Construction projects often fail not due to poor craftsmanship but because logistics are poorly managed — materials arrive late, equipment sits unused, and crews lose time navigating a disorderly site.

When logistics are poorly planned, projects slow down, costs rise, and profitability drops. That’s why contractors need a practical way to coordinate site deliveries, workspace layout, and workflow without constant firefighting.

This article provides a simple, step‑by‑step guide to construction logistics planning. You’ll see why it matters, how to build a working plan from day one, and how to use logistics to keep your schedules tight, your costs under control, and your site safe and efficient — whether you manage small renovations or large commercial builds.

What is Logistics Construction Planning

Logistics construction planning is the process of organizing how materials, equipment, people, and information move through a construction project from start to finish. It defines how resources are delivered, stored, and accessed on-site to support daily work without interruption.

Unlike general construction planning, which focuses on what needs to be built and when, logistics planning focuses on how everything needed to build it will arrive, be handled, and flow across the site. This includes delivery schedules, site access points, traffic control routes, material storage zones, and even how waste will be removed.

For example, an urban project with limited road access may need night-time deliveries and staged unloading to avoid blocking public traffic. Without a plan, late deliveries can stall crews, trigger delays, and even cause fines for road obstruction. A solid logistics plan avoids these issues, keeping materials on schedule and nearby streets safe and clear..

A good logistics plan acts as a roadmap for smooth operations. It prevents resources from piling up in the wrong places, ensures crews have the tools and materials they need at the right time, and keeps the site organized enough to stay safe and efficient.

Why Do You Need a Construction Logistics Plan

A construction logistics plan impacts multiple aspects of project delivery, starting with how work flows from the very first day on site.

Improve Workflow from Day One

Delays on a construction site often start small — like a missing material shipment or equipment parked in the wrong place — but quickly escalate into costly downtime and rework. A strong logistics plan helps you anticipate these risks and manage them before they impact the schedule.

By

mastering material management, you reduce idle time and prevent last‑minute adjustments. For example, if a delivery truck can’t reach the site because the access route isn’t cleared, your team might lose half a day waiting. A clear logistics plan maps these details in advance so you can keep the project moving and avoid surprise expenses.

Treating logistics as a cost-control tool rather than just a delivery schedule helps protect both your timeline and your budget.

Create a Safe Worksite

A busy construction site is full of moving equipment, delivery vehicles, and workers on tight schedules, all potential safety risks if not managed properly. A logistics plan helps you control how materials, vehicles, and people move across the site, reducing the chance of accidents.

For example, defining clear routes for delivery trucks and separating them from pedestrian walkways minimizes collision risks. Specifying storage areas for heavy materials keeps them from cluttering work zones or blocking emergency exits. When you integrate traffic control measures and safety protocols into your logistics planning, you reduce hazards and keep work progressing safely.

Achieve peak productivity on site

Manage teams, equipment, and materials in FirstBit

Request a demo

Construction Site Logistics Plan in 10 Steps

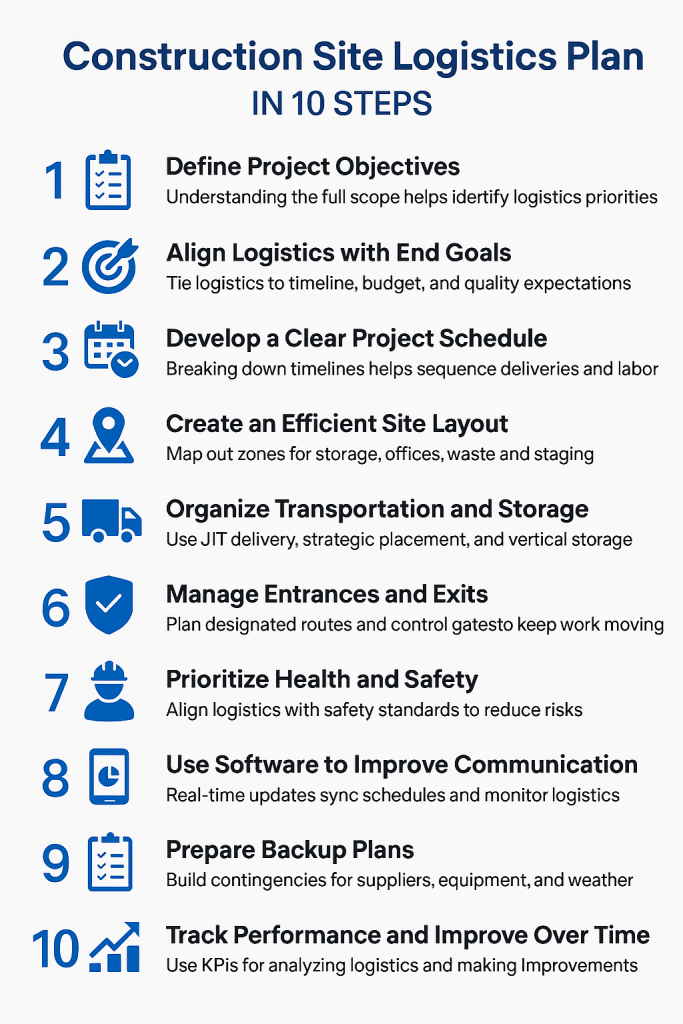

A well-planned logistics strategy keeps materials, people, and equipment moving efficiently on-site, which reduces delays and improves safety. The following 10 steps outline how you can build a practical logistics plan for your projects.

Construction site logistics plan in 10 steps

Step 1: Define Project Objectives

Define exactly what the project needs to deliver. A clear scope helps you identify logistics priorities early, such as restricted delivery hours, limited site access, or time‑sensitive milestones.

For instance, a downtown project might require nighttime deliveries to avoid congestion, while a remote site could need planning for long-distance material transport. With success criteria like on-time completion and a zero-incident safety record, defined from the start, every logistics decision can be tailored to meet them. A logistics plan focused on safety performance will prioritize clear site access and off-hours deliveries, while a plan focused on the schedule will ensure materials arrive exactly when needed to prevent delays.

Step 2: Align Logistics with End Goals

Once your objectives are clear, link every logistics decision to the outcomes you want. This means you need to evaluate how material deliveries,

equipment management, and workforce access support project deadlines, quality benchmarks, and budget constraints.

For example, scheduling deliveries around major structural milestones ensures critical materials arrive when crews need them, preventing idle time. Aligning logistics with project deliverables also helps you avoid unnecessary movements that waste time or create safety risks.

Tying logistics planning directly to project goals helps eliminate wasted movements and ensures on-site activities contribute to deadlines and budgets.

Step 3: Develop a Clear Project Schedule

A strong logistics plan relies on a clear and realistic schedule.

Break down the project into phases, identifying when each trade will be on-site and what materials they need at each stage. This lets you sequence deliveries, schedule equipment use, and assign labor without workflow clashes.

Include buffers and milestones to accommodate unexpected changes such as weather delays, inspections, or design adjustments. For example, planning extra time around concrete curing or utility installations can prevent cascading delays later in the project.

When your logistics plan is built on a detailed schedule, you can coordinate resources with confidence and adapt quickly when conditions change.

Step 4: Create an Efficient Site Layout

How you organize space on a job site directly affects productivity and safety. Map out where materials, equipment, offices, and waste collection points will be located before work begins. A well‑designed layout reduces unnecessary travel, prevents storage areas from blocking access routes, and keeps critical pathways clear for emergency use.

Consider how the site will change over time. Early stages may require large areas for structural materials, while later phases may need more room for interior finishes and staging. Designing a flexible layout that evolves with each phase keeps operations efficient from start to finish.

Step 5: Organize Transportation and Storage

Managing material delivery and storage is central to efficient logistics.

Transportation can make up 10–20% of total project costs, so planning it well has a direct impact on profitability[?].

Use just‑in‑time (JIT) deliveries to reduce clutter and cut theft or damage risks. Store frequently used materials near active work zones, keeping secondary areas for less common items.

On tight or urban sites, vertical racks and scheduled delivery windows help keep routes clear. Coordinating timing with suppliers prevents bottlenecks and keeps crews working instead of waiting.

Step 6: Manage Entrances and Exits for Better Site Access

Controlled access points are essential for keeping your site organized and safe. Plan where vehicles, workers, and visitors will enter and exit, and designate separate routes for heavy equipment and foot traffic to reduce accident risks.

For projects in urban areas or sites with limited access, staggered delivery times and clearly marked traffic flows help prevent congestion. Emergency access routes should remain open at all times, and security checkpoints or sign‑in systems can be added to monitor site activity.

Managing entrances and exits well improves the flow of people and materials while supporting site security and safety compliance.

Step 7: Prioritize Health and Safety

Every movement on a construction site carries risk, from trucks reversing in tight spaces to workers handling heavy materials. Incorporating safety into your logistics plan mitigates risks and ensures compliance with local and national standards. There are three actions to take:

-

Plan safe pedestrian pathways and separate hazardous material storage zones.

-

Ensure delivery and work areas have proper lighting and visibility for both crews and drivers.

-

Link safety briefings directly to logistics changes, such as new delivery routes or temporary storage areas, so every worker knows how to move safely through the site.

Construction logistics also impact the surrounding community. They account for up to 30% of urban freight tonnage and can create congestion, safety hazards, noise, and air pollution[?].

Poorly managed logistics not only disrupt daily life but also cause costly delays and economic losses for contractors. By integrating safety measures and carefully managing traffic flows, you protect your workers, maintain project timelines, and reduce your impact on the community.

Step 8: Use Software to Improve Communication

Use digital tools to keep logistics running smoothly.

Poor coordination can waste up to one‑third of workers’ time and cut labor and equipment productivity by 30%.

An ERP system or construction management software helps by centralizing delivery schedules, workforce assignments, and equipment tracking in one place. With mobile access, site teams can update delivery logs, approve changes, and check schedules directly from the field.

Combine these tools with strategies like consolidation centers, just‑in‑time checkpoints, and third‑party logistics providers, which have already reduced logistics costs by up to 20% for some firms. The result is real‑time communication, fewer delays, and a site that keeps moving efficiently.

Step 9: Prepare Backup Plans

Even the best logistics plans can face disruptions, whether it’s a supplier delay, equipment breakdown, or unexpected weather. Preparing backup plans ensures your project can adapt quickly without major downtime.

This could mean lining up alternative suppliers, planning multiple delivery routes, or creating temporary storage options. Having predefined steps for common disruptions keeps work moving and prevents small problems from escalating into full project delays.

A strong backup strategy keeps your logistics plan resilient under changing conditions.

Step 10: Track Performance and Improve Over Time

Logistics planning doesn’t end once work begins. Monitoring how well deliveries, storage, and access routes are performing helps you spot issues early and make quick adjustments.

Use key metrics such as delivery accuracy, unloading times, and equipment idle hours to evaluate efficiency. After the project, review what worked well and where delays or safety concerns occurred. These insights make future logistics plans more accurate, cost‑effective, and easier to execute.

By tracking performance, you turn logistics planning into a continuous improvement process rather than a one‑time task.

A logistics plan is not static; it evolves as your project moves forward. Digital tools make this process easier by providing real-time visibility of schedules, deliveries, and site activity.

For example, FirstBit ERP offers mobile field updates, delivery tracking, and resource planning in one platform. Combined with these ten steps, it helps keep materials, equipment, and people moving efficiently, maintain safe site practices, and reduce costly delays. With structured planning and digital support, you can adapt faster and improve with every project.

How FirstBit Helps in Turning Planning Into Results

Even the best logistics plan only works if it’s easy to manage and keep updated as the project changes. FirstBit ERP turns those plans into daily, actionable workflows. Delivery schedules, material orders, equipment assignments, and crew allocations are stored in one platform, so you don’t waste time searching through spreadsheets or disconnected systems.

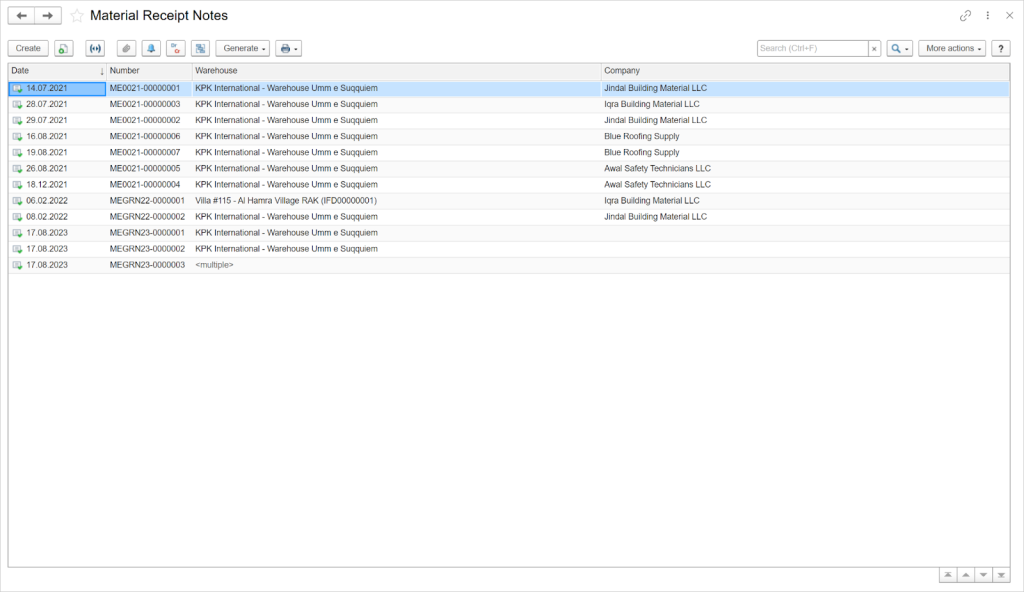

Material receipts notes in FirstBit ERP

With mobile access, teams can update delivery logs, confirm material arrivals, or approve changes right from the field, keeping information current without paperwork delays. Built-in resource and cost planning tools link logistics activities directly to budgets and project timelines, helping you see how changes in deliveries or site layouts affect the bigger picture.

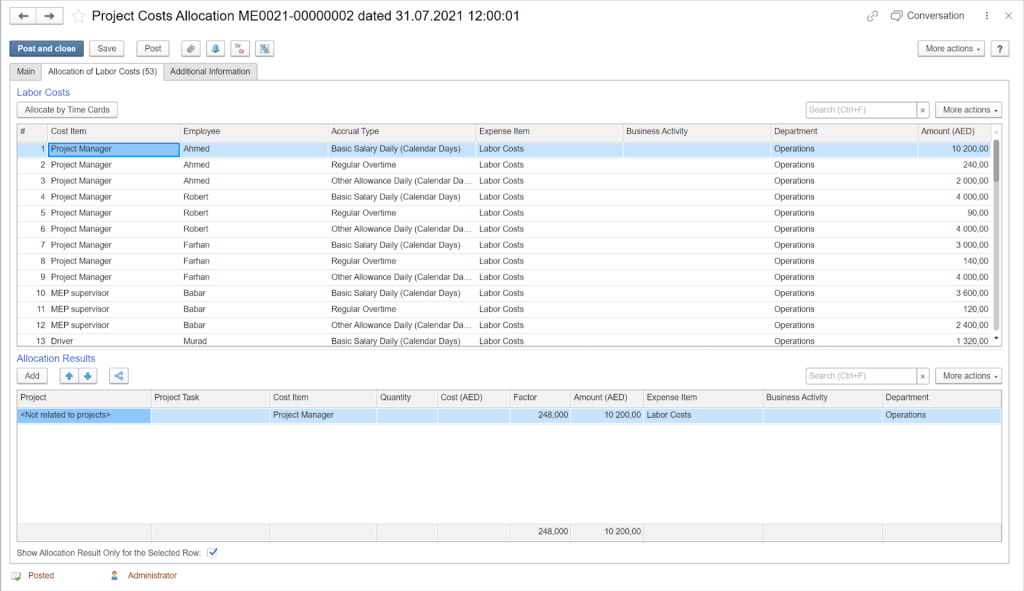

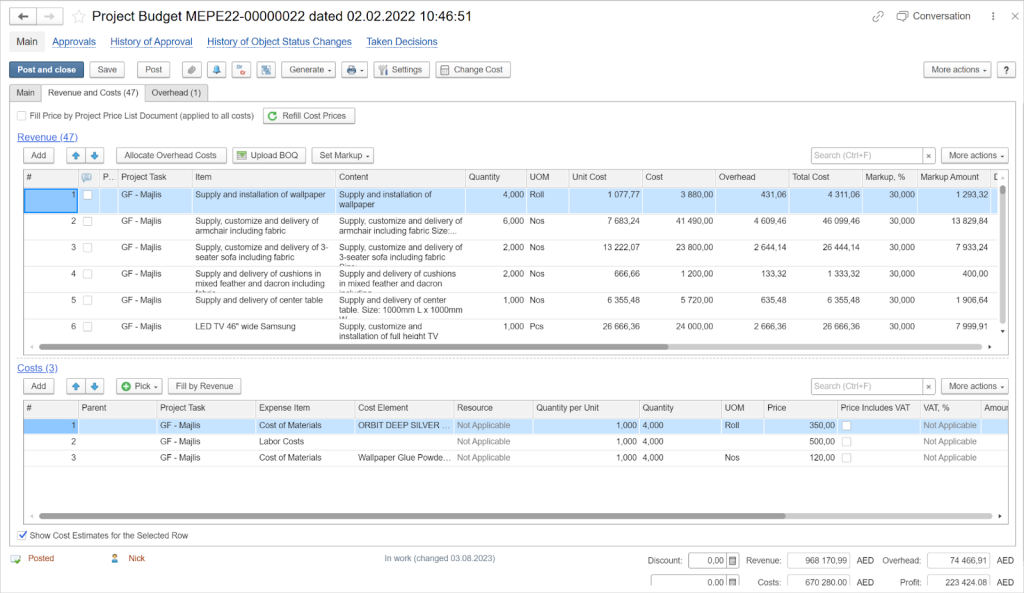

Project Budget in FirstBit ERP

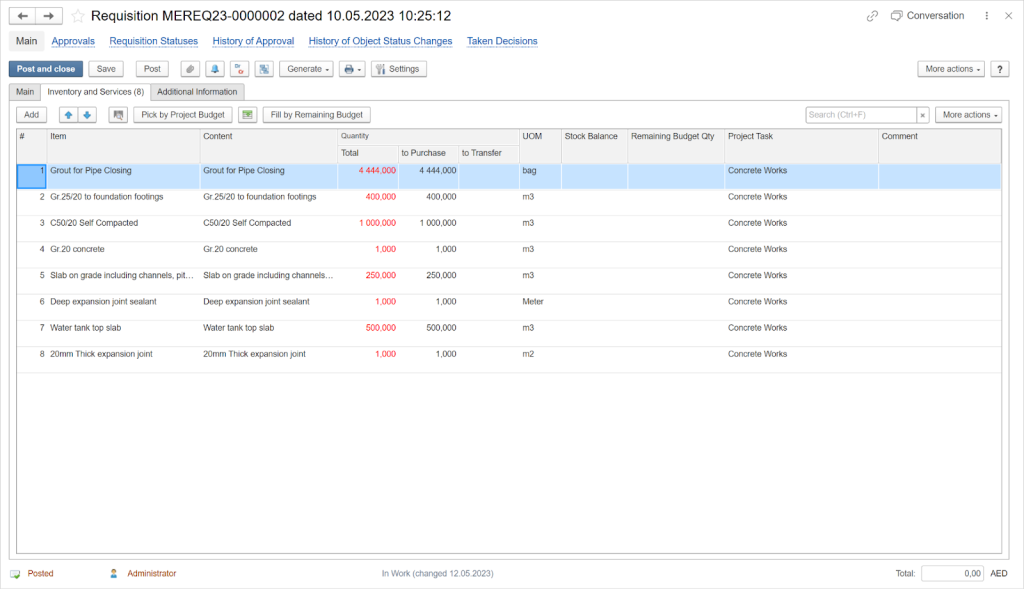

Requisition example in FirstBit ERP

This integration turns logistics planning into a living process, easy to adjust when conditions change and transparent enough for everyone involved to stay on the same page.

Stay ahead of delays

Request a demo

Final Thoughts

Construction logistics is moving beyond static plans and manual coordination. With tighter deadlines, stricter safety requirements, and increasingly complex supply chains, the ability to adjust in real time has become a competitive advantage.

Companies that treat logistics as a living process and not just an early-stage checklist are better positioned to handle disruptions, adopt sustainable practices, and deliver consistent results. As digital tools and data-driven decision-making become standard, logistics planning is evolving into a strategic function that influences cost control, risk management, and even client relationships.

For contractors, this shift is an opportunity: improving logistics isn’t just about keeping today’s project on track; it’s about building a stronger foundation for every project to come.