Every successful construction project relies on precise numbers. But without a clear method to gather supplier pricing,

cost control quickly unravels. That’s where the request for quotation in construction (RFQ) process becomes indispensable. By standardizing how contractors and suppliers respond to pricing requests, companies avoid guesswork and gain a reliable basis for comparison.

Research by McKinsey shows that construction companies adopting structured procurement practices can achieve up to 12% in cost savings across sourcing functions[?].

In an industry where budgets are tight and margins thin, a disciplined RFQ process is not just administrative, it’s a competitive advantage. The companies that master it are the ones that keep projects profitable, avoid disputes, and strengthen supplier relationships.

What Are Quote Requests in Construction?

A quote request in construction (RFQ) is a formal document used to collect pricing for materials, equipment, or subcontracted services. Its purpose is to remove ambiguity by ensuring that all vendors respond to the same set of requirements. This allows contractors to compare quotes fairly and select the option that best fits the

project’s budget and schedule.

Typically, an RFQ in construction includes:

-

Project scope. A clear description of the work or materials required.

-

Specifications. Technical details such as dimensions, material grades, or quality standards.

-

Quantities. The exact number of items or volume of materials needed.

-

Delivery requirements. Deadlines, shipping terms, and site conditions.

-

Payment terms. Details about deposits, schedules, or conditions tied to milestones.

By formalizing these details, RFQs serve three purposes: they enhance cost accuracy, foster transparency in supplier selection, and provide a record that can be referred back to in the event of disputes. For construction companies, this process is essential not just for cost control, but also for maintaining credibility with clients and stakeholders.

Importance of Quote Requests in Construction

Importance of quote requests in construction

In the construction industry, projects succeed or fail on details. A well-prepared request for quotation in construction (RFQ) brings structure and accountability to procurement, ensuring that costs, timelines, and quality expectations are clear from the outset. Far from being just a routine document, an RFQ can shape the financial stability and efficiency of an entire project.

Here’s why RFQs are so important:

Cost Efficiency

With materials and labor making up the majority of project costs, even small discrepancies can affect profitability. By issuing a structured RFQ, contractors invite multiple vendors to compete on equal terms.

This competitive environment pushes suppliers to provide sharper prices while ensuring that bids reflect the same requirements. Over time, this practice not only lowers unit costs but also gives contractors stronger benchmarks to use in future negotiations.

Transparency

Cost disputes are common in construction when expectations aren’t documented clearly. An RFQ eliminates ambiguity by defining exactly what is needed, whether that’s cubic meters of concrete, electrical wiring specifications, or delivery deadlines.

Every supplier responds to the same criteria, creating a transparent record that protects both sides if disagreements arise later. This transparency is particularly valuable for public projects where accountability is non-negotiable.

Quality Assurance

Low costs are meaningless if materials or services fail to meet standards. By spelling out compliance requirements, certifications, or quality benchmarks within the RFQ, contractors ensure vendors can’t cut corners without detection. For example, specifying “reinforced steel conforming to ASTM A615 standards” leaves no room for misinterpretation. This level of detail greatly reduces the risk of delays caused by substandard materials or corrective rework.

Time Savings

Procurement delays often ripple into construction delays. A well-prepared RFQ speeds up supplier selection by providing all the details vendors need to quote correctly the first time. Instead of chasing clarifications or revising incomplete bids, contractors can evaluate accurate, comparable quotes side by side.

Many firms now rely on digital RFQ templates that further accelerate the process by automating distribution, reminders, and response tracking.

Stronger Supplier Relationships

Consistency builds trust. When suppliers see that contractors use a professional, repeatable RFQ process, they know the evaluation is based on merit rather than subjective preference. This encourages vendors to provide their best pricing and service, knowing they are being treated fairly.

Over time, such transparency leads to stronger partnerships, faster responses, and better service, particularly with suppliers who value long-term collaboration.

Improved Planning

Accurate supplier quotes don’t just inform cost, they also provide critical scheduling data. Delivery lead times, production capacities, and resource availability all become visible through the RFQ process. This allows project managers to align procurement with construction milestones, ensuring that materials arrive when needed and crews aren’t left idle. Better planning directly translates to fewer delays, reduced downtime, and smoother cash flow management.

Reduce costs and avoid shortages

Optimize procurement with FirstBit

Request a demo

When Do You Request a Quotation in Construction

Not every stage of a project calls for an RFQ. These requests are most effective when the requirements are specific, the deliverables are measurable, and pricing is the key factor in selecting a vendor. In construction, this typically applies to straightforward procurement needs and well-defined tasks where suppliers can provide competitive and comparable offers.

Some common situations include:

1. Contracting Outsourced Services

Services like site surveys, material testing, or safety audits are also ideal for RFQs when deliverables are straightforward and measurable. For example, a developer preparing a new industrial park might issue an RFQ for soil testing services, specifying the number of boreholes and testing standards required. Vendors then respond with clear pricing and timelines, giving the developer confidence in both cost and compliance.

2. Procuring Construction Materials

When a project requires bulk purchases of items like cement, steel, or aggregates, an RFQ helps contractors compare supplier prices on identical specifications and lock in competitive rates. For instance, a mid-rise residential project allows multiple suppliers to respond with precise bids. The contractor can then compare not only costs but also delivery timelines and payment terms, ensuring the choice balances price with reliability.

3. Hiring Subcontractors for Defined Tasks

RFQs work well when the scope is narrow, such as electrical wiring, plumbing, or flooring. In a hospital construction project, for example, an RFQ may be issued for installing HVAC ductwork across a single wing. Since the task is well-defined, subcontractors can quote labor and material costs accurately, and the project team can evaluate offers without confusion over scope.

4. Renting Specific Equipment

Equipment rental needs are often standardized, making RFQs highly effective. A contractor building a bridge might issue an RFQ for a 50-ton crane rental for three months. By detailing lifting capacity, availability dates, and service requirements, the RFQ ensures bids are directly comparable, saving both time and money.

What To Include in a Construction Quote Request

An RFQ in construction is more than a request for prices; it is a structured document that sets the foundation for fair competition and reliable project delivery. The quality of the RFQ directly influences the quality of responses contractors receive. A vague request leads to inflated bids, unclear terms, and disputes later on. A detailed RFQ, by contrast, produces accurate and comparable quotes that save both time and money.

Project and Contractor Information

Every RFQ should begin with clear project details. This typically includes the project’s name, location, scope of work, and a short description that frames the overall requirement.

Contractor information is equally important—your company’s legal name, address, and contact details should be clearly provided so suppliers know exactly who they are dealing with. Designating one primary contact person ensures vendors have a consistent channel for clarifications.

For example, if you are building a mid-rise residential project in Dubai, the RFQ might specify:

“Project: Al Noor Residences, 10-floor residential tower, located in Business Bay, Dubai. Scope: Supply of reinforced concrete and structural steel as per attached drawings.”

This leaves no ambiguity about what the request relates to.

Tip: Always include a reference or RFQ number on the document. It helps track submissions and avoids confusion when multiple RFQs are issued at once.

Required Work or Materials

This section is the backbone of the RFQ. It must detail the exact goods or services being requested, along with specifications. For materials, this means grades, standards (e.g., ASTM or BS codes), brand preferences, and performance requirements. For subcontracted works, the RFQ should specify deliverables, work methods if required, and compliance obligations.

A well-written RFQ doesn’t just say “steel bars”, it specifies:

“12 mm TMT bars, Grade 500, cut and bent as per drawings, delivered in bundles of 1,000 kg.”

Similarly, for services like HVAC installation, outline scope elements such as ducting, insulation, testing, and commissioning. The more specific the RFQ, the easier it is for suppliers to provide accurate and competitive pricing.

According to PMI’s Pulse of the Profession, 47% of project failures are linked to poor requirements definition, underscoring the importance of precise RFQs[?].

Adding this level of detail not only produces more reliable quotes but also reduces the risk of disputes after the contract is awarded. Suppliers appreciate clarity, as it allows them to quote with confidence and reduces the need for multiple rounds of clarification.

Tip: Provide the list of items or services in a tabular format with columns for item name, quantity, technical description, and unit. This makes supplier responses consistent and easier to evaluate.

Quantities and Dimensions

Without precise quantities, no vendor can give a reliable price. State the exact numbers, units of measurement, and tolerances. Where applicable, include drawings, take-off sheets, or BOQs (Bills of Quantities) to support accuracy.

For example, instead of writing “tiles for lobby flooring,” specify:

“Porcelain tiles, 600x600 mm, Grade A, quantity 1,200 m², with skirting.”

This level of detail eliminates guesswork and ensures bids are directly comparable.

Tip: Avoid using terms like “approx.” or “as required” unless absolutely necessary. These leave room for interpretation and almost always result in disputes or inflated costs later.

Schedule or Delivery Timeline

The RFQ must outline when the requested goods or services are needed. For materials, provide delivery schedules and site restrictions (e.g., “deliveries allowed only between 8 am and 5 pm”). For services, specify the expected start and completion dates, as well as any interface requirements with other trades.

For instance, a request for scaffolding might state:

“Supply and erection of scaffolding for façade works. Required on-site by March 15, 2025, for a duration of six months, including monthly safety inspections.”

This enables vendors to plan resources and logistics properly.

Tip: Ask vendors to state their own lead times and availability. This not only helps evaluate bids but also gives an early warning if schedules are unrealistic.

Commercial Terms

Pricing alone doesn’t determine the best bid—commercial terms shape the actual cost and risk. Common inclusions are payment terms (e.g., 30 days after invoice), penalties for late delivery, warranties, insurance requirements, and shipping conditions (e.g., CIF, FOB). By setting these up front, you avoid surprises after the award.

For example, if warranty coverage is critical, state:

“Supplier must provide a minimum 12-month warranty against manufacturing defects.”

Without such clarity, a vendor might submit a cheaper bid but later refuse responsibility when defects appear.

Tip: Standardize payment and delivery terms across RFQs wherever possible. This makes comparison between vendors straightforward and saves time during evaluation.

Submission Instructions

Clear submission guidelines help suppliers know exactly how and where to send their quotations, ensuring consistency and avoiding missed deadlines. Instead of leaving it open-ended, define the preferred format, for example, requiring a structured RFQ template in Excel or PDF. You can also specify whether responses should be uploaded to a centralized procurement portal, submitted through a bidding platform, or delivered via a secure document management system.

Standardizing submissions makes it much easier to compare offers side by side, since all vendors follow the same structure. This reduces back-and-forth communication and helps project managers evaluate quotes fairly and quickly.

Providing structured instructions ensures no detail is overlooked and all vendors compete on an equal footing.

Tip: Always specify the acceptable file format (e.g., PDF or Excel) and mention any mandatory supporting documents like certifications, references, or product data sheets. This minimizes incomplete submissions and saves time during evaluation.

Quote Submission Deadline

The final critical element is the submission deadline. State the exact date, time, and time zone. Also, mention whether late submissions will be disqualified or considered under special circumstances.

For instance: “All quotes must be received no later than 3:00 PM (GST), February 28, 2025. Late submissions will not be evaluated.”

This sets clear boundaries and demonstrates fairness in the bidding process.

Tip: Allow reasonable time for vendors to prepare thorough responses. Unrealistically short deadlines often lead to mistakes or inflated prices.

Bringing all these elements together transforms a simple request into a structured RFQ that leaves no room for misinterpretation. By clearly defining scope, timelines, commercial terms, and submission guidelines, contractors can evaluate supplier quotes on equal terms and select the option that best aligns with project goals. A well-prepared RFQ not only improves accuracy and transparency but also builds stronger relationships with vendors, setting the stage for smoother procurement and execution.

Get top-quality materials at the best prices for your construction project

Request a demo

How To Request a Quotation in Construction: Step-by-Step Process

Requesting a quotation in construction isn’t just about sending an email to a supplier and waiting for a price. It’s a structured process designed to ensure fairness, accuracy, and transparency. Each step builds toward selecting the right vendor while keeping costs under control and timelines realistic.

Draft the RFQ

The process begins with drafting a comprehensive RFQ document. This is the foundation of the entire exercise and should clearly define:

-

Project scope. Clearly explain what the job entails and outline its objectives in detail.

-

Required materials or services. Provide an itemized list that includes complete specifications for each material or service.

-

Quantities and dimensions. State exact figures and measurements so suppliers can price accurately without guesswork.

-

Deadlines. Specify clear dates for delivery or completion to set realistic expectations upfront.

By laying out these details from the start, suppliers are able to prepare accurate and comparable quotes, reducing the risk of misunderstandings later.

Share the RFQ With Suppliers

Once the RFQ is prepared, it should be distributed to a shortlist of qualified suppliers or subcontractors. The method of sharing depends on the systems in place—many firms now rely on cloud-based construction management platforms to issue RFQs and track responses.

When deciding who to send the RFQ to, consider the following:

-

Supplier qualifications and certifications. Check that suppliers meet the technical and compliance standards required for your project.

-

Past performance on similar projects. Evaluate suppliers’ track records to gauge their reliability and quality of work.

-

Capacity to meet delivery schedules. Confirm that suppliers have the resources and availability to meet your project’s timeline.

Selecting vendors carefully at this stage improves the quality of quotes received and ensures the evaluation process is more straightforward.

Collect and Evaluate Quotes

As suppliers respond, their submissions need to be reviewed systematically. This evaluation is not limited to price alone, but should cover several critical areas:

-

Pricing structure. Ensure that cost breakdowns are transparent, detailed, and complete, leaving no room for hidden charges.

-

Delivery timelines. Assess whether the proposed schedules align with your project’s milestones and critical deadlines.

-

Quality standards. Verify that the submissions comply with technical specifications and relevant regulatory requirements.

-

Service commitments. Review warranties, after-sales support, and any penalties for delays that vendors are offering.

Using a comparative table or matrix can help visualize differences between vendors, ensuring decisions are based on transparent, objective criteria rather than assumptions.

Request Additional Information

After the first review, close any gaps before you compare prices head-to-head. Send a clear, time-bound clarification request to each vendor and keep a single Q&A log so answers are consistent across bidders. Typical clarifications include:

-

Scope and specification alignment. Confirm any deviations, equivalents, or alternate options, and request that vendors price alternates separately.

-

Inclusions and exclusions. Clarify whether the price includes delivery to the site, off-loading, installation, testing and commissioning, consumables, and spare parts.

-

Logistics. Confirm lead times, phased delivery requirements, packaging standards, access constraints, and charges for off-hour deliveries.

-

Commercial points. Ask vendors to confirm warranty length and coverage, payment milestones, applicable taxes, validity periods, and penalties for late delivery.

-

Compliance. Request necessary certifications (e.g., ASTM, BS, EN), method statements, health and safety documentation, insurance certificates, and licenses.

Issue any clarifications or addenda to all bidders at the same time, and require revised quotes to be labeled with a new revision or date so you can track what changed.

Choose the Supplier

When quotes are complete and comparable, select the supplier based on total value, not unit price alone. A structured evaluation prevents later disputes and shows the award was fair. Consider these factors:

-

Technical compliance. Verify that the supplier meets every mandatory specification and that no unapproved substitutions have been offered.

-

Schedule fit. Ensure the supplier has confirmed lead times and delivery windows that align with your project schedule, and that they have the capacity to meet phased deliveries if required.

-

Price structure. Look for transparent line items, with clear treatment of freight, duties, installation, and taxes, and check that there are no hidden surcharges.

-

Quality and reliability. Assess warranty terms, the supplier’s QA/QC process, past project performance, references, and, where relevant, sample or test certificates.

-

Service and support. Evaluate response times, spare parts availability, and the supplier’s ability to provide on-site support during start-up or commissioning.

-

Risk profile. Consider financial stability, reliance on single sources, geographic risks, and the supplier’s contingency measures in case of delays.

Document the Process

Keeping a complete audit trail is essential because it protects you during audits, speeds up future procurement cycles, and preserves lessons learned. Each stage of the RFQ should be filed with version control and stored in a structured manner.

-

RFQ pack. Store the final version of the RFQ along with any drawings or BOQs, as well as the distribution list of all suppliers who received the request.

-

Bid communications. Maintain a log of all questions and clarifications, together with every addendum issued and the acknowledgment receipts from suppliers confirming they received the updates.

-

Supplier submissions. File every supplier’s original and revised quotations, along with technical datasheets, compliance documents, and other supporting material.

-

Evaluation records. Keep the comparison matrix, scoring sheets, internal approvals, negotiation notes, and any “best and final offer” (BAFO) documentation.

-

Award documents. Store the letter of award (LOA), purchase order (PO), or contract, together with the agreed delivery schedule, warranty certificates, and insurance documents.

-

Close-out and performance. File delivery notes, non-conformance reports (NCRs) if applicable, the supplier scorecard, and lessons learned for future reference.

Finally, all of these records should be stored in a controlled repository with standard naming conventions, defined access permissions, and clear retention periods. This ensures the full RFQ package is retrievable at any time for audits and future projects.

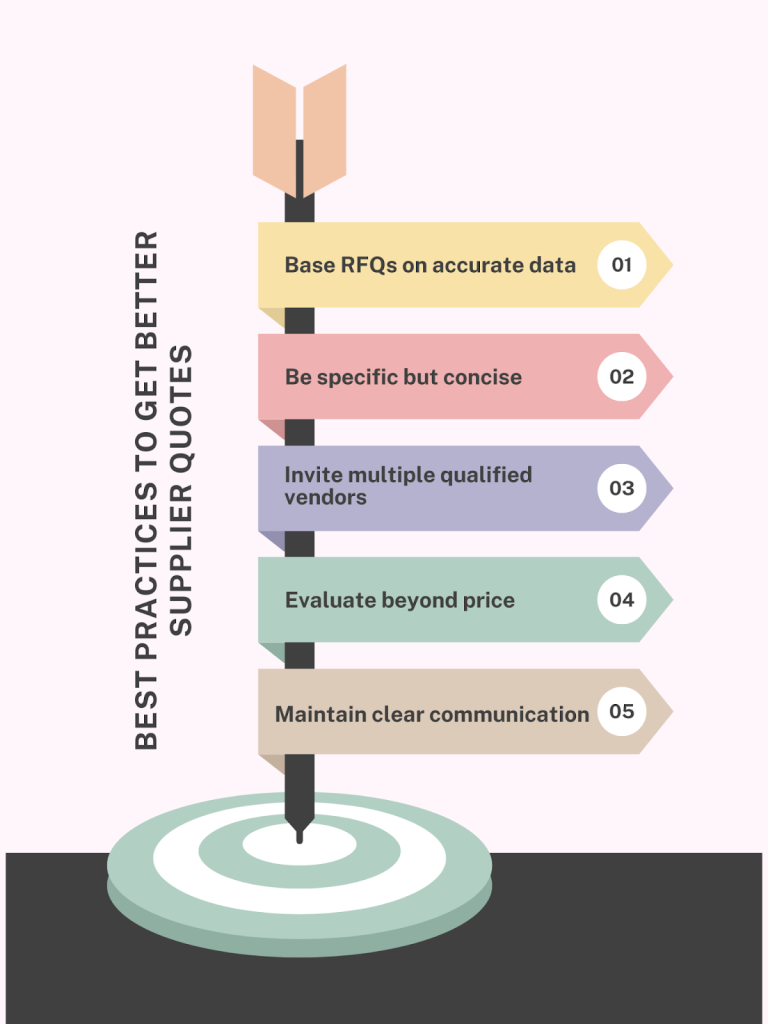

Best Practices To Get Better Supplier Quotes in Construction

Strong RFQs are the foundation of better project outcomes. They reduce disputes, speed up procurement, and save money by ensuring suppliers respond with clear, competitive proposals. Here’s how construction companies can structure their approach.

Best practices to get better supplier quotes in construction

Base RFQs on Accurate Data

One of the biggest mistakes contractors make is building RFQs on rough estimates or outdated cost assumptions. This leads to inflated supplier pricing or missed items that resurface later as costly variations.

How to apply this best practice:

-

Use historical project data. Look at similar projects you’ve completed—what were the actual material usage rates, wastage percentages, and labor productivity figures?

-

Leverage resource management tools like FirstBit ERP. These tools help track real-time consumption of materials, labor hours, and equipment usage. Pulling this data into your RFQ makes it precise and defensible.

-

Update market prices. Don’t rely on rates from last year. Verify unit rates for steel, cement, fuel, or labor based on the current market.

When suppliers see that real data backs your quantities and specs, they are less likely to pad quotes with risk contingencies.

Be Specific but Concise

Suppliers cannot price what they don’t understand. At the same time, RFQs that run into dozens of pages of unnecessary details overwhelm vendors and increase the risk of missed items.

How to apply this best practice:

-

State exactly what you need. Instead of “steel reinforcement,” specify grade, size, and applicable standards (e.g., ASTM A615 Grade 60).

-

Define timelines clearly. Mention “delivery to site by May 10th” instead of “delivery in May.”

-

Clarify packaging and delivery conditions. For example, “bundled, labeled, and delivered with offloading at the site by the supplier.”

-

Keep it readable. Break down requirements into tables or bullet lists rather than long narrative paragraphs.

This balance ensures suppliers quote accurately and eliminates the excuse of “we assumed it meant something else.”

Invite Multiple Qualified Vendors

The quality of your RFQ responses depends on who you send them to. Sending RFQs to every vendor in the directory can waste time and result in unreliable bids. Instead, focus on building a shortlist of qualified, capable suppliers.

How to apply this best practice:

-

Prequalify vendors. Ask for licenses, certifications, and proof of similar project experience before inviting them to bid.

-

Balance quality with competition. Aim for at least 3–5 vendors per package. Too few, and you reduce competition. Too many, and you drown in quotes of uneven quality.

-

Evaluate capacity. Check if the supplier can actually handle the quantities or delivery timelines you require. Past project delays are a red flag.

Healthy competition among qualified vendors keeps pricing sharp while ensuring that whoever you choose can actually deliver.

Evaluate Beyond Price

The cheapest bid can often be the most expensive mistake. Suppliers who undercut prices sometimes compromise on quality, delay deliveries, or fail to provide adequate after-sales support.

How to apply this best practice:

-

Create a weighted scoring system. Assign points not only to price but also to delivery schedule, warranty terms, service support, and compliance with technical requirements.

-

Check references. Verify past performance with other contractors or clients. Did they deliver on time? Was the quality consistent?

-

Consider life-cycle costs. A slightly higher upfront price may save money later if the product requires less maintenance or comes with a longer warranty.

Looking beyond price ensures you’re choosing long-term value, not just the lowest number on a spreadsheet.

Maintain Clear Communication

Even the most detailed RFQ will generate questions. If these aren’t addressed promptly and transparently, suppliers may submit incomplete or inflated bids to cover their risks.

How to apply this best practice:

-

Set up a Q&A log. Maintain a single clarification document and share every update with all suppliers to avoid favoritism.

-

Respond quickly. A delay in answering vendor queries shortens their time to prepare, reducing the quality of submissions.

-

Issue addenda if needed. If clarifications significantly change the scope or specs, release an official addendum to all vendors.

Strong communication not only improves quote quality but also builds trust with your supply chain, setting the stage for smoother collaboration once the contract is awarded.

Align every purchase with project goals

Track supplier performance and control costs

Request a demo

How FirstBit Helps With Getting Better Supplier Quotes in Construction

One of the recurring challenges in construction procurement is that suppliers often respond with inconsistent formats, incomplete details, or outdated prices. This slows down decision-making and increases the risk of budget overruns.

FirstBit ERP directly addresses these pain points by standardizing and streamlining the RFQ process.

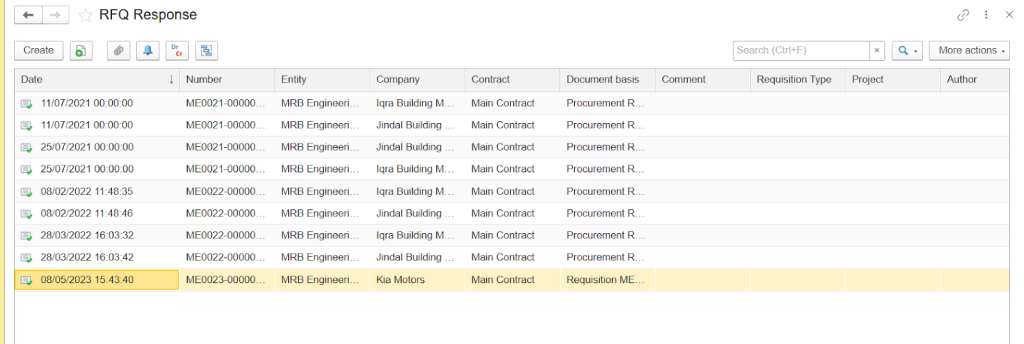

Centralized RFQ Management

With FirstBit ERP, contractors no longer need to juggle multiple spreadsheets or scattered emails. RFQs are created, shared, and tracked within one system, ensuring that every request and response remains documented and easy to compare.

RFQ dashboard within FirstBit ERP

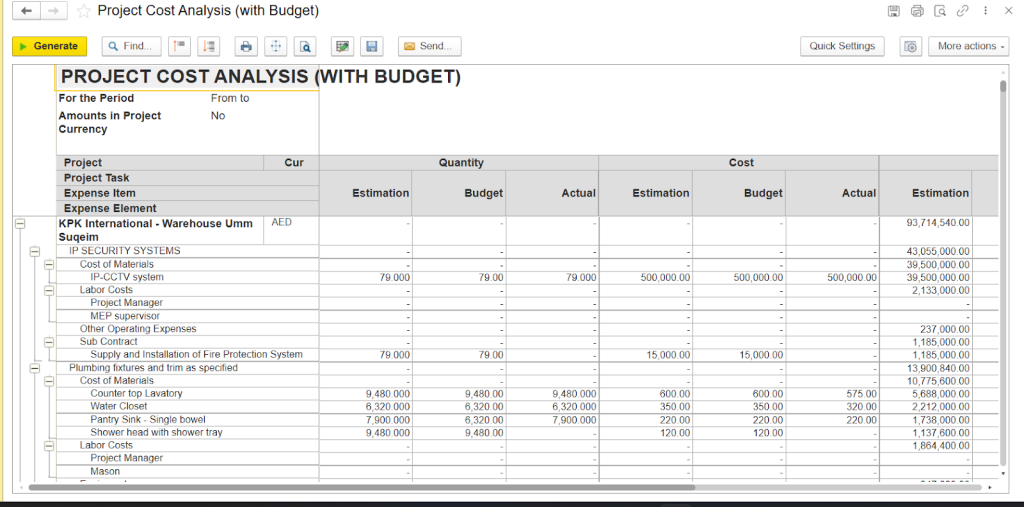

Integration With Cost Data and Budgets

FirstBit links RFQs directly with project budgets and cost codes. This means quotes are automatically aligned with approved budget lines, reducing the risk of overspending or misallocating funds.

Project cost analysis in FirstBit ERP

Automated Supplier Communication

Instead of manually emailing vendors, FirstBit ERP allows contractors to send structured RFQs directly from the system. Suppliers respond through the same platform, ensuring consistency and reducing the back-and-forth that often delays procurement.

Real-Time Comparison of Quotes

Quotes received from multiple suppliers can be viewed side by side in real-time. Project managers can quickly compare pricing, delivery terms, and specifications without having to re-enter data, which reduces manual errors.

Cloud Access and Mobility

Through its cloud-based platform and mobile app, FirstBit ensures that procurement teams can manage RFQs from the office or on-site. This flexibility keeps processes moving even when teams are distributed, and it allows managers to approve or review quotes without delay.

By consolidating RFQs, budgets, and supplier communications into one platform, FirstBit ERP removes the inefficiencies that typically slow down procurement. Contractors gain visibility, suppliers provide clearer quotes, and project managers make faster, data-driven decisions. The result is a standardized process that not only improves accuracy but also ensures procurement contributes directly to overall project success.

Conclusion

Securing accurate and competitive supplier quotes is not just about lowering costs—it’s about making procurement smarter, faster, and more reliable. With structured RFQs and clear evaluation practices, construction companies can avoid disputes, strengthen supplier relationships, and keep projects financially stable. Tools like FirstBit ERP make this process seamless by connecting every step of data, communication, and decision-making into a single platform.

By embracing a disciplined approach supported by the right technology, construction firms can turn supplier quotes from a routine task into a strategic advantage that drives both efficiency and profitability.

Build reliable partnerships with suppliers

Request a demo

FAQ

What is the difference between an RFQ and a tender?

An RFQ is used to request specific price quotes for well-defined materials or services, while a tender usually involves a more formal, competitive bidding process covering broader project requirements.

Can small construction firms benefit from using RFQs?

Yes. Even smaller firms can use RFQs to compare supplier pricing, reduce costs, and ensure transparency when sourcing materials or subcontractors.

How many suppliers should be invited to an RFQ?

Ideally, three to five qualified suppliers. This ensures competitive pricing without overwhelming the evaluation process.

Are digital RFQ tools better than manual methods?

Yes. Digital tools or ERP systems streamline communication, track responses, and reduce errors compared to spreadsheets and emails, saving significant time.

How often should RFQ templates be updated?

Templates should be reviewed at least once a year or sooner if there are changes in compliance standards, contract terms, or procurement policies.

Umme Aimon Shabbir

Editor at First Bit

Aimon brings a deep understanding of the modern construction business to her articles by providing practical content.