Construction procurement determines more than what gets bought; it dictates how your project unfolds. Pick the right method, and you align early design choices with execution, avoid costly rework, and maintain momentum. Select the wrong one, and even minor changes can become time bombs for your budget and schedule.

For 2026, that matters even more. According to McKinsey, modular construction, driven by early planning and streamlined procurement, can be 20–50% faster and deliver significant cost savings[?].

Understanding the link between procurement methods in construction and project outcomes is no longer optional; it’s essential. In this guide, you’ll learn how to match procurement routes with your project goals, why early planning and stakeholder cohesion matter, and how to build a

procurement strategy that keeps projects on time and budget.

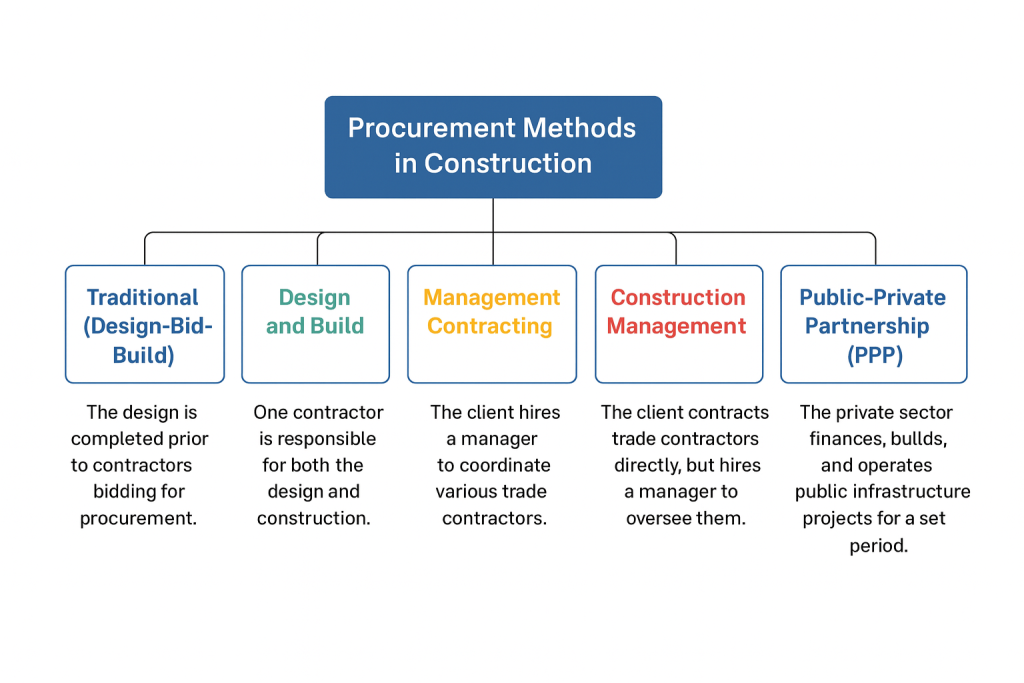

What Are Procurement Methods in Construction

In construction, procurement methods refer to the structured approaches used to acquire the services, materials, and expertise necessary to complete a project. They define how responsibilities, risks, and control are shared among the client, contractor, and other stakeholders throughout the project’s entire lifecycle, from its inception to its completion.

The right procurement method is not chosen at random; it is selected based on a clear understanding of your project’s goals and four key considerations:

- Cost. Is the objective to secure the lowest initial bid, or to achieve better long-term value through quality and efficiency?

- Time. Does the project require the shortest possible delivery schedule, or can timelines be adjusted for a more methodical approach?

- Risk. Will the client assume the majority of risk, or will it be transferred to the contractor or shared across parties?

- Control. How much oversight and involvement will the client maintain throughout the design and construction phases?

Each procurement method allocates these factors differently. For example, in some approaches, the client manages separate contracts for design and construction; in others, a single entity handles everything from concept to completion. The choice impacts not only how quickly a project progresses, but also how disputes are resolved, how costs are managed, and how adaptable the project is to change.

Importance of Early Planning and Stakeholder Alignment

Choosing the right procurement method is only half the equation. Even the most well-suited approach can fail if early planning and stakeholder alignment are overlooked.

Early planning ensures that key project parameters, including scope, budget, schedule, quality standards, and risk allocation, are agreed upon before the tendering or contracting process begins. It sets a clear baseline, making it easier to select a procurement route that fits the project’s realities.

Equally important is stakeholder alignment. Every party involved, clients, designers, contractors, consultants, and suppliers, needs to be on the same page from day one. Without this shared understanding, procurement decisions can become disconnected from actual project needs, leading to disputes, design changes, and timeline overruns.

Key benefits of strong early planning and alignment include:

-

All parties work towards the same goals, avoiding conflicting priorities during the project.

-

Potential issues like material shortages, design errors, or regulatory delays are identified early and assigned to the party best equipped to manage them.

-

Defined roles and authority levels prevent bottlenecks when approvals are needed quickly.

-

Involving contractors early allows them to suggest value engineering opportunities, optimize workflows, and provide accurate cost and time estimates.

When early planning and alignment are neglected, procurement tends to focus on short-term cost savings rather than overall value, which often leads to higher expenses and delays later in the project lifecycle. In contrast, projects that invest time in the pre-procurement phase typically experience smoother execution and better outcomes.

Types of Procurement Methods in Construction

Types of procurement methods in construction

Choosing the right procurement method sets the tone for the entire project. Each approach defines how responsibilities are split, how risks are shared, and how decisions are made from design through completion. Below is a detailed breakdown of the most common methods used in construction, with their respective advantages and disadvantages.

Traditional Procurement Method (Design–Bid–Build)

Design–Bid–Build (DBB) delivers the project in three sequential stages: complete the design, tender the works, and then construct. The client first appoints the design team to produce full drawings, specifications, and schedules.

Only after a design freeze does the client invite competitive bids. The successful contractor delivers the works strictly against the issued documents, with the design team retained to administer the contract and certify payments/variations.

This route is familiar to most owners and public bodies because it is straightforward to govern and easy to audit. Its strength is clarity, roles are distinct, pricing is comparable, and changes are managed through formal instructions. Its weakness is inflexibility, because design and construction are separate, any change after tender must pass through a contractual variation process, which can add time and cost.

Projects with stable scope, high documentation quality, and a client who wants tight control over design are the best fit.

Advantages:

-

The clear separation of responsibilities between designer and contractor simplifies accountability and contract administration for the client.

-

Competitive tendering against a completed design enables like-for-like bid comparison and can help secure favorable pricing.

-

A fully developed design at tender provides strong cost certainty at the point of award and reduces ambiguity on scope.

Disadvantages:

-

The sequential nature of the process typically lengthens the overall timeline because construction cannot start until the design is complete.

-

Limited contractor input during design reduces opportunities for buildability improvements, program efficiencies, and value engineering.

-

Design gaps discovered post-award are resolved through variations, which can trigger delay, disruption, and claims.

Design and Build Procurement Method

Design and Build (D&B) places single-point responsibility for both design and construction with one entity (the D&B contractor). The client issues an employer’s requirement/brief (with a concept or performance specification), and the D&B contractor completes the detailed design while mobilizing construction.

Because design and construction overlap, site work can start sooner, and design decisions are made with direct input from the delivery team. This integration reduces interface risk and the “who’s responsible?” disputes that can occur in separated models.

D&B suits projects that need speed, program certainty, and coordinated accountability. It also works well where the client wants a performance-based outcome (e.g., energy targets, throughput, lifecycle performance) rather than prescriptive detailing. The trade-off is that the client must lock down functional requirements early and should manage design quality through robust technical briefs, review gates, and compliance checking.

Design-build is projected to account for up to 47% of U.S. construction spending in assessed segments by 2026 (over $400B), reflecting its growing adoption for schedule and integration benefits[?].

Advantages:

-

Single-point responsibility for design and construction reduces interface risk and simplifies communication for the client.

-

Overlapping design and construction enables an earlier site start and can compress the overall program significantly.

-

Contractor-led detailing often improves constructability, logistics planning, and cost control through supplier integration.

Disadvantages:

-

Client influence over detailed design is lower after award, so quality must be safeguarded via clear employer’s requirements and staged reviews.

-

Proposal comparability at tender can be challenging because solutions may differ in scope, methodology, or specification.

-

If the contractor prioritizes the lowest capital cost over long-term value, there is a risk of quality dilution without strong technical standards and acceptance criteria.

Management Contracting Procurement Method

In Management Contracting, the client appoints a management contractor early in the project to manage and coordinate trade contractors who carry out the works. The design progresses in packages, and each package is tendered and let under separate trade contracts with the management contractor. This allows early works packages (e.g., demolition, foundations) to start before the full design is complete, speeding up delivery.

This route works best for complex or large-scale projects where early site access, flexibility, and specialist trade input are critical. The client retains direct contractual relationships with the management contractor only (not individual trade contractors), but bears most of the cost risk because trade contract prices are not all known at the outset.

Advantages:

-

Early appointment of the management contractor enables fast-tracking of construction activities while design packages are still being developed.

-

Specialist trade contractors are directly involved in design development, improving buildability, and innovation in methods and materials.

-

The structure allows flexibility to adjust the scope mid-project without halting progress on other packages.

Disadvantages:

-

Final project cost is uncertain at the outset, as many packages are tendered after work has begun.

-

The client bears more financial risk for cost escalation in trade packages compared with lump-sum methods.

-

Requires strong coordination between design teams, the management contractor, and trades to avoid delays or interface conflicts

Construction Management Procurement Method

Construction Management (CM) is similar to Management Contracting but with a key difference: the client directly contracts with all trade contractors. The construction manager acts as an agent, managing procurement, coordination, and site logistics, but does not carry the cost risk for trade packages.

This gives the client more control over scope, quality, and appointment of trades, but also places greater administrative and contractual responsibility on them.

CM is often chosen for fast-track projects or in markets where the client has the expertise and resources to actively manage multiple contracts. Because work packages are procured as needed, the client can benefit from competitive pricing and flexibility to change scope mid-project.

Advantages:

-

Direct contracting with trades can give the client more control over contractor selection, quality standards, and commercial terms.

-

Fast-tracking is possible by starting early work before the full design is complete.

-

Competitive procurement of individual packages may deliver better market rates.

Disadvantages:

-

Requires the client to have significant procurement and contract administration capability.

-

An increased number of contracts means higher management complexity and risk of disputes between trade contractors.

-

Limited cost certainty at the start compared to fixed-price lump-sum methods.

Joint Venture Procurement Method

A Joint Venture (JV) brings two or more organizations together, typically contractors, developers, financiers, or specialist firms, to deliver a single project under a shared governance and commercial framework. The JV can be incorporated (a new special-purpose company) or contractual (an unincorporated alliance).

Partners pool resources, combine balance sheet strength, and coordinate design, delivery, and commercial decisions through a JV agreement that sets out equity shares, decision rights, risk allocation, dispute resolution, and exit provisions.

JVs are well-suited to large, complex, or high-risk projects, to bids requiring local capability or licenses, or where complementary expertise (e.g., tunneling + MEP + operations) is essential to win and deliver the work.

Advantages:

-

A joint venture allows partners to combine complementary capabilities, local knowledge, and supply chains so the team meets prequalification, licensing, and bonding requirements that a single firm might not satisfy.

-

Sharing financial and performance risk across partners enables the pursuit of larger or more complex projects while maintaining prudent exposure for each organization.

-

The combined procurement volume and subcontractor relationships can improve pricing leverage and access to scarce labor, equipment, and long-lead materials.

-

Structured collaboration promotes knowledge transfer and innovation, accelerating problem-solving on design integration, logistics, and buildability.

Disadvantages:

-

Shared governance adds complexity; without clear voting thresholds and deadlock mechanisms, decision-making can slow, and critical actions can stall.

-

Strategic misalignment and cultural differences between partner organizations can create inconsistent processes, duplicate effort, and quality or safety friction on-site.

-

Profit is diluted across partners, and cost allocation (for prelims, overheads, and change management) can become a source of dispute if not defined precisely.

-

In some jurisdictions and contract forms, joint and several liability means one partner may be exposed to the other’s performance failures, increasing contingent risk.

Private Financing Procurement Method

Private Financing is commonly delivered as Public–Private Partnerships (PPP) or Private Finance Initiative (PFI) bundles, design, build, finance, and often operate/maintain into a single long-term contract with a private consortium. The public client specifies performance outcomes, and the private partner finances delivery and recoups investment over the concession term through availability payments or user-fee revenue.

This route suits capital-intensive infrastructure (roads, hospitals, schools, utilities) where upfront public funding is constrained and where long-term performance incentives can improve reliability.

Typical PPP concessions run 20–30 years[?].

These durations align payments with asset life, link contractor incentives to whole-life performance, and create a framework for structured maintenance rather than short-term fixes.

In the UK, the National Audit Office reported most PFI construction was delivered on time and at expected cost (24% late; 22% over cost), a marked improvement over earlier conventional government projects, where about 70% were delivered late[?].

The delivery performance reflects how risk transfer and milestone-based payments tighten schedule discipline. Results can vary by sector and contract quality, so rigorous preparation and monitoring remain essential.

Advantages:

-

This model shifts a significant share of financing and construction risk to the private partner, reducing the public client’s immediate budget exposure.

-

The integration of design, construction, and long-term O&M aligns incentives toward whole-life value, not just the lowest first cost.

-

The contract structure rewards predictable delivery and asset availability, which can improve service reliability over the life of the asset.

Disadvantages:

-

The contracts are complex and time-consuming to negotiate, increasing transaction costs and lead times before site start.

-

The total lifecycle cost can exceed direct public procurement if financing terms or risk pricing are unfavorable.

-

The long concession period can limit flexibility to adapt to changed needs or technologies without formal variations.

Reduce costs and avoid shortages

Optimize procurement with FirstBit

Request a demo

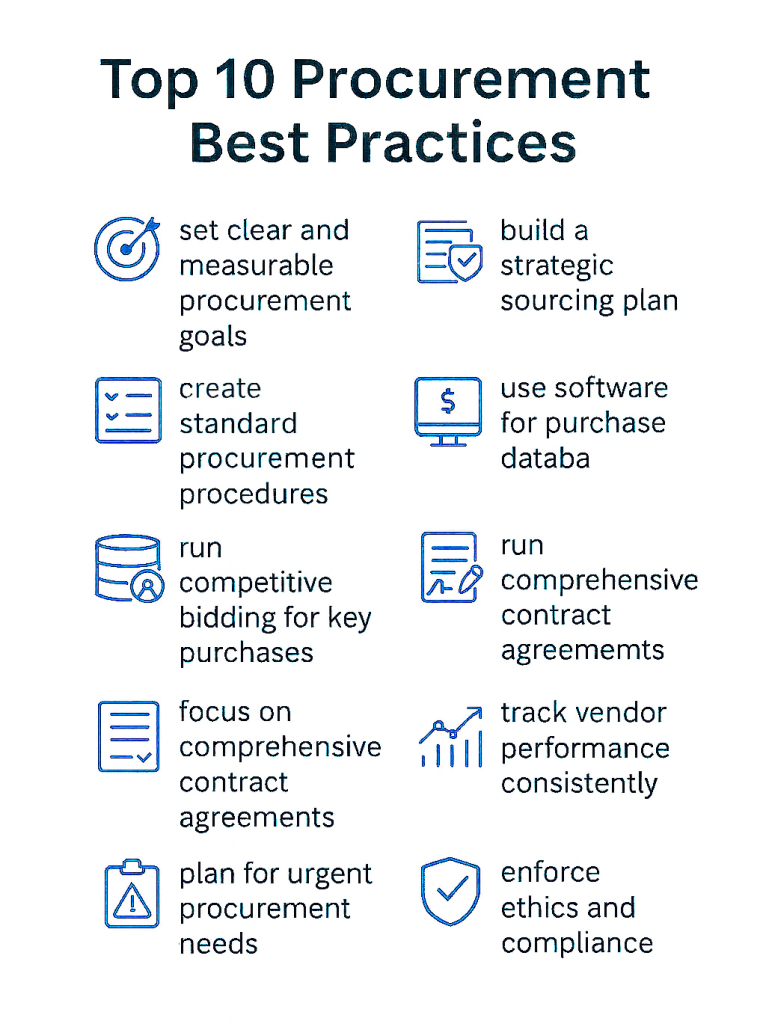

Procurement Best Practices

Effective procurement in construction is more than just buying materials; it’s about making smart, timely, and strategic decisions that keep projects on budget and schedule. The following best practices focus on helping construction teams in 2026 navigate market volatility, manage supplier relationships, and align every purchase with broader project objectives.

Top 10 procurement best practices

1. Set Clear and Measurable Procurement Goals

Rather than setting broad, non-specific objectives, define procurement goals in terms of measurable outcomes that directly impact your project and business performance. For example:

These clear targets guide both strategy and performance measurement. Your procurement team knows what success looks like, and can use real data to track improvements and course-correct as needed.

2. Build a Strategic Sourcing Plan

Effective sourcing begins with data-led planning:

-

Perform a spend analysis to identify where money goes and which categories account for the largest budget share.

-

Map the supplier landscape, understand which suppliers can meet your quality, sustainability, and delivery requirements.

-

Schedule sourcing events early, especially for long-lead items such as MEP components or façade systems, aligning them with project milestones to prevent procurement delays.

This proactive approach avoids emergency buying, prevents inflated last-minute pricing, and ensures supply chain resilience.

3. Create Standard Procurement Procedures

Clear, written procedures reduce confusion and ensure compliance:

-

Define who has authority to approve purchases (e.g., by value thresholds).

-

Outline required documentation (e.g., procurement plan, approval forms, contract templates).

-

Include risk protocols, for example, steps to follow if a supplier becomes non-compliant or fails inspections.

Standard workflows mean that whether your procurement manager is in Dubai or Karachi, they follow the same steps, improving oversight and reducing errors or policy gaps.

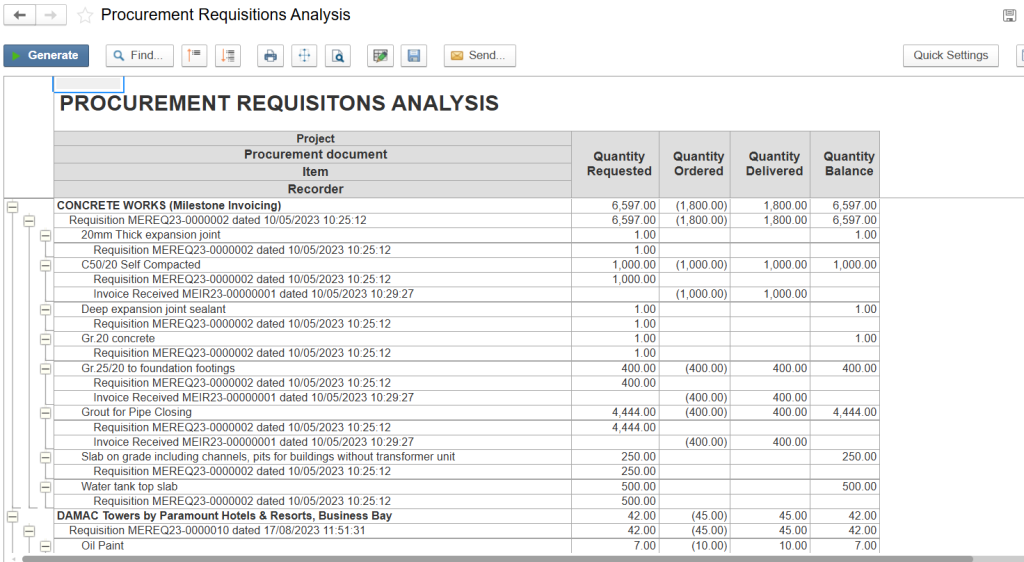

4. Use Software for Purchase Orders

Manual PO tracking can cause confusion, lost orders, and approval bottlenecks. Procurement software centralizes visibility:

-

Generate and send POs digitally, with clear links to BOQ items or tender packages.

-

Automate approval workflows so managers get alerts in real time.

-

Track PO status from issue to delivery and incorporate budget integration to highlight cost variances.

For example,

FirstBit’s procurement module enables full purchase order control within the ERP system, linking procurement directly to budgets, deliveries, and cost allocation.

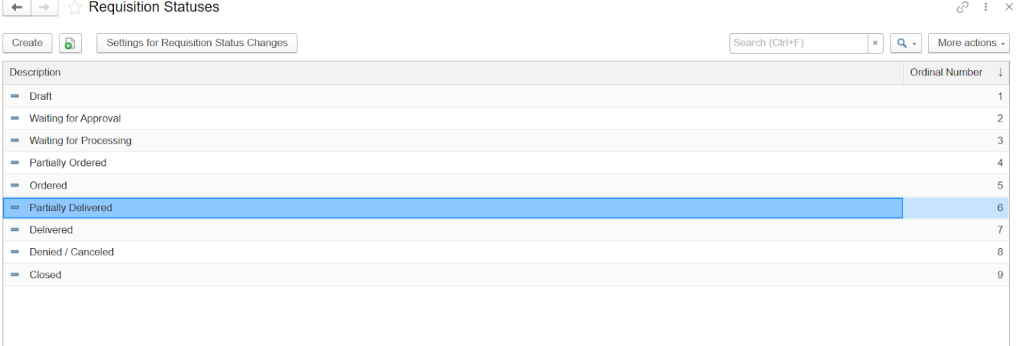

Procurement Requisition Analysis in FirstBit

5. Maintain a Central Supplier Database

Keep a single source of truth for supplier information that includes:

-

Contract terms, renewal dates, performance history (on-time delivery, quality, dispute records)

-

Compliance documentation, such as certifications or financial stability checks

-

Communication records, especially for key suppliers

Such a database accelerates supplier evaluation, ensures consistency across projects, and helps you hold suppliers accountable. Without it, you risk repeating past mistakes or losing oversight.

6. Run Competitive Bidding for Key Purchases

Competitive procurement ensures transparency and drives value. Steps include:

-

Draft clear, objective

RFQ or

RFP documentation outlining scope, evaluation criteria, and submission timelines.

-

Evaluate offers consistently, score responses on price, capability, schedule, and past performance.

-

Document the decision-making rationale to safeguard against disputes, audits, or governance challenges.

This method protects project integrity and ensures that major spend areas are negotiated fairly and strategically.

7. Focus on Comprehensive Contract Agreements

Successful procurement isn’t just about negotiating the lowest price; it’s about securing agreements that protect project delivery and ensure quality. Your contracts should include:

-

Clear service-level commitments, including delivery timelines and performance metrics.

-

Warranties for workmanship and materials to safeguard against defects. Continuous improvement clauses, so suppliers are motivated to enhance performance over time.

Contracts should balance risk and reward fairly, ensuring that both parties have aligned incentives to meet project goals. This reduces disputes, enhances supplier relationships, and ensures better long-term outcomes.

8. Track Vendor Performance Consistently

A supplier who performed well last year may not maintain the same standards today. Consistent monitoring keeps performance in check. Use measurable indicators such as:

Hold quarterly or semi-annual performance reviews and take action for underperformance, whether that means implementing training, renegotiating terms, or switching vendors. By tracking vendor performance methodically, you can catch issues early, maintain quality, and strengthen long-term supplier relationships.

9. Plan for Urgent Procurement Needs

Construction projects often face unforeseen requirements, last-minute client changes, sudden supplier failures, or weather delays. Prepare for such situations by:

-

Maintaining a pre-approved list of vetted suppliers who can respond quickly.

-

Setting aside contingency budgets for emergency buys.

-

Having expedited internal approval procedures for urgent POs.

This ensures projects can adapt without delays or excessive costs, even when procurement timelines are compressed.

10. Enforce Ethics and Compliance

Ethical procurement safeguards both your reputation and legal standing. Core measures include:

-

Clear policies on conflict of interest and gift acceptance.

-

Fair treatment of all suppliers, ensuring equal access to bidding opportunities.

-

Mandatory ethics training for procurement staff.

-

Ongoing compliance monitoring to detect and address violations quickly.

In the long run, an ethical approach not only reduces legal risks but also builds trust with stakeholders and suppliers, both of which are critical for sustained success.

While these best practices create a strong procurement foundation, their real impact depends on how well you track and measure them. That’s where benchmarks come in, offering clear, objective indicators of success and helping you pinpoint where to improve. By combining actionable best practices with performance benchmarks, you turn procurement from a reactive function into a strategic advantage.

How To Use Procurement Best Practices Benchmarks

Applying procurement best practices is only effective if you can measure their real-world impact. Benchmarks provide clear, data-driven insights into what’s working, what’s lagging, and where adjustments are needed. By tracking the right indicators, you can continuously refine your procurement strategy and ensure it delivers both immediate and long-term value.

1. Track Cost Reductions

Savings should be evaluated in the context of total value delivered, not just one-time discounts. Track actual cost reductions over time, considering both direct savings (like negotiated lower prices) and indirect gains (such as reduced rework or faster delivery that avoids delay penalties). Review these savings on a project-by-project basis to identify which procurement strategies consistently yield the highest returns.

Tip: Create a simple cost-tracking dashboard in your ERP that logs the original estimate, final purchase price, and variance for every major purchase. This helps visualize where your team is winning and where more negotiation leverage is needed.

2. Measure Procurement Cycle Time

Delays in procurement often lead to costly project overruns. Monitor the time taken from requisition to purchase order, and from PO issuance to delivery. Segment the data, comparing routine purchases with complex or long-lead orders to reveal bottlenecks. If specific categories are consistently slower, address them by prequalifying suppliers, simplifying approval steps, or scheduling orders earlier in the project timeline.

Tip: Use automated PO tracking tools that timestamp every stage in the process, making it easier to spot delays and speed up approvals.

3. Set Supplier Performance Targets

Supplier relationships perform best when expectations are explicit. Define measurable targets for on-time delivery, defect rates, and responsiveness. Document these KPIs in supplier agreements and enforce stricter requirements for critical or high-value suppliers. Regular reviews against these targets help maintain accountability and ensure that suppliers consistently meet your quality and scheduling needs.

Tip: Introduce a quarterly “supplier scorecard” that is shared openly with vendors. It fosters transparency and motivates them to maintain or improve performance.

4. Monitor Procurement Team Efficiency

A high-functioning procurement team balances speed with strategic value. Track output per team member or transaction, and assess how much time is being spent on manual tasks versus activities like supplier negotiations or contract optimization. Leveraging automation can reduce repetitive work, allowing the team to focus on decisions that drive greater cost savings and efficiency.

Tip: Review your weekly workloads to ensure high-value activities are receiving sufficient attention. If not, reassign or automate repetitive tasks.

5. Track Policy Compliance

Policies only work if they are consistently followed. Measure adherence by tracking how often purchases align with approved suppliers, approved budgets, and established approval processes.

Keep an eye out for maverick spend purchases made outside the defined procurement framework, which can increase costs, create quality inconsistencies, and undermine supplier relationships. Implement corrective actions quickly through training, policy reinforcement, or tighter controls.

Tip: Run monthly compliance reports in your ERP to identify policy breaches and address them before they become habitual.

Build reliable partnerships with suppliers

Request a demo

Streamlining Procurement Process with FirstBit ERP

In construction, procurement moves fast, and mistakes move even faster. Delays in approvals, missing supplier data, or unclear purchase orders can throw an entire schedule off track. FirstBit ERP is designed to prevent that, giving procurement teams real-time visibility, structured workflows, and complete control from requisition to delivery.

Real-time Requisitions with Automated Approvals

Teams can raise requisitions on-site and get them approved without chasing signatures. Automated workflows route requests to the right managers instantly, with a clear audit trail to track every decision. This keeps projects moving without bottlenecks.

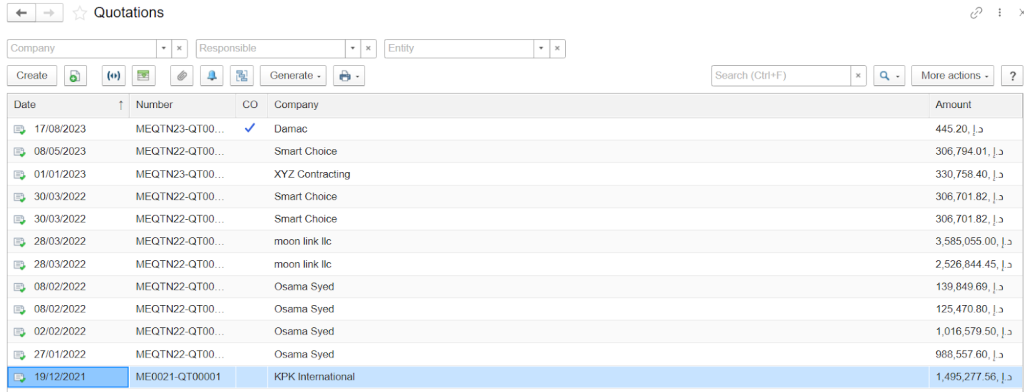

Clear, Side-by-Side Supplier Comparisons

When multiple quotes are on the table, FirstBit displays them in a single view, making it simple to weigh price, quality, and delivery timelines together. This ensures selection decisions are both competitive and well-informed.

Quotations from vendors in FirstBit ERP

Live Tracking of Orders and Stock

From the moment a purchase order is issued, its progress is visible: what’s ordered, what’s shipped, what’s received, and even what’s still in transit. This real-time tracking helps avoid costly shortages or over-ordering.

Order tracking in FirstBit ERP

Integrated PO reporting for budget control

Every PO links directly to the

project budget, updating reports automatically. Managers can see actual spending against planned allocations and make adjustments before overruns occur.

Because procurement doesn’t work in isolation, FirstBit connects with estimating,

BOQ uploads, subcontractor tracking, and approval processes, ensuring purchasing decisions align with the bigger project picture.

Conclusion

Strong procurement is rarely the loudest part of a project, but it’s often the reason deadlines are met, costs are controlled, and quality stays consistent. The best practices and benchmarks outlined here give teams the framework to make procurement a driver of project success rather than a reactive function.

When that framework is paired with a purpose-built system like FirstBit ERP, the benefits compound, streamlined processes, fewer delays, and complete visibility from request to delivery. This combination turns procurement from a potential risk into one of the project’s strongest competitive advantages.

Align every purchase with project goals

Track supplier performance and control costs

Request a demo

FAQ

What are the most common procurement methods in construction?

The most common methods include: traditional (design-bid-build), design and build, construction management, management contracting, Public-Private Partnerships (PPP), joint venture.

Each has its advantages and drawbacks depending on project complexity, budget, risk-sharing, and timeline.

What are the key procurement best practices for construction companies?

Some proven best practices are: developing a clear procurement strategy aligned with project objectives, standardizing RFQ/RFP templates, maintaining long-term supplier relationships, using ERP systems to automate processes, monitoring supplier performance, and ensuring compliance with regulations and contracts.

How do I choose the right procurement strategy for my construction project?

The choice depends on project size and complexity, level of design development, client’s risk tolerance, budget and timeline constraints, and the procurement team’s expertise.

What role does technology play in modern construction procurement?

Technology helps automate repetitive tasks, reduces manual errors, improves transparency, and speeds up procurement decisions. Digital procurement tools, such as ERP systems, allow companies to centralize data, monitor supplier performance, and enhance collaboration across teams.

Umme Aimon Shabbir

Editor at First Bit

Aimon brings a deep understanding of the modern construction business to her articles by providing practical content.