One wrong hire can turn a straightforward project into months of delays and spiraling costs. Choosing the right contractor can make or break a project. Even with solid plans and quality materials, one bad choice can lead to delays, cost overruns, and endless headaches. Yet finding a team that truly fits your goals, budget, and quality standards isn’t always straightforward.

This guide breaks down the key questions to ask and strategies to use when selecting contractors and suppliers, so your next project starts strong and stays on track.

Why Selection Matters More Than Ever in Construction

Selecting the right contractors and suppliers is critical for project success. From high-rise buildings to infrastructure developments, reliable partners ensure quality, timeliness, and cost efficiency.

Poor choices can lead to delays, cost overruns, or substandard work, harming your reputation and finances. A thorough selection process minimizes risks and ensures projects meet high standards.

This is not just theory — real-world failures show the cost of poor contractor selection.

Case study

This large British hospital project became a cautionary tale after the collapse of its contractor, Carillion[?]. Carillion was chosen to build the hospital under a PFI (public-private partnership) but fell into financial trouble.

By the time Carillion went bankrupt in January 2018, the hospital was only 85% complete and already delayed[?]. Work immediately halted, and an investigation revealed significant construction defects that had been hidden: the new contractor had to strip out three floors to reinforce cracked concrete beams that left the structure unsafe. The fallout was severe — the hospital’s opening was delayed by five years (from 2017 to 2022), and its cost increased from $950 million to over $1.27 billion.

Ultimately, this project serves as a stark reminder: every brick, every beam, every decision made at the outset impacts the final structure. A keen eye on the foundations, figurative or literal, can save a world of trouble down the line.

Key Criteria for Choosing the Right Contractors and Suppliers

Choosing contractors and suppliers requires evaluating several key criteria to ensure they align with your project’s needs. Below are the essential factors to consider, along with how to assess them:

1. Relevant Experience and Track Record

A supplier's reputation tells you everything you need to know about their service quality and reliability. By checking online reviews and speaking with past clients, you'll get a clear picture of their performance.

Look for suppliers who have experience handling similar projects, can meet your volume requirements, and employ modern practices to ensure efficiency. Taking time to find a reputable supplier now helps prevent headaches later.

What to do:

Review their portfolio and case studies to confirm they have handled comparable projects. Request examples of past work to verify expertise.

2. Financial and Legal Stability

Financial stability is a key indicator of a supplier or contractor's ability to deliver. A partner with strong financial health can maintain consistent material supply, keep equipment running, and manage their workforce without disruption.

What to do:

Request financial statements or conduct credit checks to verify stability. Confirm their licensing and compliance with relevant authorities.

3. Safety Standards and Certifications

A contractor's commitment to

safety directly influences worker well-being, project timelines, and overall success. Lapses can lead to preventable accidents and costly disruptions, as illustrated by the story of Royal Liverpool Hospital.

What to do:

Verify safety commitment by checking the Experience Modifier Rate (EMR) — a score below 1.0 shows better-than-average safety performance — and reviewing OSHA 300 logs for recurring incidents. Also, ask about company safety policies and whether a dedicated safety officer is in place.

4. Capacity and Resource Availability

Confirm that the contractor or supplier has the manpower, equipment, and materials to meet project deadlines.

What to do:

Assess their current workload and resources through discussions or site visits. Request details on their supply chain and staffing.

5. Reputation and References

Choose partners with a strong industry reputation for reliability and quality.

What to do:

Research online reviews, testimonials, and case studies. Contact previous clients to gather feedback on performance, timeliness, and professionalism.

Build reliable partnerships with suppliers

Streamline RFQs and approvals with FirstBit

Request a demo

Step-by-Step Process for Contractor & Supplier Selection

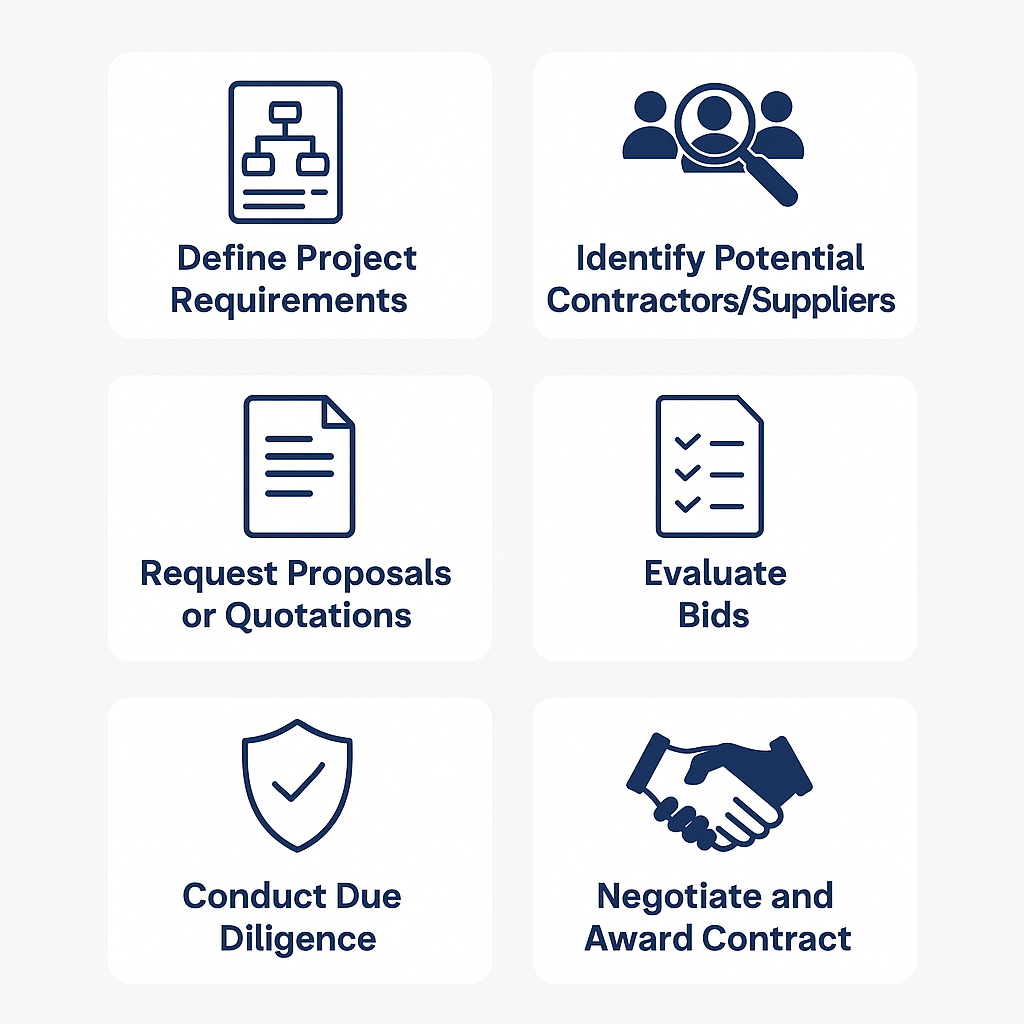

A structured selection process helps identify the best contractors and suppliers while minimizing risks. Here’s how to do it right:

1. Define Project Requirements

This step is about nailing down exactly what your project needs — scope, budget, timeline, and all the fine details. A clear plan ensures everyone’s on the same page from the start, preventing mismatched expectations or wasted time with unsuitable candidates. Without this, you risk bids that don’t fit or partners who can’t deliver.

How to do:

Draft a detailed project brief that spells out technical specs, quality standards, delivery schedules, and any special requirements, like sustainability goals. Use project management tools to organize and share this info clearly. Include measurable deliverables to set expectations and make it easier to evaluate proposals later.

For UAE-based projects, briefs must

include local regulations, such as Dubai Municipality building codes or Abu Dhabi’s planning standards. FirstBit ERP, used across the UAE, centralizes project data to help ensure documentation aligns with special requirements.

2. Identify Potential Contractors/Suppliers

This is where you build a shortlist of contractors or suppliers who can handle your project. It matters because starting with a strong pool of candidates increases your chances of finding a reliable partner. A broad search also sparks competition, which can lead to better offers and terms.

How to do:

Tap into industry directories, trade groups, or trusted referrals from colleagues to find firms with a solid track record. Online platforms can help you spot companies with relevant experience. Aim for a shortlist of three to five candidates to keep the process manageable but competitive.

3. Request Proposals or Quotations

Here, you ask shortlisted candidates to submit detailed proposals or quotes outlining how they’ll tackle your project. This step is key because it gives you a clear view of each firm’s approach, costs, and capabilities, letting you compare apples to apples. Well-structured requests keep responses consistent and relevant.

How to do:

Send out a Request for Proposal (RFP) or Request for Quotation (RFQ) that details the project scope, timeline, and evaluation criteria, like cost or technical expertise. Specify what you need in the response — such as work plans, timelines, or safety policies — to facilitate easier comparisons. Set a firm deadline for submissions.

4. Evaluate Bids

Evaluating bids is about picking the proposal that delivers the best value, not just the cheapest price. It’s crucial to avoid cutting corners that could lead to poor quality or delays. A fair, structured evaluation helps you choose a partner who aligns with your project’s goals.

How to do:

Create a scoring system that weighs factors like price, experience, technical skills, and proposed timelines. Rank each bid based on how well it meets your project brief, focusing on long-term value over low cost. If something’s unclear, set up meetings to clarify details with bidders.

To make this process smoother, digital tools such as First Bit’s ERP can simplify bid analysis by organizing data into dashboards, helping you compare proposals side-by-side.

5. Conduct Due Diligence

Due diligence involves thoroughly verifying the credentials, finances, and track record of your top candidates. It’s a must to avoid surprises like insolvency or non-compliance that could derail your project. This step builds confidence that your choice is solid.

How to do:

Dig into financial records, like balance sheets or credit reports, to confirm stability. Verify licenses, insurance (e.g., liability, workers’ comp), and certifications with relevant authorities. Call at least two references to check past performance and visit completed projects if you can, to see their work firsthand.

In the UAE, verifying a contractor’s registration with authorities such as the Dubai Municipality or the Department of Economic Development is essential for compliance with local laws. FirstBit ERP, designed for businesses operating in the region, helps manage this due diligence by storing and tracking compliance data directly in contractor and supplier profiles, making it easier to confirm credentials before awarding work.

6. Negotiate and Award Contract

This final step locks in your chosen contractor or supplier with a clear, binding agreement. It’s vital because a well-negotiated contract sets expectations, minimizes disputes, and protects both sides. A solid contract keeps the project on track.

How to do:

Sit down with your top pick to hammer out details like scope, budget, payment terms, and timelines. Push for clauses that cover delays, defects, or disputes — arbitration is a good option. Get a lawyer to review the contract to make sure it’s airtight.

Common Mistakes to Avoid in the Selection Process

Steering clear of these common pitfalls can save you significant headaches, time, and money down the line.

1. Choosing Based Solely on Price

While the temptation to choose the lowest bid may be strong, this approach often leads to disastrous results.

For example, imagine hiring a subcontractor based solely on price. They might use substandard materials that fail inspections or cut corners on safety, which could lead to costly site shutdowns and potential liabilities for you.

A client could hire a cheap contractor who delivers a project that looks good initially, but needs expensive repairs much sooner than expected because quality was sacrificed. The initial "savings" quickly turn into rework costs, project delays, and damaged reputations.

How to avoid:

Look beyond the initial price tag; evaluate bids by considering their experience, the quality they promise, their reliability, and the overall long-term value to prevent these costly surprises.

2. Not Checking References and Safety Records

Failing to review both performance history and safety practices can put your project at serious risk. Without reference checks, you might hire a contractor known for chronic delays, poor communication, or unfinished work — issues that past clients could have warned you about.

Ignoring safety records is equally risky; working with teams that have poor safety practices increases the chance of accidents, costly work stoppages, fines, higher insurance premiums, and legal liability.

How to avoid:

Contact previous clients for honest feedback on performance, timeliness, communication, and problem-solving. At the same time, review safety metrics such as Experience Modifier Rate (EMR) and OSHA 300 logs to ensure the contractor prioritizes safe work practices.

3. Failing to Verify Licenses and Certifications

Assuming a contractor or supplier has all the necessary, up-to-date credentials without checking can lead to serious trouble. Engaging an improperly licensed electrician, for instance, could void your insurance claim if faulty wiring causes a fire, or the work might fail inspections, requiring expensive deconstruction and rework to meet code. This oversight puts your project, finances, and legal standing at risk.

How to avoid:

Diligently verify all essential licenses and certifications directly with the relevant authorities to confirm they are current and valid before any work begins.

4. Not Considering Long-Term Relationships

Treating every selection as a one-time deal means you're constantly starting from scratch. This approach means missing out on the efficiencies, trust, and potentially preferential treatment (like better terms or prioritized service during busy periods) that come from established partnerships. For example, a reliable subcontractor you've worked with knows your standards and can integrate seamlessly, saving significant coordination time on future projects.

How to avoid:

Seek out and cultivate relationships with partners who demonstrate reliability, open communication, and a commitment to quality, as these collaborations can streamline future projects and offer better overall value.

Choose the best suppliers

Request a demo

How to Make Your Selection Process Smarter with Technology

Selecting the right contractors and suppliers takes time and careful judgment, but technology can simplify the process.

Technology can make your selection process faster and more efficient. Here’s how:

-

-

Data analytics. Use performance data —such as defect reports, delay logs, safety records, and quality scores—to identify reliable partners. Analytics tools track metrics such as delivery and quality.

-

E-Tendering systems. Go digital for transparency. Online systems streamline bids and ensure compliance.

-

Project management tools. Boost oversight with tools like Building Information Modeling (BIM). They improve coordination and cut errors.

Regional Considerations for the UAE

The United Arab Emirates (UAE) is a global hub for construction, with iconic projects like Dubai’s Burj Khalifa and Abu Dhabi’s sustainable developments setting high standards for quality, safety, and innovation. Selecting the right contractors and suppliers is critical to meeting these standards. Poor choices can lead to project delays, cost overruns, substandard work, or legal complications, all of which can harm a company’s reputation and financial health.

If you’re operating in the UAE, additional factors ensure compliance and alignment with local expectations:

-

-

Local partnerships. Prioritize Emirati-owned firms or joint ventures to support economic diversification, as is often favored in public tenders.

-

Cultural alignment. Understand local business practices, such as respect for timelines and communication protocols, to build strong relationships.

-

Achieve flawless teamwork

Coordinate roles and schedules through FirstBit ERP

Request a demo

How FirstBit ERP Helps You Choose the Right Partners

An integrated system like FirstBit ERP can offer significant advantages in how you approach the selection and ongoing management of contractors and suppliers, leading to more efficient operations and better project outcomes. Here’s how it can address common challenges:

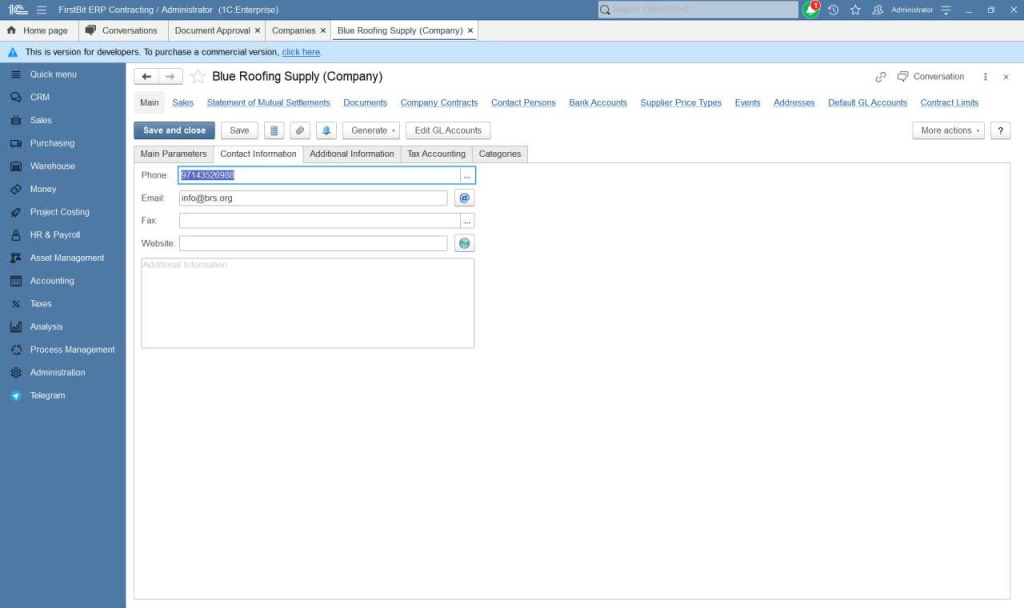

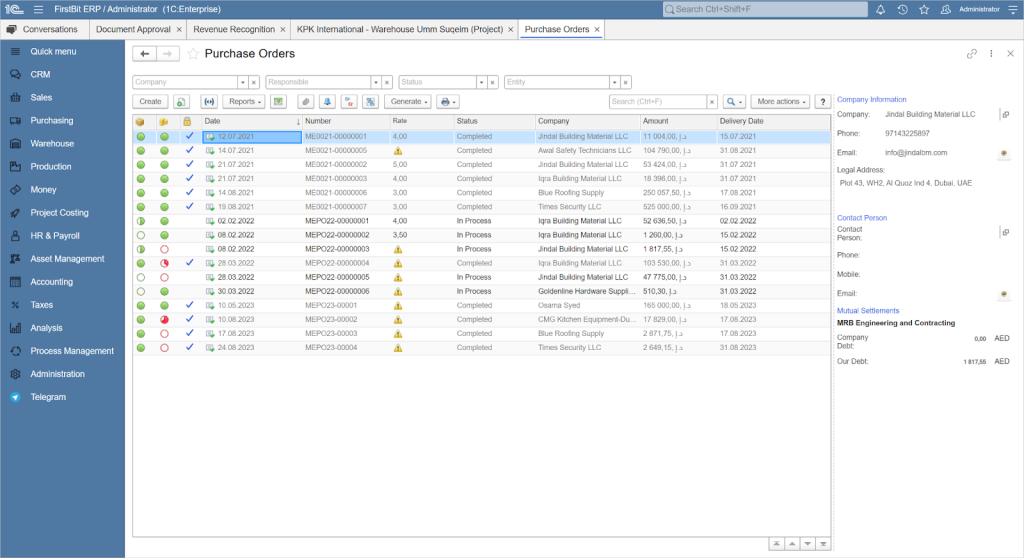

1. Source for Contractors & Suppliers Data

An ERP system helps solve selecting contractors and suppliers by bringing all partner information together. It allows you to maintain complete profiles with contacts, services offered, qualifications, project history, and correspondence, making it easier to analyze and choose the right partners for new projects.

The company’s contact information tab in FirstBit ERP

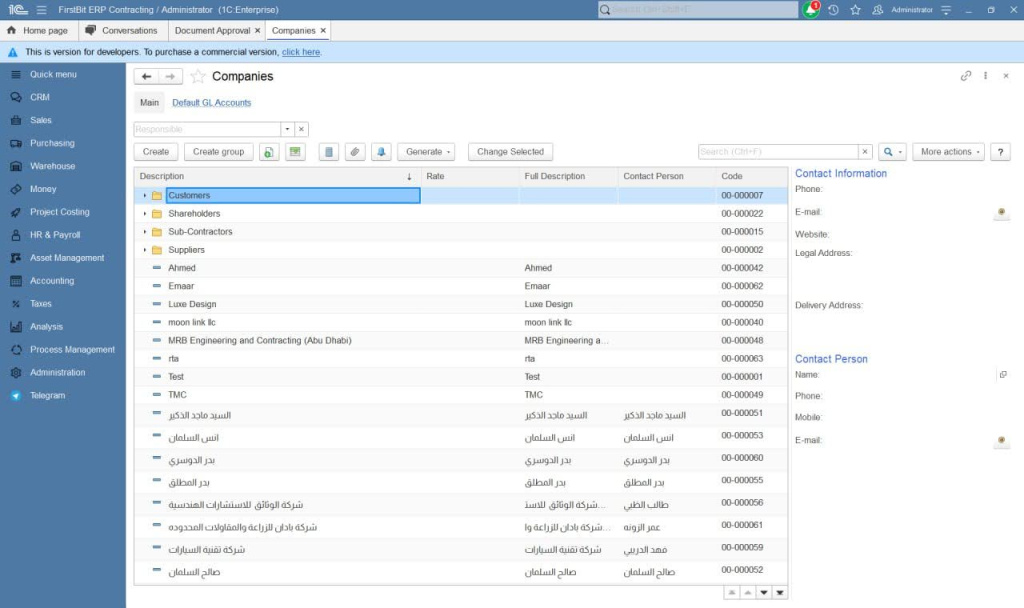

2. Efficient Bid & Tender Management

An ERP system can streamline this workflow by standardizing and automating key steps:

- Issuing tender documents. Automatically generate templates, attach scope details, and send them to selected vendors through the system’s integrated communication tools.

- Capturing and organizing incoming bids. Collect all submissions digitally, tag them to the correct project, and store them in a centralized, searchable database for quick comparison.

- Evaluating proposals against predefined criteria beyond just price. Use built-in scoring models to compare delivery timelines, compliance with safety standards, vendor experience, and previous performance ratings.

This creates a clear audit trail and supports more objective, transparent decision‑making — all within an integrated environment.

Companies’ profiles list in FirstBit ERP

3. Real-Time Project Cost Control & Visibility

Connect your supplier deals and orders directly to specific projects in the system. This way you’ll get a much clearer, live picture of:

- If you're over or under budget for that project.

- When you need to pay your suppliers for that project.

- How much each supplier is costing you for that project, and if it's a good deal for the project's finances.

FirstBit ERP is all about having clear financial control and visibility for each individual project by directly connecting the spending to the project itself.

Purchase Orders tab in FirstBit ERP

4. Performance Assessment & Tracking

Evaluating contractor and supplier performance often relies on scattered notes or subjective impressions, which can make it difficult to spot trends or hold partners accountable. Over time, this can lead to repeated issues with quality, delays, or poor responsiveness.

An ERP system helps by tracking key performance indicators (KPIs) such as schedule adherence, defect and rework rates, and responsiveness. With custom reports and dashboards, it becomes easier to see which partners consistently meet expectations and where improvements are needed, creating a structured, data‑driven foundation for future selection and collaboration..

Final Thoughts

The right contractors and suppliers bring trust, problem-solving skills, and the flexibility to handle unexpected challenges. Strong partnerships do more than keep projects on schedule; they create an environment where innovation thrives and issues are resolved before they escalate.

Over time, these relationships build a reliable network of expertise and support, adding long-term value that benefits every future project.

Ensure timely and profitable project completion with FirstBit

Request a demo

FAQ

1. How do I ensure compliance with local regulations when selecting contractors in the UAE?

Verify that contractors are registered with UAE authorities, such as the Dubai Municipality or Department of Economic Development. Check compliance with Federal Law No. 11 of 2023 for public projects and confirm licenses are valid.

3. Should I prioritize local firms in the UAE?

Partnering with Emirati-owned firms or joint ventures is often preferred, especially for public projects, to align with economic diversification goals. Check tender requirements for specific preferences.

4. What methods of contractor selection are considered the most effective?

This helps potential clients understand best practices for choosing reliable contractors, such as pre-qualification, interviews, and reference checks, ensuring they select partners who align with their project goals and values.

5. How can software help with contractor selection and project management?

Explaining the role of software in automating evaluations, tracking performance metrics, and streamlining communication reassures clients that technology can simplify complex processes and improve decision-making.

6. How can I verify a contractor’s safety standards in the UAE?

Request certifications like ISO 45001 and safety performance records. Ensure compliance with UAE safety regulations, such as those set by the Ministry of Human Resources and Emiratisation.

Anna Fischer

Construction Content Writer

Anna has background in IT companies and has written numerous articles on technology topics.