Resource Planning (ERP) systems, so information from the field feeds straight into budgets, schedules and purchasing.

For example, when crews use AR to document progress, flag design clashes or track material use, that data can flow into the ERP system. This keeps budgets up to date, triggers purchase orders when materials run low, and helps planners adjust schedules based on real conditions.

FirstBit ERP, designed for the construction industry, helps make this possible by connecting AR data with project teams, suppliers and finance in one place. The result is faster decisions and fewer gaps between what happens on-site and what happens in the office.

F.A.Q.

How accurate is AR-based layout positioning compared to traditional laser tools?

AR-based layout positioning typically achieves accuracy within 1-5mm range under optimal conditions, which is comparable to mid-range laser tools but generally less precise than high-end total stations or robotic theodolites that can achieve sub-millimeter accuracy.

However, AR positioning offers significant advantages in speed, ease of use, and real-time visualization that often outweigh the slight precision trade-off for most construction layout tasks, especially when combined with proper calibration and quality control procedures.

How does AR handle constantly changing site conditions in live projects?

AR systems continuously adapt to changing site conditions using dynamic tracking algorithms that recalibrate against fixed reference points, GPS coordinates, and visual markers. When these systems detect environmental changes — such as moved equipment or new structures — they automatically prompt users to re-anchor the digital model.

Are AR tools compatible with locally used BIM formats in the GCC construction sector?

AR tools are generally compatible with standard BIM formats commonly used in the GCC construction sector, including IFC, Revit, AutoCAD, and Tekla files. Most leading AR platforms support direct import from major BIM software like Autodesk, Bentley, and Trimble systems that are widely adopted across the region.

However, some proprietary or legacy formats may require conversion through intermediate software, and complex models might need optimization to ensure smooth performance on mobile AR devices used in field conditions.

Is it difficult to incorporate AR technologies into existing workflows?

Addressing this concern assures clients that integrating AR won’t disrupt their operations. Emphasizing user-friendly tools and support reduces hesitation and encourages adoption by showcasing ease of implementation.

Is it possible to rent AR equipment instead of buying it?

Yes, it is possible to rent AR equipment instead of buying it. For smaller companies or those testing AR, rental options make the technology more accessible and reduce upfront financial risk. This flexibility allows businesses to explore AR without committing to a full purchase until they are ready.

Transform your business

Embrace innovation with FirstBit ERP

Request a demo

Anna Fischer

Construction Content Writer

Anna has background in IT companies and has written numerous articles on technology topics.